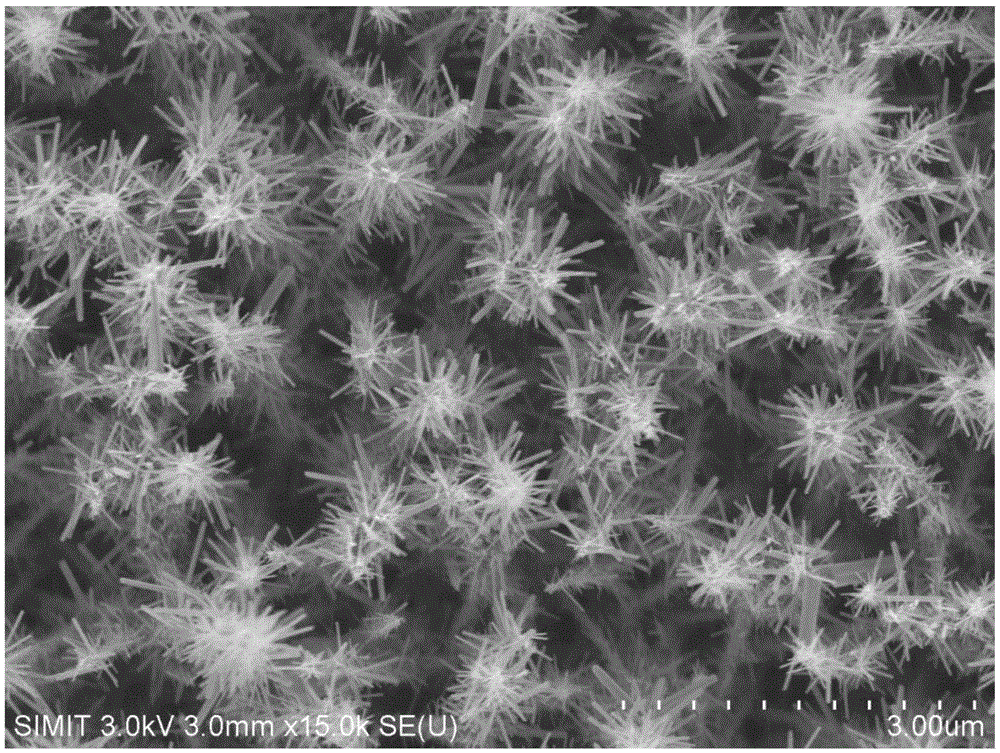

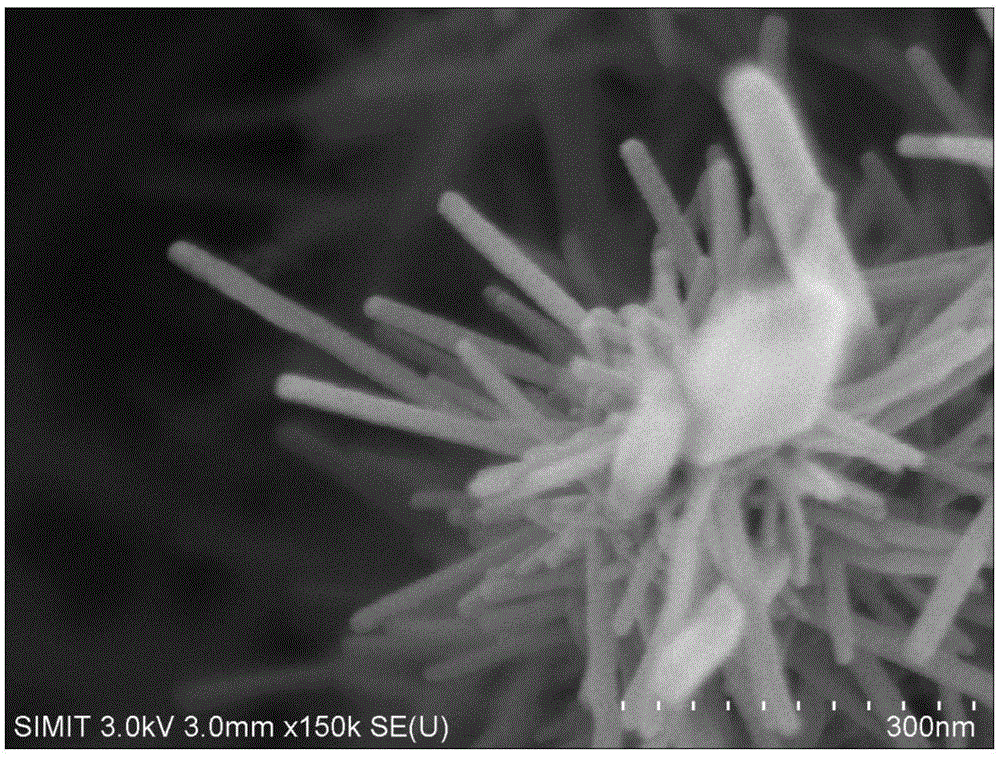

Preparation method of dendritic zinc oxide nanowire array

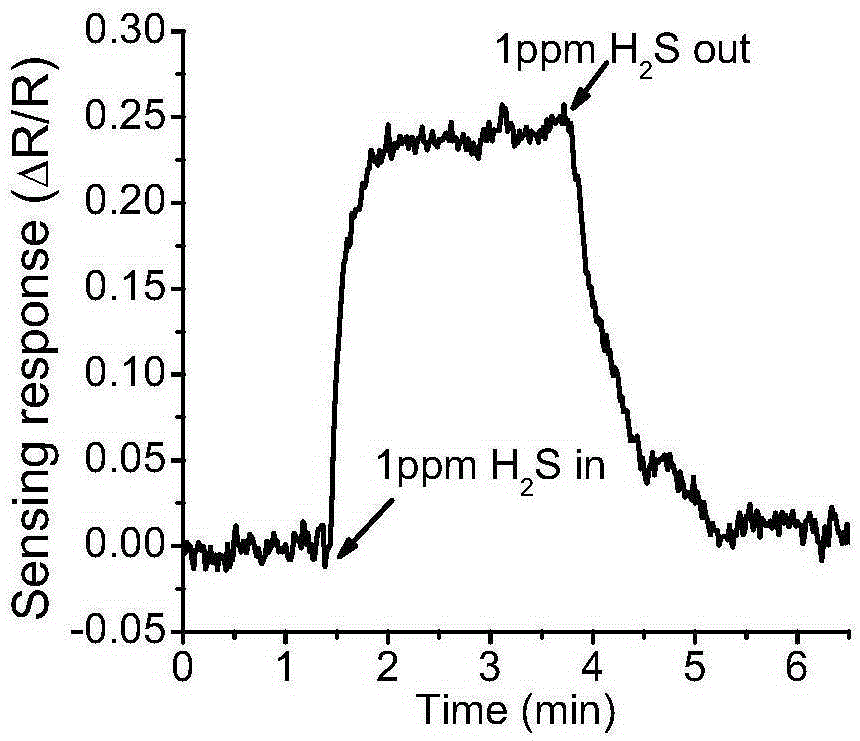

A technology of zinc oxide nanowires and zinc oxide seed layers is applied in the field of preparation of zinc oxide nanowire arrays, which can solve the problems of poor density of nanowires, poor uniformity of nanowires, damaged device structure, etc., and achieves good repeatability and good repeatability. The effect of uniformity, low preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The invention provides a method for preparing a dendritic zinc oxide nanowire array, comprising the following steps:

[0067] 1) cleaning the substrate surface;

[0068] 2) Depositing a zinc oxide seed layer on the surface of the substrate by atomic layer deposition;

[0069] 3) growing zinc oxide nanowire arrays on the substrate by hydrothermal method;

[0070] 4) After cleaning and drying the substrate after completing step 3), a rod-shaped zinc oxide nanowire array is formed;

[0071] 5) Depositing a zinc oxide seed layer on the surface of the substrate after step 4) by using an atomic layer deposition process;

[0072] 6) Steps 3)-4) are repeated to form dendritic zinc oxide nanowire arrays.

Embodiment 1

[0075] The present invention prepares a dendritic zinc oxide nanowire array, specifically comprising the following steps:

[0076] (1) The substrate was ultrasonically washed with acetone, ethanol, and deionized water for 5 minutes, respectively, and dried.

[0077] (2) Use the atomic layer deposition equipment model Kemin EPEALD-S150A, adopt the thermal atomic layer deposition process, and deposit a layer of zinc oxide seed layer with a thickness of 100nm on the substrate surface; the precursors used are diethyl zinc and Water, the substrate temperature during deposition is 150°C, the deposition thickness of each deposition cycle is 0.15nm, and the number of deposition cycles is 667 times.

[0078] (3) Immerse the substrate in the aqueous solution of the precursor of zinc oxide, seal it, and grow the array of zinc oxide nanowires using the hydrothermal method, control the temperature at 90° C., and grow at a constant temperature for 4 hours; The solution is calculated to con...

Embodiment 2

[0084] The present invention prepares a dendritic zinc oxide nanowire array, specifically comprising the following steps:

[0085] (1) Clean the substrate for 1-2 minutes using plasma with a power of 18W, an oxygen flow rate of 50ml / min, and a vacuum degree of 100Pa in the cavity of the plasma machine.

[0086] (2) Using the atomic layer deposition equipment model Kemin EPEALD-S150A, a plasma-enhanced deposition process is used to deposit a 150-nanometer-thick zinc oxide seed layer on the surface of the substrate; the precursors used are diethyl zinc and oxygen , the substrate temperature during deposition is 150°C, the deposition power is 150W, the deposition thickness of each deposition cycle is 0.15nm, and the number of deposition cycles is 1000 times.

[0087] (3) Immerse the substrate in the aqueous solution of the precursor of zinc oxide, seal it, and grow the array of zinc oxide nanowires using the hydrothermal method, control the temperature at 90° C., and grow at a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com