Method for preparation of antifouling paint from synthetic hydroxyl terminated polyester copolymer

A technology of hydroxyl-terminated polyester and hydroxyl-terminated polyester, which is applied in the field of chemical materials, can solve the problems of high cost of synthetic resin, undisclosed resin degradation rate, and anti-fouling coating without shallow sea hanging board effect, so as to increase mechanical elasticity , good effect of antifouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

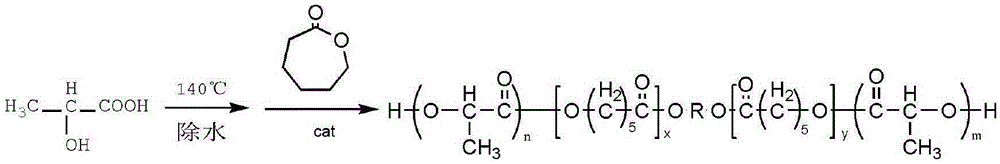

[0019] The invention is a method for preparing antifouling paint by synthesizing hydroxyl-terminated polyester copolymer.

[0020] The method of the present invention is divided into two steps. In the first step, lactic acid and lactone are used as comonomers, polyhydric alcohols are used as initiators, and toluenesulfonic acid and stannous octoate are used as catalysts to synthesize hydroxyl-terminated polysaccharides by melt polymerization. ester copolymer. For the preparation of the second step antifouling paint, the two steps are subject to the described technical scheme, and will not be described in detail.

[0021] The synthetic reference route of the hydroxyl-terminated polyester copolymer in the first step is as follows:

[0022]

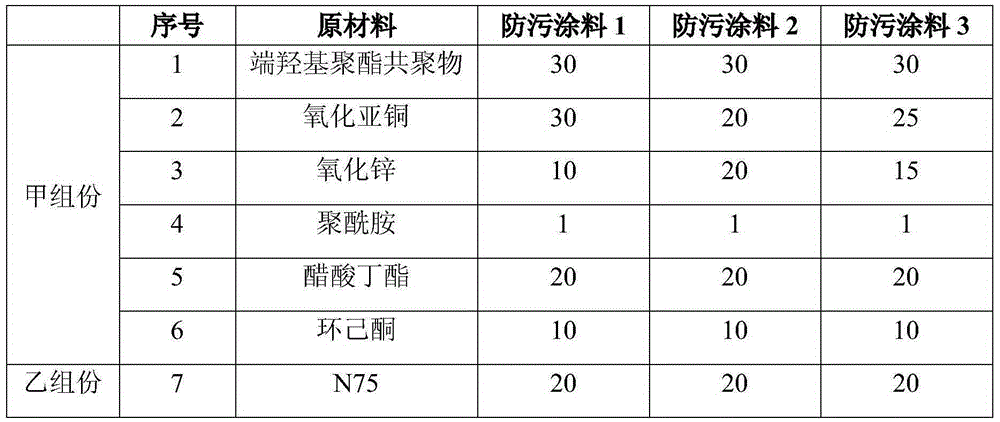

[0023] The present invention can be explained in more detail through the following three examples, the present invention is not limited thereto, and the purpose of disclosing the present invention is to protect all changes and improvemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com