Stirring-type liquid magnetization device

A stirring and liquid technology, applied in the field of magnetization, can solve the problem of mass production of magnetized water and achieve the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

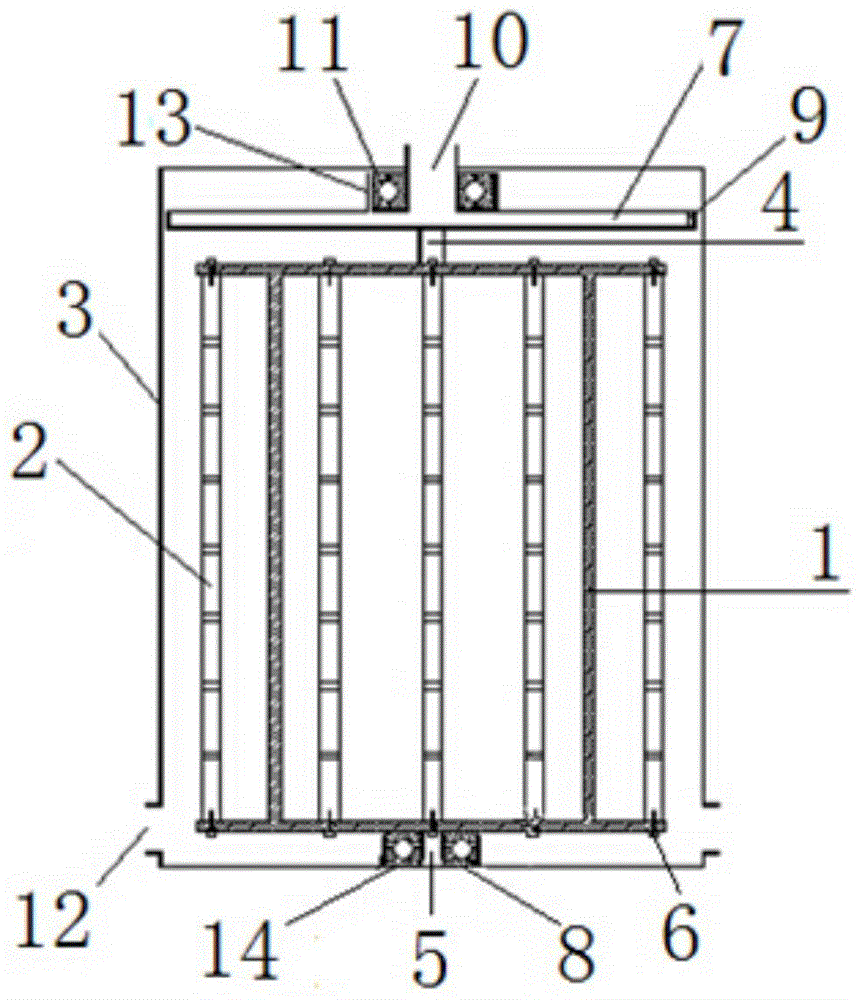

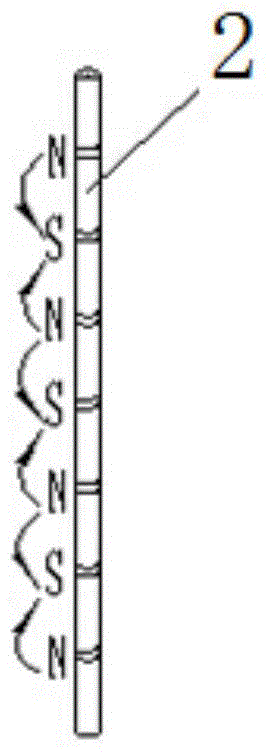

[0028] Such as figure 1 As shown, the stirring type liquid magnetization device of the present invention includes a main body support 1, a magnetic column 2, a housing shell 3, a coupling structure 4 and a rotating shaft 5, wherein the magnetic force column 2 is installed on the main body support 1, and the main body support 1 is arranged on the housing shell Inside the body 3 , the coupling structure 4 is arranged above the main body support 1 , and the rotating shaft 5 is arranged below the center of the main body support 1 .

[0029] Such as figure 2 As shown, the main body bracket 1 is a stainless steel duplex structure, including an upper beam and a lower beam. The connecting structure 4 is arranged in the center of the upper beam, the rotating shaft 5 is arranged in the center of the lower beam, and several assembly holes 6 are distributed on the upper beam and the lower beam. The magnetic column 2 is installed on the assembly hole 6 . The main frame also includes a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com