Electric transmission system of dual-power metro grinding car and power switching method

A technology of electric transmission and dual power, which is applied in the field of power transmission system of rail transit construction machinery vehicles, can solve the problems of affecting the subway space environment, unfavorable exhaust gas dissipation, inconvenient maintenance, etc., and achieve clear layout, flexible and convenient switching, and convenient maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

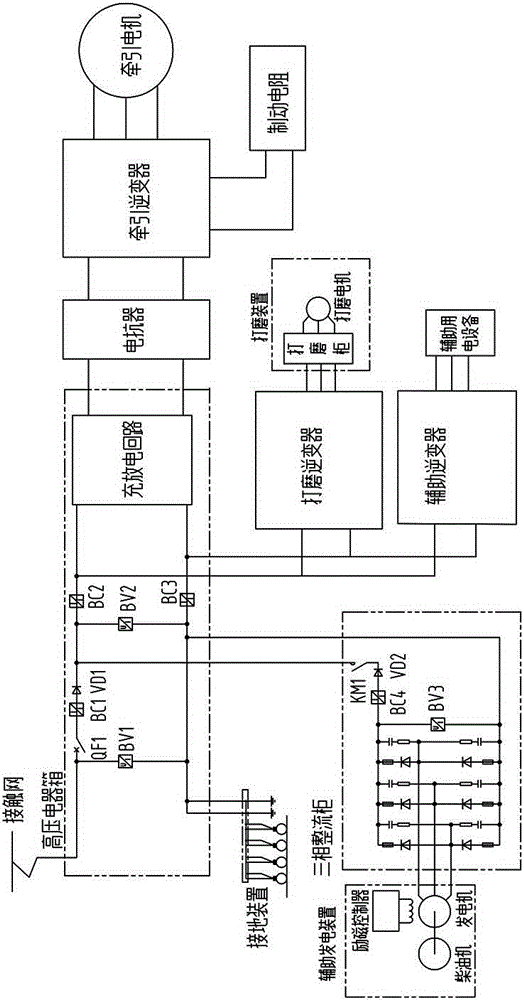

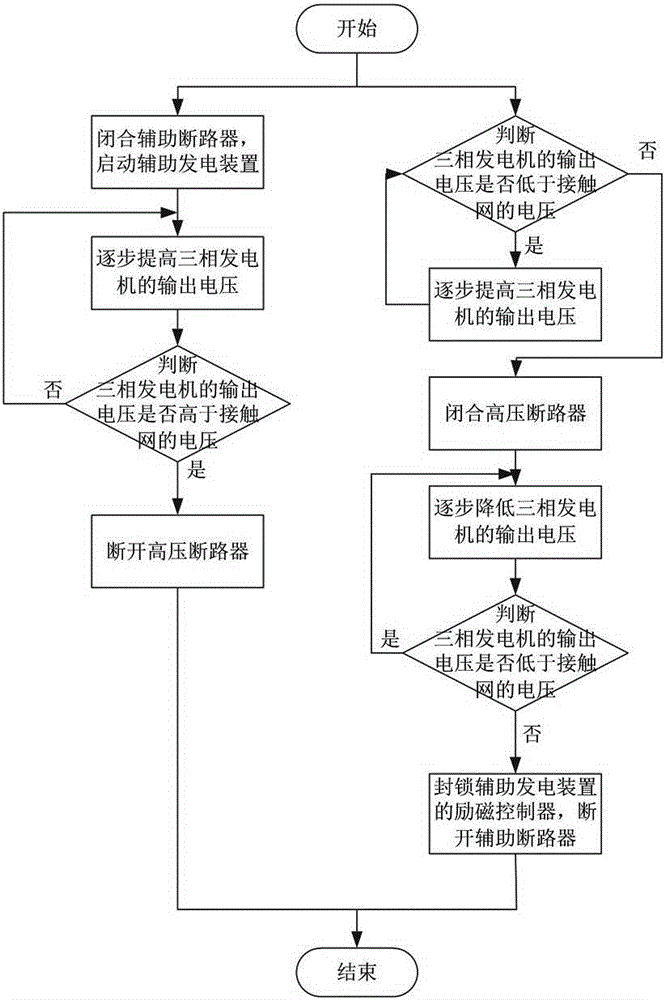

[0032] The dual-power grinding vehicle is composed of two fixed sections, the front vehicle is a tractor, the rear vehicle is a grinding vehicle, and the electric drive system is installed on the front vehicle. Such as figure 1 As shown, the electrical transmission system of a dual-power subway grinding car of the present invention includes a high-voltage electrical box, a reactor, a traction inverter, a traction motor, an auxiliary power generation device, a three-phase rectifier cabinet, a grinding inverter and a grinding device; The positive pole of the high-voltage busbar of the electrical box is connected to the catenary through the high-voltage circuit breaker QF1, the negative pole of the high-voltage busbar is grounded, and the output terminal of the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com