Guide mechanism for reinforcing bar mesh welding

A guiding mechanism and steel mesh technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inaccurate positioning of steel bars, low standardization, poor welding quality, etc., and achieve reasonable design and use. Convenient and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

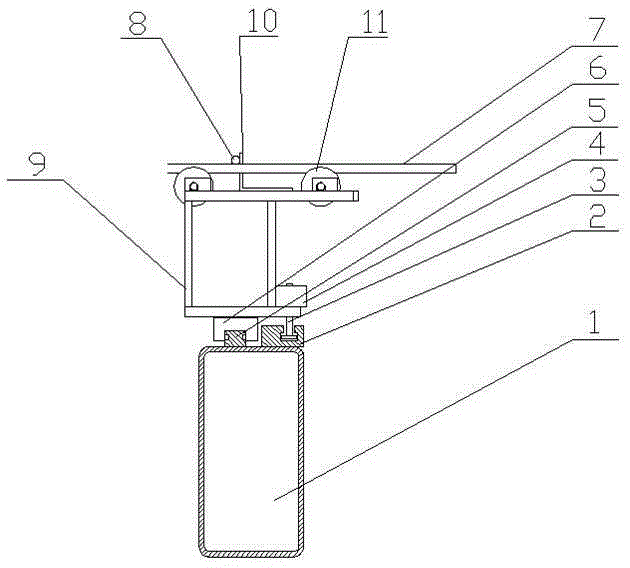

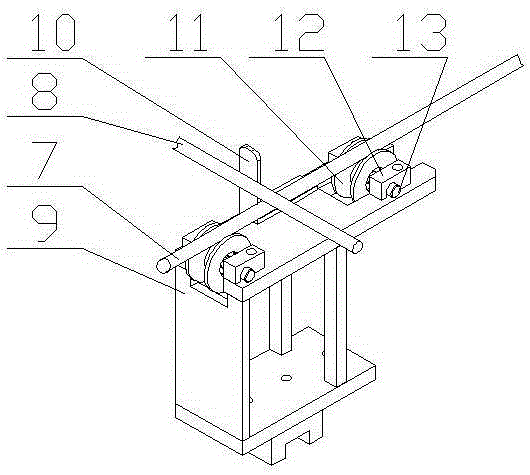

[0014] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment comprises a guide seat 9, a limit seat 10, a fixed beam 1, a roller 11 and a guide seat fixing device; a slide block 6 is installed below the guide seat 9, and a linear guide rail 5 and a slide block 6 are installed above the fixed beam 1 It is slidingly connected with the linear guide rail 5; a freely rotatable roller 11 is arranged above the guide seat 9, and a vertical steel bar 7 is placed on the roller 11, and the roller 11 is installed on the wheel shaft 13, and the wheel shaft 13 is fixed on the guide seat 9 through a pressure block Above, the roller 11 is provided with a V-shaped groove that limits the rolling of the vertical steel bar 7; the limit seat 10 is fixed above the guide seat 9, and the transverse steel bar 8 is clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com