Preparation method of graphene oxide-polyaniline composite electromagnetic shielding material

A technology of composite electromagnetic and shielding materials, which is applied in the field of preparation of graphene oxide/polyaniline composite electromagnetic shielding materials, can solve the problems of increasing interface polarization and low conductivity between graphene oxide and polyaniline contact layers, and achieve good Electromagnetic wave shielding effectiveness, increased interface polarization, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Add 0.0204 g of graphene oxide and 35 mL of perchloric acid aqueous solution with a concentration of 1 mol / L into the reaction flask, treat with ultrasound for 30 min, then add 183 μL of aniline, stir magnetically for 30 min, and record it as solution I.

[0020] 2) Dissolve 0.3047 g of ammonium persulfate into 5 mL of perchloric acid aqueous solution with a concentration of 1 mol / L to form solution II.

[0021] 3) Then, solution I and solution II were mixed in an ice-water bath and reacted for 24 hours under stirring to obtain a dark green product dispersion. Washing with deionized water, absolute ethanol and acetone until pH 6-7 is close to neutral, filtering and drying to obtain dark green graphene oxide-polyaniline composite electromagnetic shielding powder material.

Embodiment 2

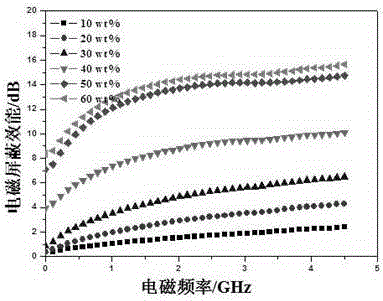

[0023] The powder material prepared in Example 1 is mixed with paraffin into samples with different contents, the mass percentages of the powder material are respectively 10wt%, 20wt%, 30wt%, 40wt%, 50wt% and 60wt%, and then it is respectively pressed into An annular piece with an outer diameter of 7mm, an inner diameter of 3.04mm and a thickness of 3mm was placed in the Maury2553T7.5 air line of the Agilent E5071c vector network analyzer for testing. The test results are as follows figure 1 shown.

Embodiment 3

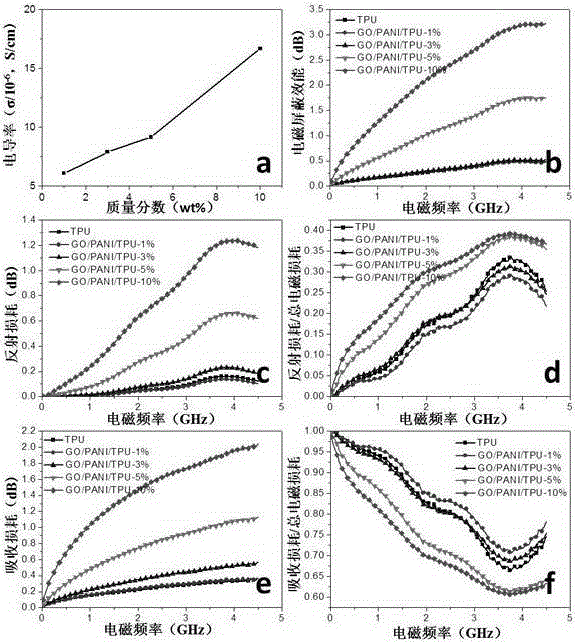

[0025] The powder material prepared in Example 1 was mixed with thermoplastic polyurethane (TPU) by solution mixing method to prepare sample films with different contents, the mass percentages of the powder material were 1wt%, 3wt%, 5wt% and 10wt%, and then Cut out a circular test film with an outer diameter of 7mm, an inner diameter of 3.04mm and a thickness of 2mm, and place it in the Maury2553T7.5 air line of the Agilent E5071c vector network analyzer for electromagnetic shielding effectiveness testing. The test results are as follows figure 2 b- figure 2 shown in f. Cut out a circular sheet with a diameter of 7mm on the corresponding film, and use the voltage-current method to test the conductivity of the corresponding film. The test results are as follows figure 2 as shown in a.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com