Process equipment for preparing gypsum

A process equipment, gypsum technology, applied in the separation of dispersed particles, chemical/physical/physical-chemical processes, chemical instruments and methods, etc., can solve the problems of poor stability of gypsum desulfurization process, difficult to handle and utilize gypsum, etc. Up to standard, low cost, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

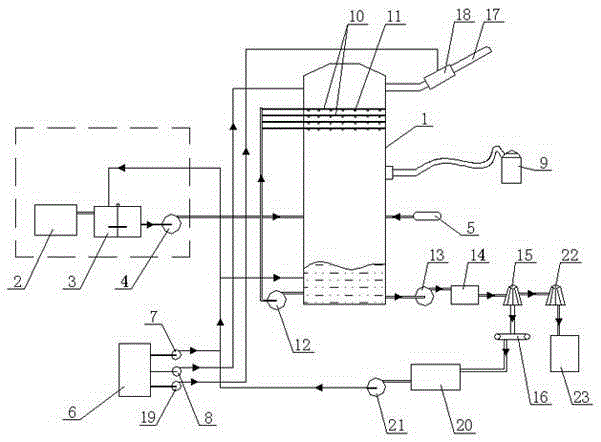

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] Such as figure 1 As shown, a process equipment for making gypsum is prepared by using the absorption tower 1 used in flue gas desulfurization, and the absorption tower 1 here is an existing equipment. In the preparation method of the present invention, also comprise limestone slurry forming mechanism, described limestone slurry forming mechanism is made of pulverizer 2 and limestone slurry pool 3, the pulverizer 2 here can select multiple models and products for use, as mine Mongolian mill, high-pressure suspension roller mill, high-pressure micro-powder mill, etc., the pulverizer 2 pulverizes the limestone raw material to obtain lime powder, and the lime powder is transported to the limestone slurry pool 3 through pipelines, and the lime powder is Lime slurry is formed after being stirred in the limestone slurry tank 3 , the mass ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com