Ferrous sulfate heptahydrate drying system

A technology of ferrous sulfate and drying system, which is applied in the direction of ferric sulfate, drying, drying machine, etc. It can solve the problems of flash drying, sharp drop in drying performance, and sticking to the cylinder wall, etc., and achieve continuous production , the effect of smooth drying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

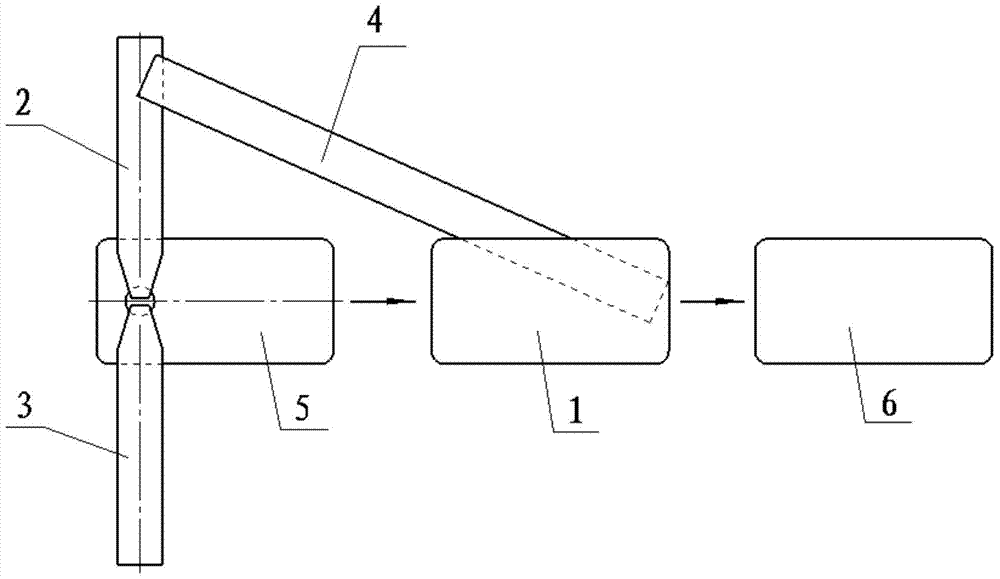

[0031] Ferrous sulfate heptahydrate drying system includes ferrous sulfate heptahydrate conveying device 3, first dry material conveying device 2, mixer 5 and first drying device 1, ferrous sulfate heptahydrate conveying device 3 and first dry The material conveying device 2 conveys materials to the mixer 5 respectively, and the materials discharged from the mixer 5 enter the first drying device 1;

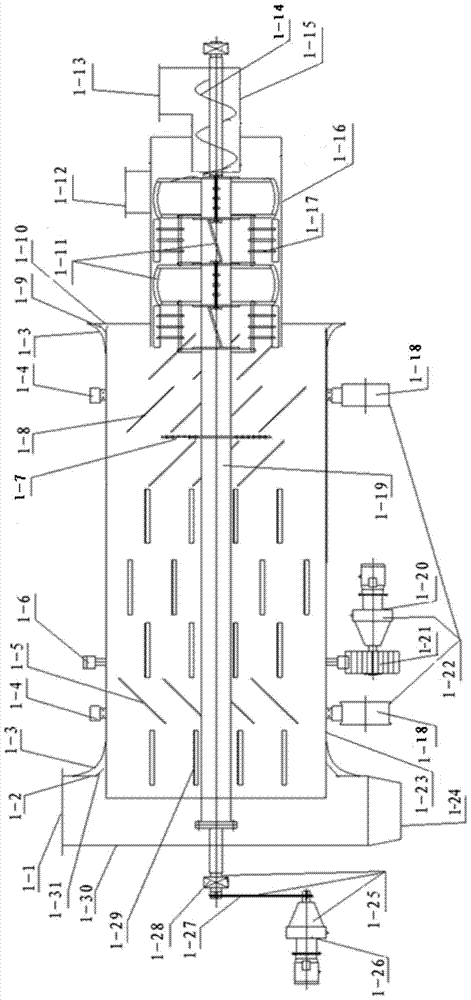

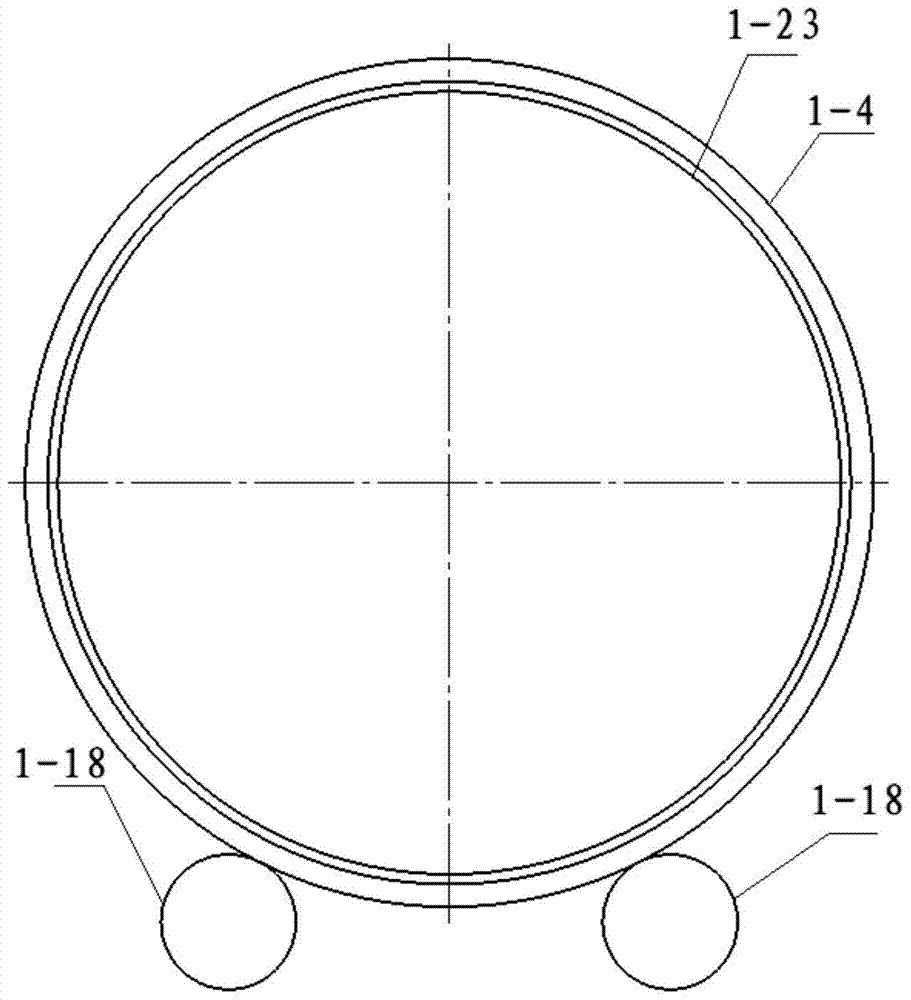

[0032] The first drying device 1 includes a feeding mechanism 1-15, a fixed drying cylinder 1-16, a rotating drying cylinder 1-23, a discharge mechanism 1-30, a central shaft 1-19, and a rotating drying cylinder supporting drive mechanism 1-22 and central shaft support drive mechanism 1-25;

[0033] The feeding mechanism 1-15, the fixed drying cylinder 1-16, the rotating drying cylinder 1-23 and the discharging mechanism 1-30 are arranged in seque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com