Micro-silicon resonance accelerometer with temperature stress compensation and vibration decoupling capabilities

A technology of temperature stress and accelerometer, applied in the direction of speed/acceleration/shock measurement, gyro effect for speed measurement, gyroscope/steering sensing equipment, etc., can solve the problem of sensitivity dead zone, achieve suppression of common mode interference, and achieve temperature Effects of stress compensation and processing technology compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

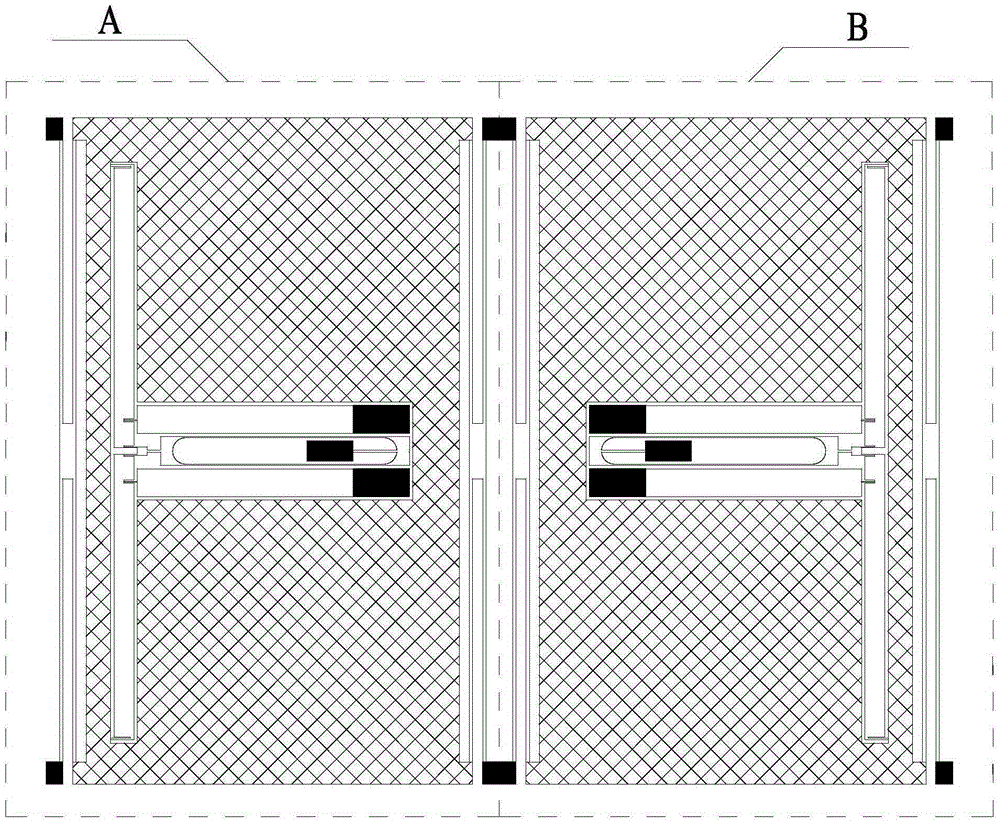

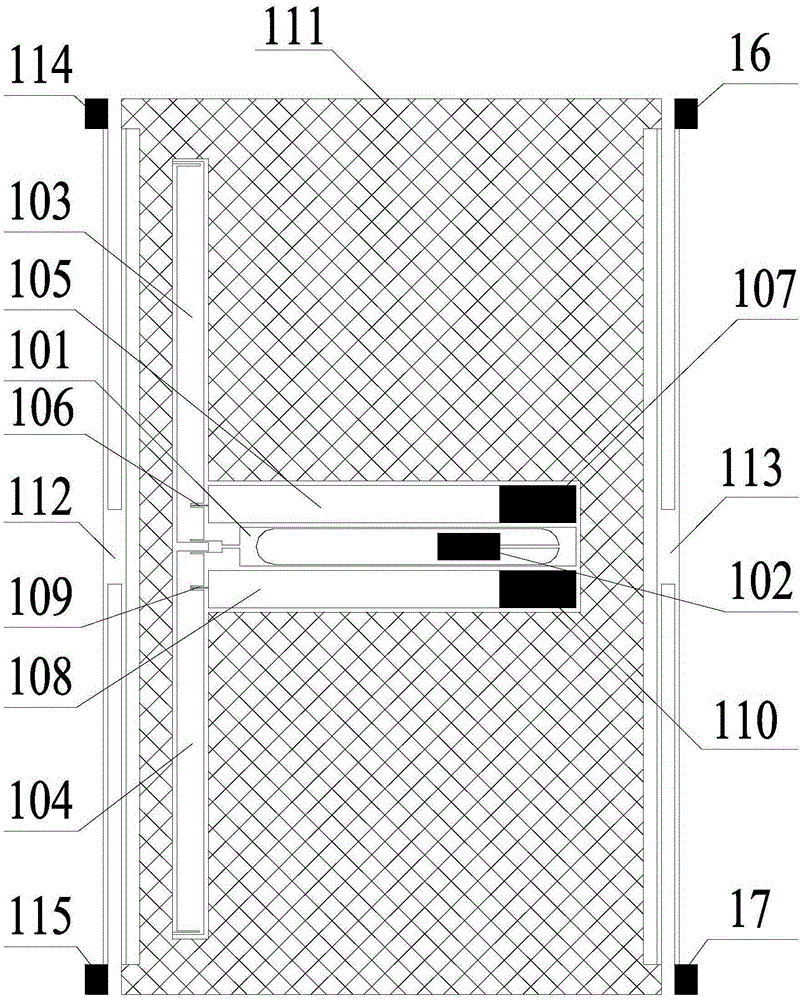

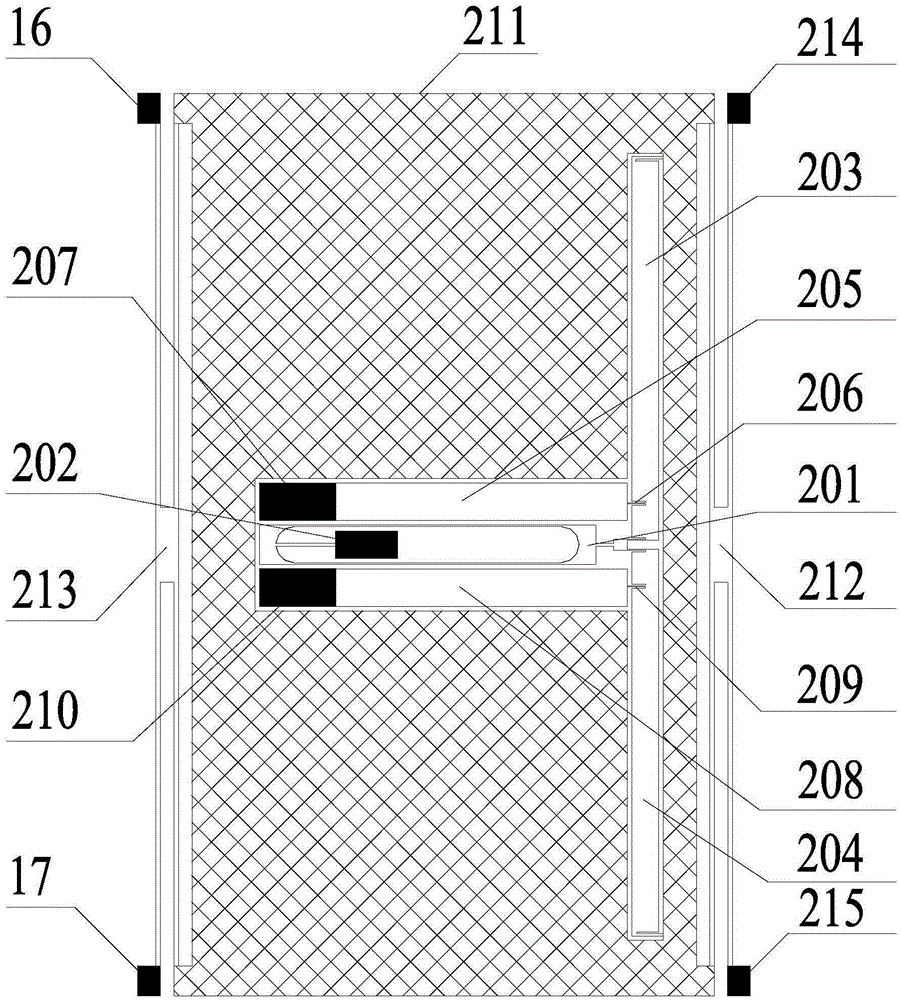

[0028] The basic idea of the present invention is: a silicon microresonance accelerometer with temperature stress compensation and vibration decoupling capability, the structure is two parts A and B that are independent of each other and symmetrical about the center line, and the two parts realize differential measurement. The mass blocks of each part are suspended in the air through their respective mass block support beams, which feel the acceleration input and generate acceleration inertia force. The acceleration inertial force is amplified by the force amplification of the lever, and applied to the axial direction of the tuning fork, which is converted into an axial force of the tuning fork, which changes the equivalent stiffness of the working vibration mode of the tuning fork, and the vibration frequency of the tuning fork changes accordingly. By detecting the resonance of the tuning fork The change of frequency can demodulate the magnitude of the acceleration load. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com