Method of quickly repairing demineralized dentine

A technology of mineral teeth and essence, applied in the field of biomaterials, can solve problems such as lack of clinical practicability and complexity, achieve good biocompatibility, restore hierarchical structure, and prevent demineralization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

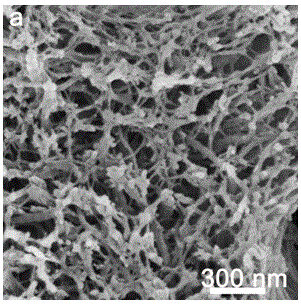

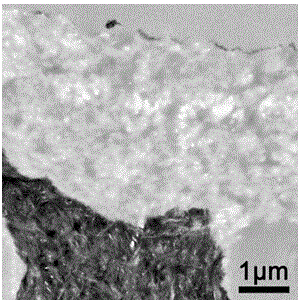

[0025]Equipped with 0.25M calcium chloride (CaCl2) aqueous solution, 0.15M disodium hydrogen phosphate (Na2HPO4) aqueous solution, and 10g / L polyacrylic acid (PAA) aqueous solution as the mother liquor for the synthesis experiment. Mix 2.4mL Na2HPO4 mother liquor and 3.30mL PAA mother liquor, dilute with double distilled water, adjust the pH to 9.5±0.1 with 1M NaOH aqueous solution, stir at room temperature for 0.5h, and the total volume is 30mL. Take 2.4mL CaCl2 mother liquor and add water to dilute to 30mL. Add 30mL of calcium solution 30 to 30mL of phosphorus solution with a burette, stir with a magnetic stirrer during the dropwise addition, and keep the pH in the range of 9.5±0.5 by adjusting the pH with 0.1M NaOH solution. Finally, the calcium ion concentration was 10.0 mM, the phosphorus ion concentration was 6.0 mM, and the PAA concentration was 50 ug / mL. Ensure that the entire dropping process lasts for 25 to 30 minutes. Collect caries-free isolated teeth, use a slow...

Embodiment 2

[0027] Equipped with 0.25M calcium chloride (CaCl 2 ) aqueous solution, 0.15M disodium hydrogen phosphate (Na 2 HPO 4 ) aqueous solution, 10g / L polyacrylic acid (PAA) aqueous solution was used as the mother liquor for the synthesis experiment. Mix 2.4mL Na2HPO4 mother liquor and 1.2mL PAA mother liquor, dilute with double distilled water, adjust the pH to 9.5±0.1 with 1M NaOH aqueous solution, stir at room temperature for 0.5h, and the total volume is 30mL. Take 2.4mL CaCl 2 Dilute the mother liquor with water to 30mL. Add 30mL of calcium solution 30 to 30mL of phosphorus solution with a burette, stir with a magnetic stirrer during the dropwise addition, and keep the pH in the range of 9.5±0.5 by adjusting the pH with 0.1M NaOH solution. Finally, the calcium ion concentration was 10.0 mM, the phosphorus ion concentration was 6.0 mM, and the PAA concentration was 200 ug / mL. Ensure that the entire dropping process lasts for 25 to 30 minutes. Collect caries-free isolated te...

Embodiment 3

[0029] Equipped with 0.25M calcium chloride (CaCl 2 ) aqueous solution, 0.15M disodium hydrogen phosphate (Na 2 HPO 4 ) aqueous solution, 10g / L polyacrylic acid (PAA) aqueous solution was used as the mother liquor for the synthesis experiment. Take 2.4mLNa 2 HPO 4 The mother liquor was mixed with 2.1mL of PAA mother liquor, diluted with twice distilled water, adjusted to pH 9.5±0.1 with 1M NaOH aqueous solution, stirred at room temperature for 0.5h, and the total volume was 30mL. Take 2.4mL CaCl2 mother liquor and add water to dilute to 30mL. Add 30mL of calcium solution 30 to 30mL of phosphorus solution with a burette, stir with a magnetic stirrer during the dropwise addition, and keep the pH in the range of 9.5±0.5 by adjusting the pH with 0.1M NaOH solution. The final concentrations of calcium ions and phosphorus ions were 10.0 mM and 6.0 mM, respectively. Finally, the calcium ion concentration was 10.0 mM, the phosphorus ion concentration was 6.0 mM, and the PAA conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com