Valve side linearly coupled double-bridge shaft-type pressed rectifying device

A rectifier and straight row technology, which is applied to output power conversion devices, bus/circuit layout, electrical components, etc., can solve the problems of difficult installation, low safety, and reduced current sharing coefficient, and achieve improved maintenance safety, The effect of simple busbar layout and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

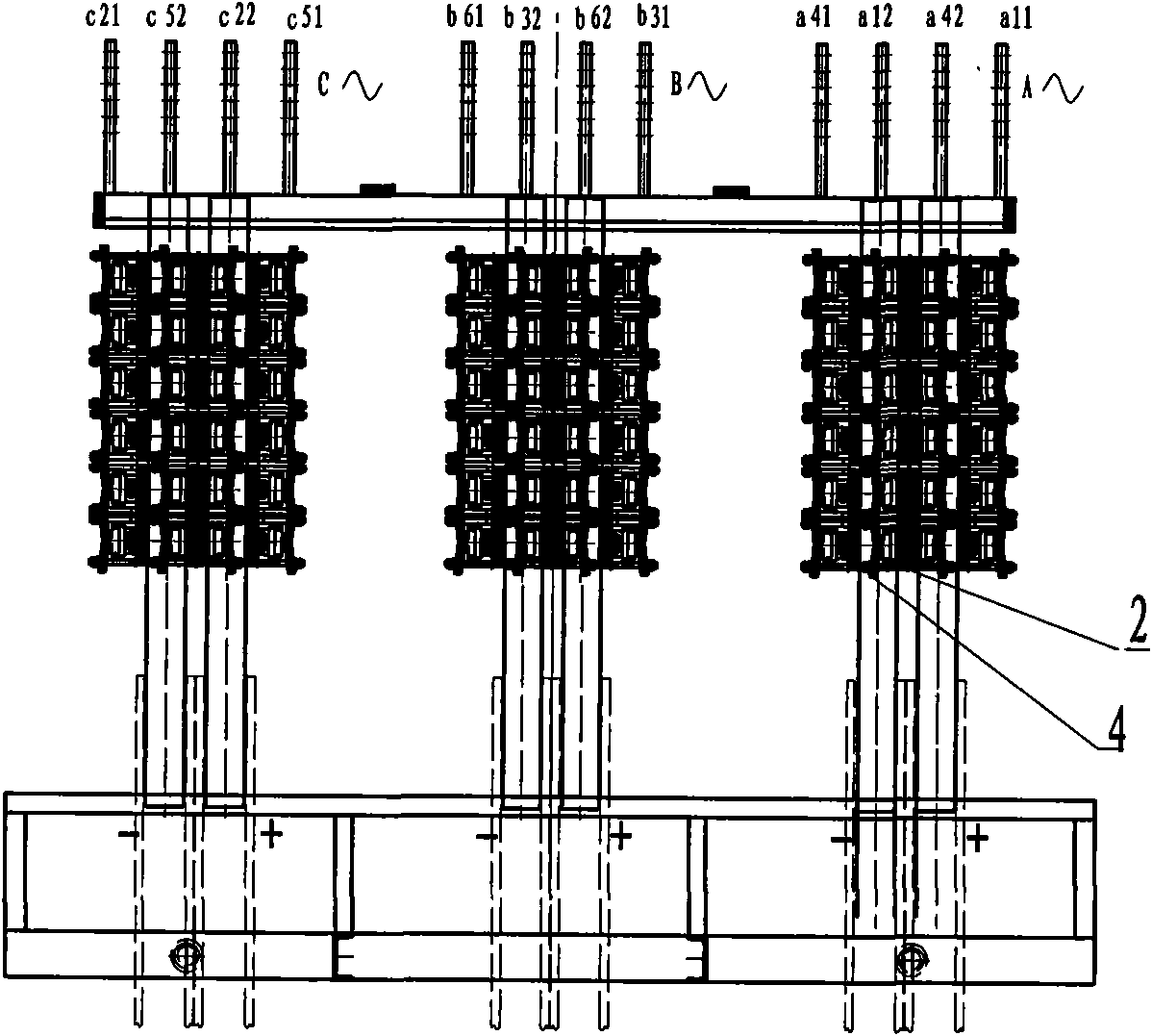

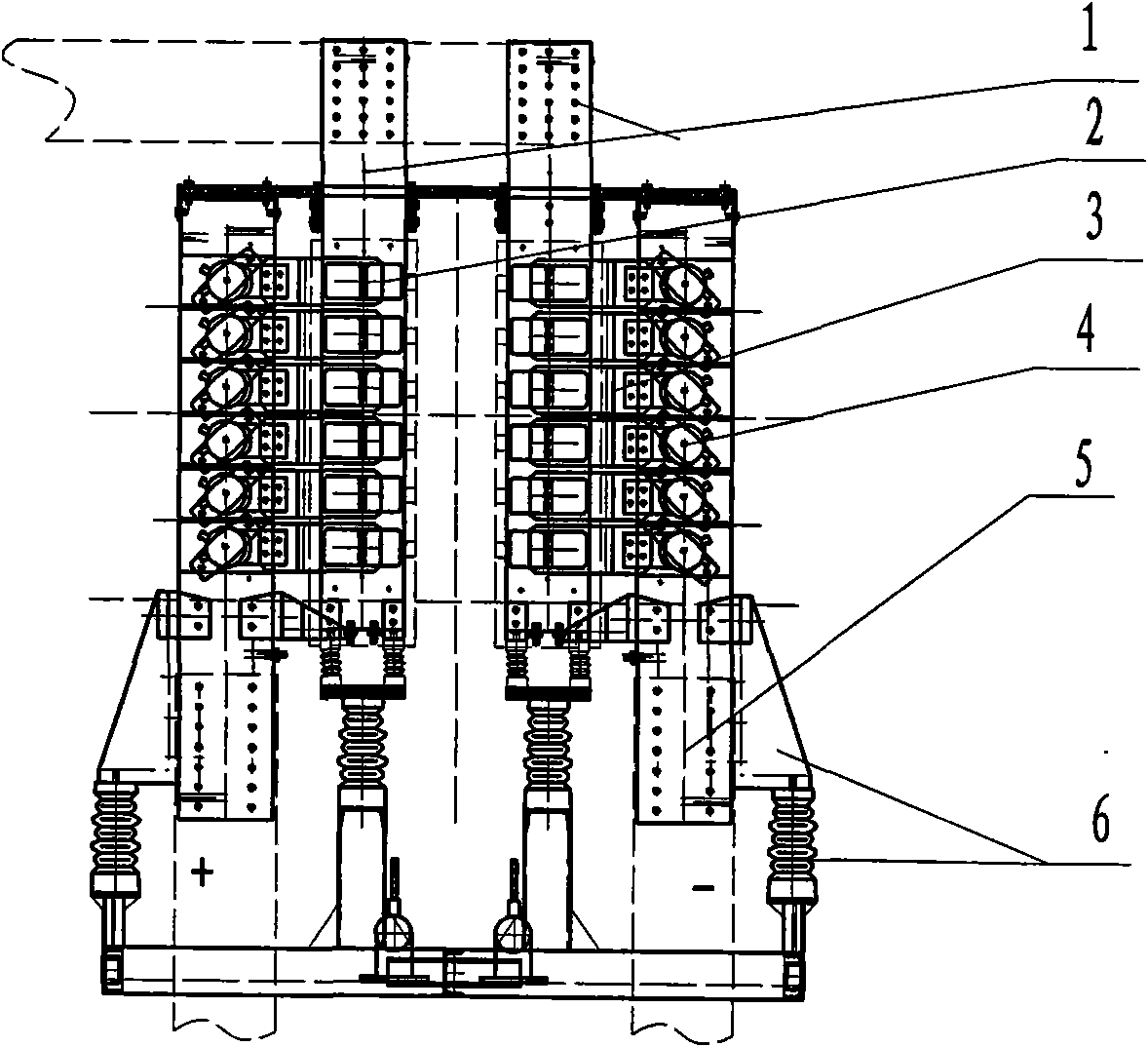

[0031] see figure 1 , figure 2 , image 3 , the present invention consists of a fast-melting busbar double-hole water-cooled bus 1 (three-phase bridge AC incoming line), a fast fuse 2, a connecting bus 3, a rectifier element 4, a component bridge arm porous water-cooled bus 5 (DC outgoing line), and a support member 6 In terms of configuration, the above-mentioned rectifying element 4 is installed symmetrically on the busbar of the bridge arm, that is, the components are installed symmetrically on both sides with the porous water-cooled busbar 5 of the bridge arm as the axis. The impedance of each branch circuit element is the same, and the force is the same, so the problem of the decrease of the current sharing coefficient caused by the arrangement of the elements is avoided to a certain extent. The problem of current equalization can be solved structurally, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com