Floating-bead-free low-density oil well cement paste

An oil well cement slurry and oil well cement technology, which is applied in the field of oil and gas well cementing, can solve the problems of high price of nano wollastonite, and achieve the effects of stable density, small API filtration loss and improving cementing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

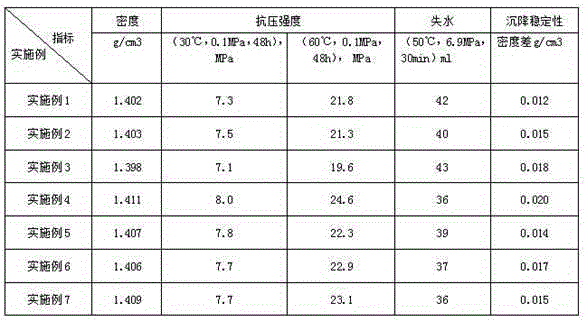

Examples

Embodiment 1

[0032] A kind of floating bead-free oil well cement slurry, including the following raw materials by mass percentage: ordinary portland cement 18%, superfine portland cement 30%, fly ash 22.5%, micro silicon 22%, triethanolamine 3.8% , fluid loss reducer QS12S2.5%, dispersant SXY1.2%.

Embodiment 2

[0034] A kind of oil well cement slurry without drift beads, comprising the following raw materials in terms of mass percentage: 10% of G grade oil well cement, 41.5% of superfine portland cement, 24% of micro silicon, 18% of diatomite, and 4.0% of calcium chloride , fluid loss reducer QS12S1.0%, dispersant SXY1.5%.

Embodiment 3

[0036] A kind of oil well cement slurry without bleaching beads, comprising the following raw materials by mass percentage: 15% of D grade oil well cement, 35% of superfine Portland cement, 20.5% of fly ash, 22% of bentonite, 2% of triethanolamine, chlorine Calcium 2%, fluid loss reducer G60S 3.0%, dispersant QS20S 0.5%.

[0037] The specific surface area of the superfine portland cement of the present embodiment is 1200cm 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com