Analysis method of fission gas

A fission gas and analysis method technology, applied in the field of nuclear fuel post-irradiation inspection, can solve problems such as fuel irradiation swelling, affecting the performance of fuel elements, threats to reactor safety operation, etc., and achieve the effect of simplifying the separation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Such as Figure 5 Shown, a kind of analysis method of fission gas, described analysis method is to adopt gas chromatograph to carry out component content analysis to sample fission gas, described analysis method comprises the following steps of carrying out in sequence:

[0034] a. Collect the fission gas and collect the above fission gas in the sampling container;

[0035] b. Use the fission gas extraction tool to extract a specific volume of fission gas from the above sampling container, and send the above specific volume of fission gas into a gas chromatograph for gas chromatographic analysis;

[0036] c. After completing the gas chromatographic analysis of step b, extract fission gas equivalent to the specified volume from the above sampling container, and send the extracted fission gas into a gas chromatograph for gas chromatographic analysis;

[0037] e, calculate the ratio of the target component amount in the specific volume of fission gas taken in the sampling...

Embodiment 2

[0045] This embodiment further defines or provides a specific implementation on the basis of the fuel assembly provided in Embodiment 1. In order to further verify the reliability of the previous two consecutive measurements, between steps c and e, multiple A sampling measurement step, the sampling measurement step is to repeatedly extract fission gas equivalent to the specified volume from the above sampling container more than once after the completion of step c, and perform gas chromatographic analysis on the fission gas extracted each time . If the ratio of the amount of the target component in the fission gas of the specific volume taken in the sampling container is equal or approximately equal to the ratio of the peak area of the target component in the two gas chromatographic analysis results for two consecutive times in the multiple sampling measurement step, then it can be A reliable conclusion can be drawn from the previous measurement results, so that the peak are...

Embodiment 3

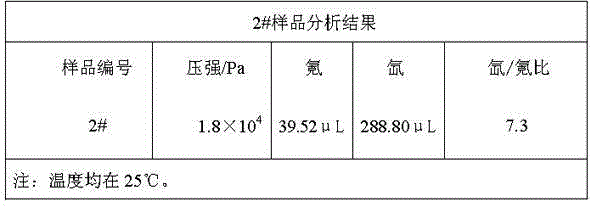

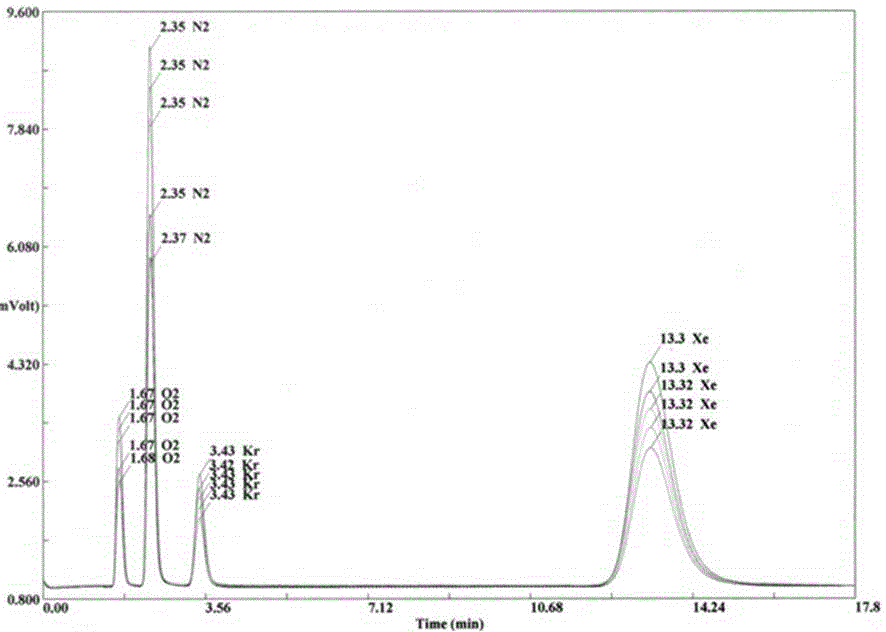

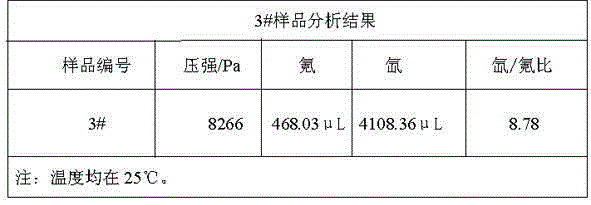

[0056] Such as figure 1 and figure 2 As mentioned above, this embodiment provides a specific chromatographic analysis method for a certain sample fission gas, the column temperature is 100°C; the inlet temperature is 120°C; the detector temperature is 140°C; the filament temperature is 220°C; helium is the carrier gas , purity ≥ 99.995%; carrier gas flow rate 30ml / min; reference gas flow rate 30ml / min; makeup gas flow rate 10ml / min; fission gas. Precisely measure 0.3 μL, 1.2 μL, 20 μL, 50 μL and 100 μL of krypton and xenon standard gases respectively, analyze according to the conditions, and use the injection volume V (μL) of the target gas to make a linear regression on the corresponding peak area S. The obtained sample analysis results are as follows figure 1 As shown, in the present embodiment, the continuous measurement method provided in Example 1 has been used for multiple measurements, and the obtained chromatogram overlay results are as follows figure 2 shown.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com