Method for achieving aggregation of waste incineration fly ash through microorganism mineralization

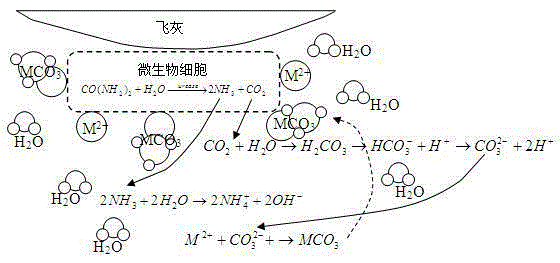

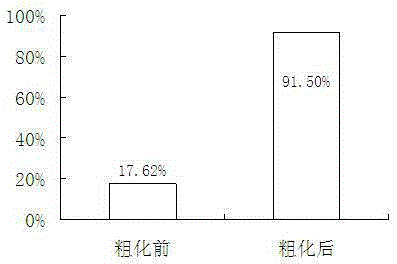

A waste incineration fly ash and mineralization technology, which is applied in the field of fly ash agglomeration, can solve the problems of difficulty in finding a universal chelating agent, high cost, and large capacity expansion ratio, so as to facilitate the formation, crystallization, and leaching Effect of reducing toxicity and reducing leaching toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

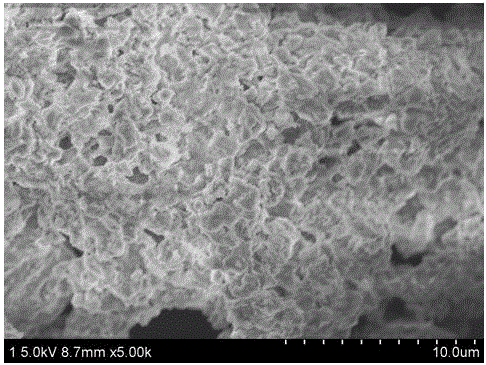

Method used

Image

Examples

Embodiment 1

[0036] Step 1) Prepare culture medium

[0037] Prepare the culture medium (the culture medium components are shown in Table 1), sterilize at 121°C high temperature, 103kPa high pressure, 20min, let it stand to room temperature, and put Sporosarcinapasteurii (purchased from China General Microorganism Culture Collection Center, No. cgmcc1.3687) was inoculated into a Erlenmeyer flask containing a culture medium at a 1% (v / v) inoculation amount, and cultured on a shaker at 30°C and 220r / min for 46h.

[0038] Table 1 Medium composition

[0039]

[0040] Bacteria solution OD 600 measurement of value

[0041] Bacteria concentration in OD 600The value is expressed, and its value is measured by a UV spectrophotometer. Take 1mL of the bacterial solution cultured on the shaking table (ensure that the operation of the bacterial solution is completed in a sterile environment to avoid contamination of the bacterial solution), and inject it into the culture tube immediately. Take 2 ...

Embodiment 2

[0047] Step 1) Prepare culture medium

[0048] Prepare the culture medium (the composition of the culture medium is shown in Table 1), sterilize at 121°C high temperature, 103kPa high pressure, 15min, and let it stand to room temperature. Culture Collection Center, No. cgmcc1.6503) was inoculated into a Erlenmeyer flask containing medium at a 1% (v / v) inoculum amount, and cultured on a shaker at 20°C and 240r / min for 24h.

[0049] Table 1 Medium composition

[0050]

[0051] Bacteria solution OD 600 measurement of value

[0052] Bacteria concentration in OD 600 The value is expressed, and its value is measured by a UV spectrophotometer. Take 1mL of the bacterial solution cultured on the shaking table (ensure that the operation of the bacterial solution is completed in a sterile environment to avoid contamination of the bacterial solution), and inject it into the culture tube immediately. Take 2 μL of each sample and measure its OD with a UV spectrophotometer 600 value...

Embodiment 3

[0057] Step 1) Prepare culture medium

[0058] Prepare the culture medium (the composition of the culture medium is shown in Table 1), sterilize at 121°C high temperature, 103kPa high pressure, 20min, let it stand to room temperature, and put Bacillus lentus (purchased from China General Microorganism Culture Collection) on the ultra-clean bench. Center, No. cgmcc1.4082) was inoculated into a Erlenmeyer flask containing medium at a 1% (v / v) inoculation amount, and cultured on a shaker at 35° C. and 180 r / min for 48 hours.

[0059] Table 1 Medium composition

[0060]

[0061] Bacteria solution OD 600 measurement of value

[0062] Bacteria concentration in OD 600 The value is expressed, and its value is measured by a UV spectrophotometer. Take 1mL of the bacterial solution cultured on the shaking table (ensure that the operation of the bacterial solution is completed in a sterile environment to avoid contamination of the bacterial solution), and inject it into the culture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com