Brake-by-wire and pedal-force feedback system and braking method

A technology of brake-by-wire and feedback system, which is applied in the direction of brake transmission, brake, transportation and packaging, etc. It can solve problems such as bad feeling, pedal vibration, pressure coupling, etc., avoid processing difficulty and leakage problems, and realize independent The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

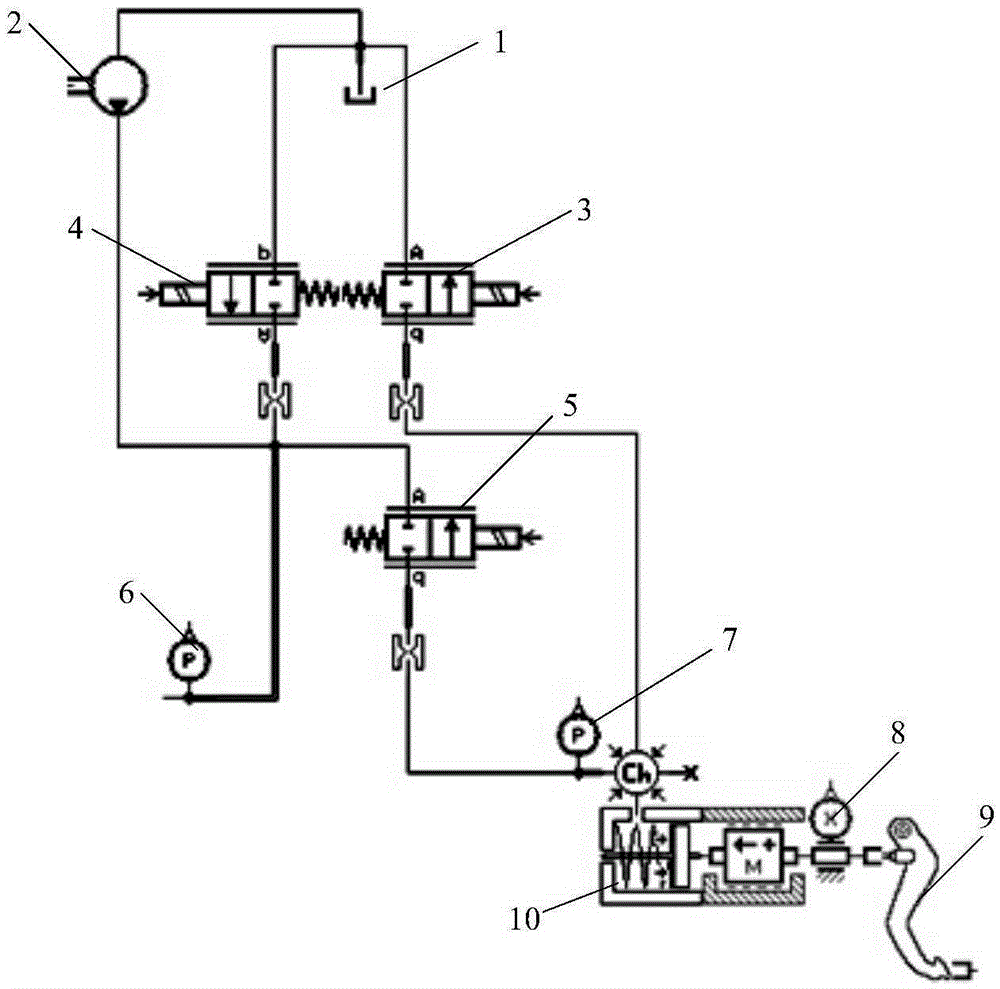

[0024] Such as figure 2 As shown, the inlet of the plunger pump 2 is connected to the outlet of the liquid storage tank 1, the brake master cylinder 10 is connected to the brake pedal 9, and the brake pedal 9 is provided with a displacement sensor 8 for detecting the displacement and acceleration of the brake pedal 9, and the brake The working chamber of the master cylinder 10 is respectively connected to the outlet of the plunger pump 2 and the inlet of the liquid storage tank 1. A drain valve 3 as a draining device is provided between the working chamber and the inlet of the liquid storage tank 1. The master cylinder pressure sensor 7 for the master cylinder pressure, and a liquid replenishment valve as a liquid replenishment device are arranged between the working chamber and the outlet of the plunger pump 2 . The reflux valve 4 used as a reflux device is respectively connected to the outlet of the plunger pump 2 and the inlet of the liquid storage tank 1, and the system p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com