Novel halogen-free and environment-friendly fire retardant and finishing method of novel halogen-free and environment-friendly fire retardant for textiles

A kind of flame retardant, environmental protection technology, applied in the field of halogen-free environmental protection flame retardant and its finishing of fabrics, to achieve good marketing value, improve flame retardant effect, high ecological and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

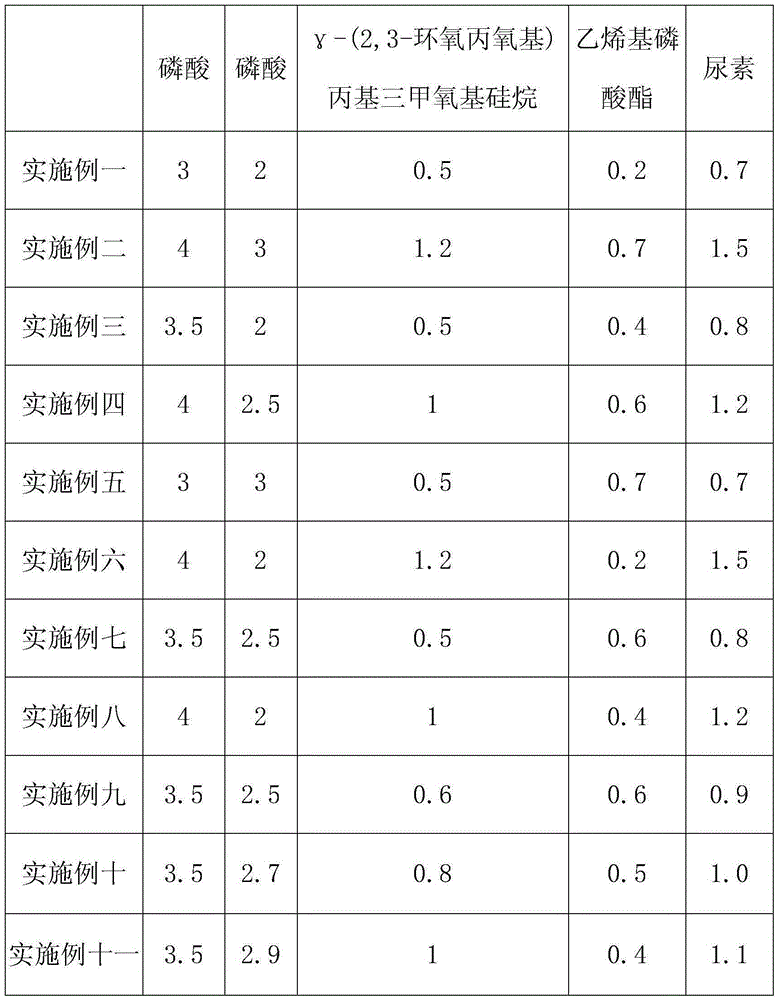

[0038] Embodiment: each component of the embodiment product of the present invention is shown in Table 1.

[0039] Table 1: The composition of each component of the halogen-free environmentally friendly flame retardant (unit: parts by weight)

[0040]

[0041] Described phosphoric acid is analytically pure;

[0042] The ethanol is dehydrated alcohol, analytically pure;

[0043] The γ-(2,3-glycidoxy)propyltrimethoxysilane is purchased from Aladdin Reagent Shanghai Co., Ltd., and the active ingredient content is ≥98%;

[0044] The vinyl phosphate is analytically pure;

[0045] The urea is analytically pure.

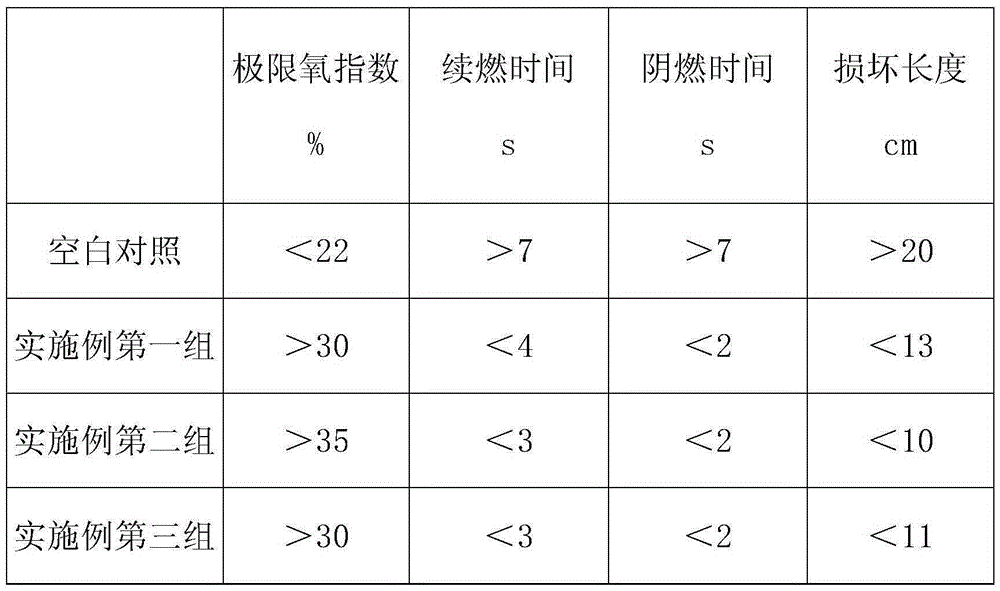

[0046] The finishing method of the fabric in the embodiment of the present invention includes preparation of working liquid, double dipping and rolling, first drying, baking, water washing, and second drying process; it is divided into three groups according to the different technological parameters of the finishing process:

[0047] First group:

[0048] The proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com