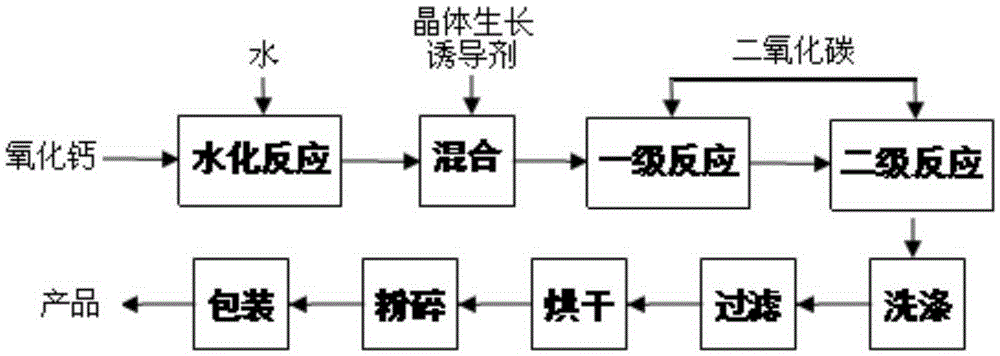

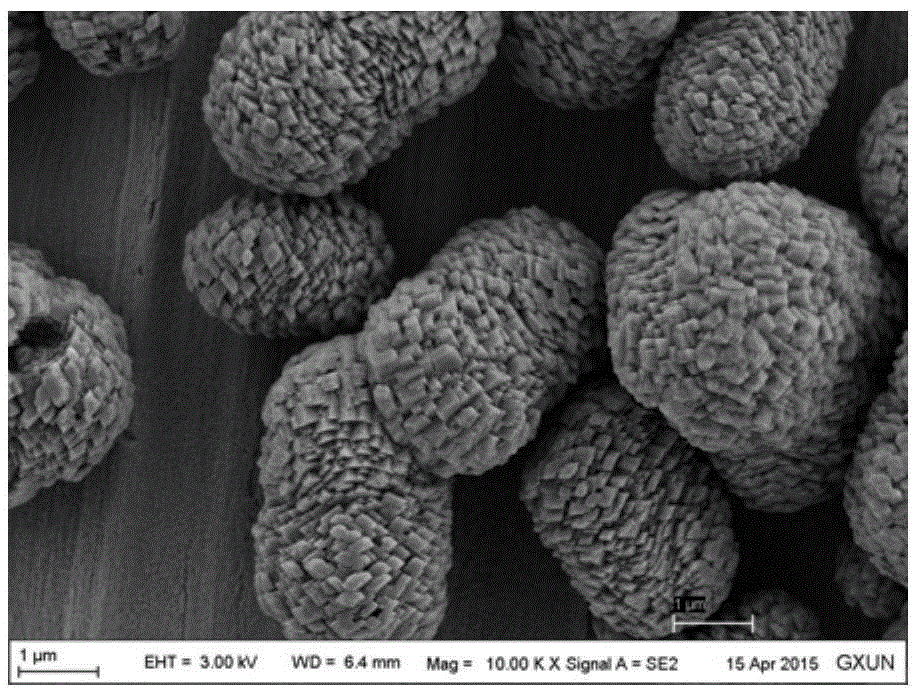

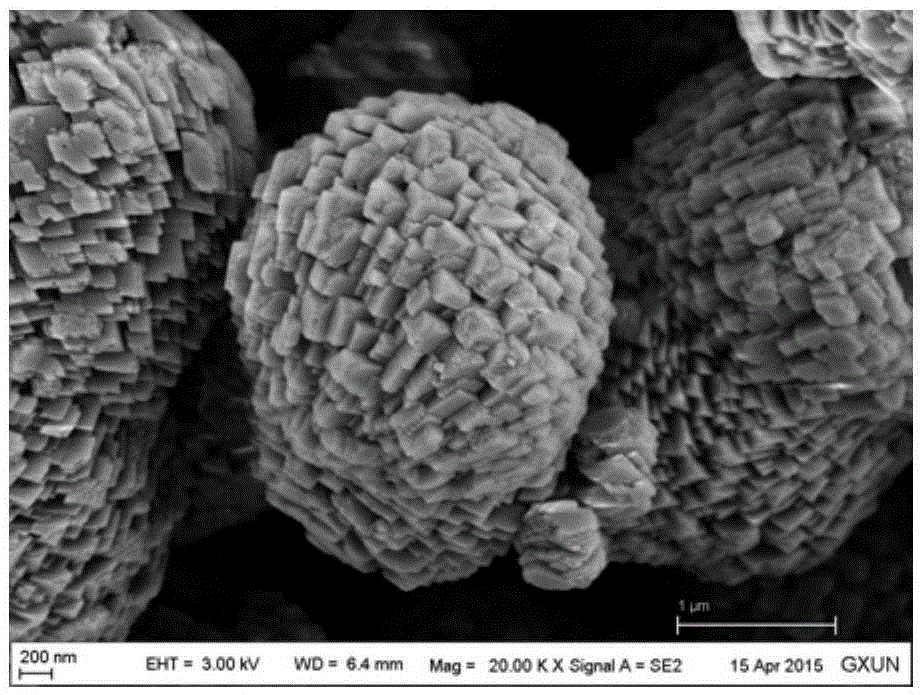

Preparation method of pine-cone-shaped calcite type micron-size calcium carbonate particles

A calcite-type, micron-level technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems such as the report of micron-level calcium carbonate with no pine cone shape, achieve good social and ecological benefits, reduce dosage, and reduce emissions and processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Raw material composition and mass quantity:

[0034] 60 parts of calcium oxide, 2 parts of compound crystal growth control agent, 900 parts of water, appropriate amount of carbon dioxide.

[0035] The mass ratio of the components of the above crystal growth composite control agent is: sodium p-styrene sulfonate: sodium methylene bis-naphthalene sulfonate: alkyl naphthalene sulfonate = 0.2: 0.3: 0.5 mixture.

[0036] 2. Preparation method:

[0037]Dissolve 60 parts of calcium oxide in 900 parts of water, undergo hydration reaction, let stand for 24 hours and then filter to prepare Ca(OH) 2 Put the suspension into the carbonization reactor, then add the aqueous solution of the crystal growth composite control agent, and stir at 50°C and 500r / min, and set the flow rate to 90m 3 / (h·m 3 Suspension) of CO 2 The gas distributor that passes into the bottom of the carbonization reactor reacts with calcium hydroxide, and when the reaction slurry pH=8.5, the CO2 flow rate ...

Embodiment 2

[0039] 1. Raw material composition and mass quantity:

[0040] 60 parts of calcium oxide, 4.5 parts of compound crystal growth control agent, 1500 parts of water, appropriate amount of carbon dioxide.

[0041] The crystal growth composite control agent mentioned above is a mixture of sodium p-styrene sulfonate: sodium methylene bis-naphthalene sulfonate: alkylnaphthalene sulfonate=0.2:0.1:0.7.

[0042] 2. Preparation method:

[0043] Dissolve 60 parts of calcium oxide in 1500 parts of water, undergo hydration reaction, let stand for 18 hours and filter to prepare Ca(OH) 2 Put the suspension into the carbonization reactor, then add the aqueous solution of the crystal growth composite control agent, under the stirring action of 95°C and 600r / min, the flow rate is 120m 3 / (h·m 3 Suspension) of CO 2 Pass into the gas distributor at the bottom of the carbonization reactor to react with calcium hydroxide, when the pH of the reaction slurry=9, the CO 2 Velocity reduced to 80m 3...

Embodiment 3

[0045] 1. Raw material composition and mass quantity:

[0046] 60 parts of calcium oxide, 3.5 parts of compound crystal growth control agent, 1200 parts of water, appropriate amount of carbon dioxide.

[0047] The compound crystal growth control agent described above is a mixture of sodium p-styrene sulfonate: sodium methylene bis-naphthalene sulfonate: alkylnaphthalene sulfonate=0.3:0.1:0.6.

[0048] 2. Preparation method:

[0049] Dissolve 60 parts of calcium oxide in 1200 parts of water, undergo hydration reaction, let stand for 20 hours and then filter to prepare Ca(OH) 2 Put the suspension into the carbonization reactor, then add the aqueous solution of the crystal growth composite control agent, under the stirring action of 80°C and 550r / min, the flow rate is 110m 3 / (h·m 3 Suspension) of CO 2 Pass into the gas distributor at the bottom of the carbonization reactor to react with calcium hydroxide, and when the pH of the reaction slurry=8.3, the CO 2 Velocity reduced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com