Aluminum-carbon carborundum brick for torpedo ladle and preparation method thereof

A technology of aluminum carbon silicon carbide bricks and torpedo tanks, which is applied in the field of shaped refractory materials, can solve the problems of high production cost of aluminum silicon carbide carbon bricks, reduce the high temperature strength of materials, and unfavorable material properties, so as to improve oxidation resistance and thermal shock Stability, reduction of porosity, improvement of erosion resistance and erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

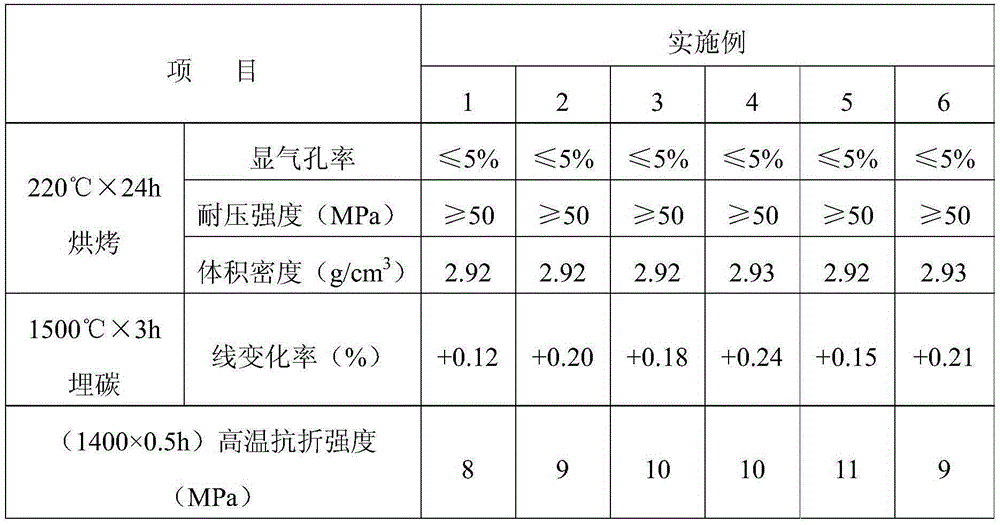

Examples

Embodiment 1

[0029] Aluminum carbon silicon carbide bricks for torpedo tanks 1 (Al 2 o 3 -C-SiC brick) raw materials by weight ratio by 71 parts of high alumina bauxite clinker particles, 10 parts of alumina powder, 3 parts of silicon carbide micropowder, 2 parts of industrial crystalline silicon, 10 parts of Composed of flake graphite and 4 parts of thermosetting phenolic resin.

[0030] The high alumina bauxite clinker particles are divided into three gradations according to the particle size: ≤5mm and >3mm, ≤3mm and >1mm, and ≤1mm and >0.088mm, and the weight percentages are 45%, 37% and 18% respectively .

[0031] In high alumina bauxite clinker particles, Al 2 o 3 The content of ≥88%, Fe 2 o 3 content≤2.0%, TiO 2 The content of ≤4.0%, K 2 O+Na 2 O content≤0.4%, CaO+MgO content≤0.4%.

[0032] The particle size of high alumina bauxite powder is ≤0.088mm.

[0033] The particle size of silicon carbide micropowder is ≤3μm, the content of SiC is ≥96%, Fe 2 o 3 The content of ≤1...

Embodiment 2

[0037] Aluminum carbon silicon carbide bricks for torpedo tanks 2 (Al 2 o 3 -C-SiC brick) raw materials by weight ratio by 64 parts of high alumina bauxite clinker particles, 12 parts of alumina powder, 6 parts of silicon carbide micropowder, 3 parts of crystalline silicon, 12 parts of scale Composed of graphite and 3 parts of thermosetting phenolic resin.

[0038] High alumina bauxite clinker particles are divided into three gradations of ≤5mm and >3mm, ≤3mm and >1mm, and ≤1mm and >0.088mm according to the particle size, and the weight percentages are 48%, 28% and 24% respectively .

[0039] Above-mentioned raw material is identical with the raw material of embodiment 1.

Embodiment 3

[0041] Aluminum carbon silicon carbide bricks for torpedo tanks 3 (Al 2 o 3 -C-SiC brick) raw materials by weight ratio by 65 parts of high alumina bauxite clinker particles, 14 parts of high alumina bauxite powder, 4 parts of silicon carbide micropowder, 4 parts of crystalline silicon, 10 parts Composed of flake graphite and 3 parts of thermosetting phenolic resin.

[0042] High alumina bauxite clinker particles are divided into three gradations according to particle size: ≤5mm and >3mm, ≤3mm and >1mm, and ≤1mm and >0.088mm, and the weight percentages are 50%, 30% and 20% respectively .

[0043] Above-mentioned raw material is identical with the raw material of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com