Special cover board for bus duct

A technology of bus duct and cover plate, applied in the direction of cooling bus device, fully enclosed bus device, etc., can solve the problems of reducing the service life of the bus duct, difficult to ventilate, and difficult to dissipate heat from the bus duct.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

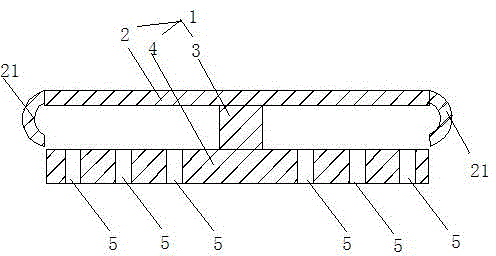

[0011] As shown in the figure, a special cover plate for bus duct includes a body 1, wherein the body 1 is an integrated structure, including a first horizontal plate 2, a connecting support plate 3 and a second horizontal plate 4, the first horizontal plate A horizontal plate 2 and a second horizontal plate 4 are connected through a connecting support plate 3, the body 1 is in the shape of an "I" shape; two ends of the first horizontal plate 2 are respectively provided with an arc-shaped edge 21, and the The arc-shaped sides 21 are semicircular, and the two arc-shaped sides 21 are axisymmetrically arranged; the second horizontal plate 4 is provided with a plurality of ventilation holes 5, and the ventilation holes 5 are formed in the second horizontal plate 4. Vertically arranged, the ventilation holes 5 are evenly distributed in the second horizontal plate 4; the number of the ventilation holes 5 is not less than 20; the shape of the ventilation holes 5 is one of circular, tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com