A tension holding structure, tension holding device and vibrating wire equipment

A tension and protective sleeve technology, applied in the field of tension retention device, tension retention structure, and vibrating wire equipment, can solve the problems of small actual tension and reduced tension of the string, so as to improve stability, maintain stable tension, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

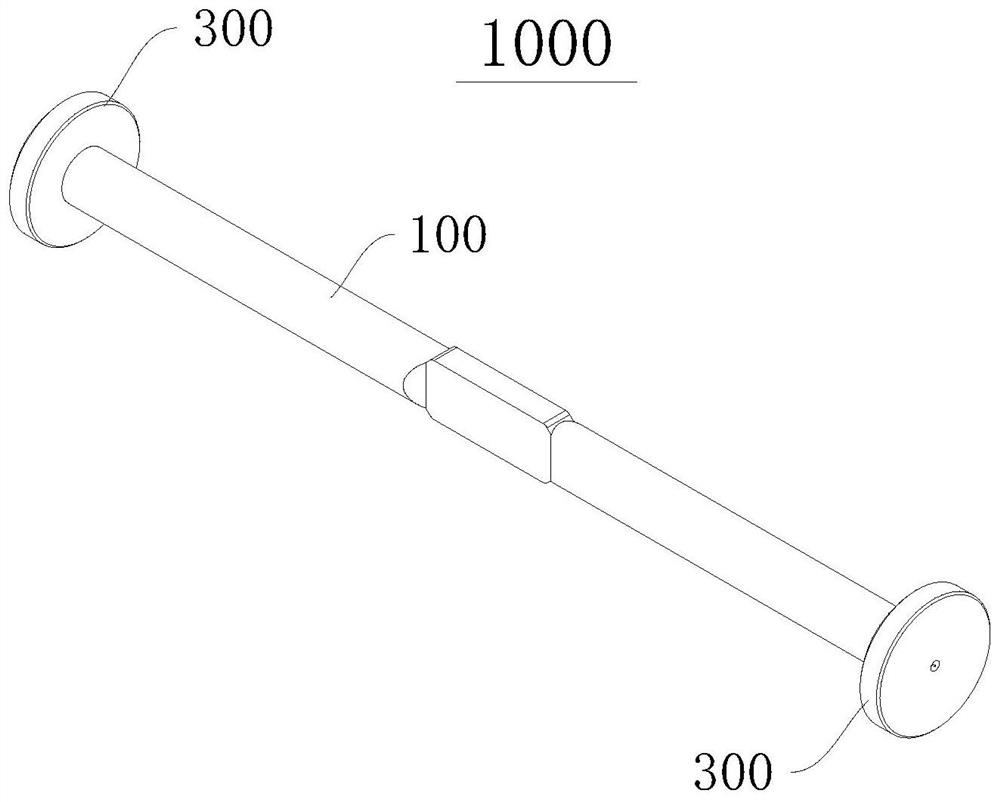

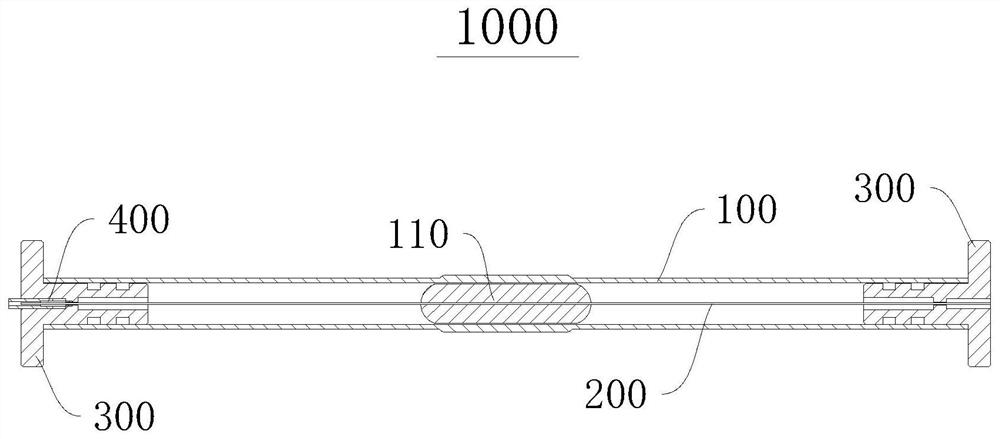

[0061] Please refer to figure 1 and figure 2 , this embodiment provides a tension holding device 1000, which is suitable for vibrating wire equipment, tension piles, etc., which can keep the tension of the tension string 200 passing through the above equipment stable.

[0062] The tension holding device 1000 includes: a protective cover 100 , a base 300 and a fixing assembly 400 . Both ends of the protective cover 100 are fitted with a base 300 , and the string 200 can be accommodated in the protective cover 100 and pass through the base 300 . The fixing assembly 400 fixes the pulling string 200 to the base 300 so that the pulling force of the pulling string 200 remains unchanged.

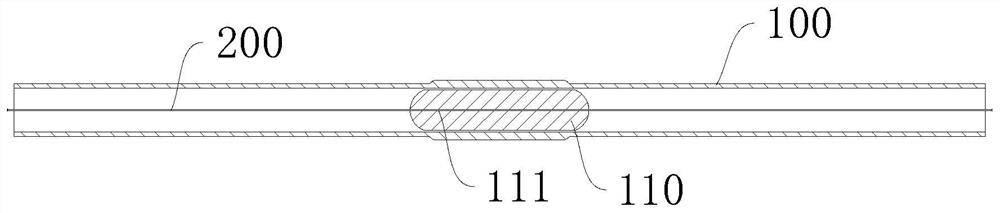

[0063] Please refer to image 3 , the protective sleeve 100 is in the shape of a cylinder as a whole, and the inner cavity of the protective sleeve 100 is a hollow pipe that penetrates the protective sleeve 100 along the axial direction thereof. The pull string 200 is accommodated in the inner...

Embodiment 2

[0116] Please refer to Figure 16 , and combine Figure 15 , This embodiment provides a vibrating wire device 2000 , and the vibrating wire device 2000 includes a pulling wire 200 , an electromagnetic component (not shown) and a tension holding device 1000 .

[0117] The pulling string 200 of the vibrating wire device 2000 is fixed by the pulling force holding device 1000. The pulling string 200 is arranged in the protective cover 100. 410 and reinforcement 420 are fixed.

[0118] The electromagnetic components are installed in the hollow pipe of the protective cover to detect the change of the vibration frequency of the pulling string 200 .

[0119] The vibrating wire device 2000 uses the tension holding device 1000 to fix the pulling string, and the pulling force of the pulling string remains unchanged at the initial preset value, which greatly improves the accuracy of measurement and induction, and has more stable, reliable performance and higher accuracy.

[0120] It ca...

Embodiment 3

[0122] Please refer to Figure 17 , this embodiment provides a tensile force holding structure 3000 , and the tensile force holding structure 3000 includes the base 300 , the connecting member 410 and the reinforcing member 420 of the tensile force holding device 1000 in the first embodiment.

[0123] The base 300 can be used to connect with other objects, such as being mounted on a concrete pile. In this case, when the base 300 is matched with the fixing assembly 400, one end of the pulling string 200 can be fixed, and the other end of the pulling string 200 can be fixed. It can be used to connect with other objects that need to be tensioned, and the tension retention structure 3000 can continuously provide stable tension to other objects.

[0124] The tension retaining structure 3000 can be applied to tension and reinforce electric piles, and can be used to tension electric wires, but is not limited thereto.

[0125] Please refer to Figure 18 , in a variation of this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com