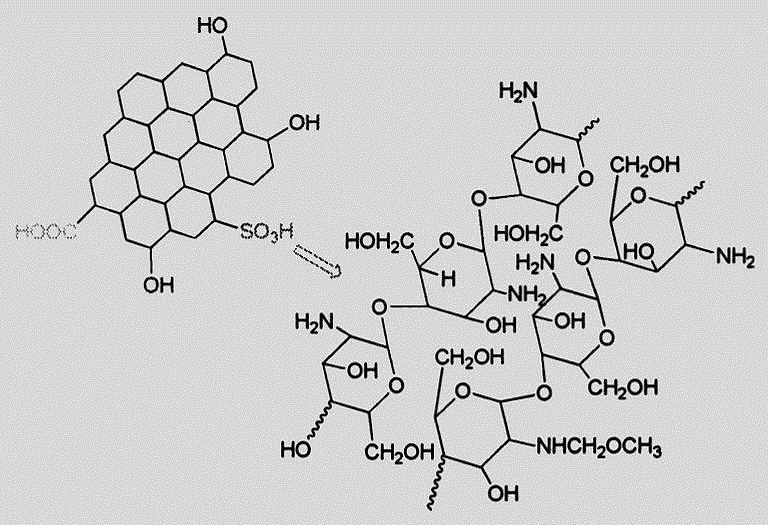

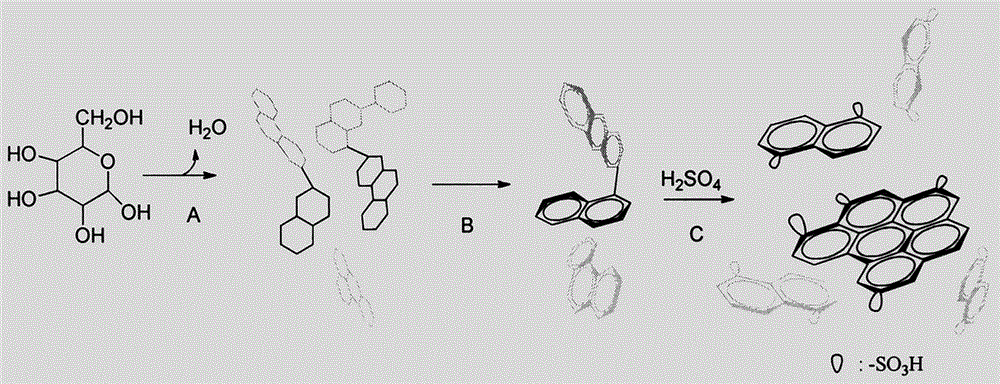

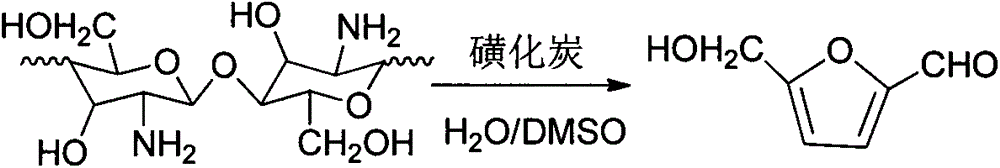

Degradation of chitosan/chitin with sulfonated carbon solid acid into high value 5-hydroxymethyl furfural

A technology of hydroxymethyl furfural and chitosan, applied in the direction of organic chemistry and the like, can solve the problems of difficult combination of process control and cost control, high production cost and application of 5-hydroxymethyl furfural, and achieve stable structure and post-processing. Simple and effective in reducing waste water generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] Example 1 Add 50mg chitosan to 50ml polytetrafluoroethylene lining, 250mg sulfonated carbon solid acid MC-SO 3 H, 2g of dimethyl sulfoxide and 10g of distilled water, then add the rotor, put it into a stainless steel reaction kettle and tighten it. Put it in a heat-collecting magnetic stirrer at a constant temperature of 180° C. for 4 hours. Immediately after the reaction time was up, it was quenched in an ice-water bath. After filtering the residue, a golden yellow aqueous solution was obtained, and then 1ml of the reaction solution was put into a small beaker, and 3g of methanol was added for dilution. Then it was filtered through a 0.22 μm nylon filter, and 2 μl of the diluted solution was injected into HPLC. The 5-hydroxymethylfurfural yield was calculated according to the 5-hydroxymethylfurfural marking line. The aqueous layer was extracted with 3×10 ml of ethyl acetate, and concentrated under reduced pressure to obtain relatively pure 5-hydroxymethylfurfural. ...

example 2

[0024] Example 2 Add 150mg chitosan 300mg sulfonated carbon solid acid MC-SO to 50ml polytetrafluoroethylene lining 3 H, 8g of dimethyl sulfoxide and 16g of distilled water, then add the rotor, put it into a stainless steel reaction kettle and tighten it. Put it in a heat-collecting magnetic stirrer at a constant temperature of 180° C. for 5 hours. Immediately after the reaction time was up, it was quenched in an ice-water bath. After filtering the residue, a golden yellow aqueous solution was obtained, and then 1ml of the reaction solution was put into a small beaker, and 3g of methanol was added for dilution. Then it was filtered through a 0.22 μm nylon filter, and 2 μl of the diluted solution was injected into HPLC. The 5-hydroxymethylfurfural yield was calculated according to the 5-hydroxymethylfurfural marking line. The aqueous layer was extracted with 3×10 ml of ethyl acetate, and concentrated under reduced pressure to obtain relatively pure 5-hydroxymethylfurfural. ...

Embodiment 3

[0025] Example 3 Add 100mg chitin and 500mg sulfonated carbon solid acid MC-SO to 50ml polytetrafluoroethylene lining 3 H, 4g of dimethyl sulfoxide and 20g of distilled water, then add the rotor, put it into a stainless steel reaction kettle and tighten it. Put it in a heat-collecting magnetic stirrer at 200° C. for 0.5 hours. Immediately after the reaction time was up, it was quenched in an ice-water bath. After filtering the residue, a golden yellow aqueous solution was obtained, and then 1ml of the reaction solution was put into a small beaker, and 3g of methanol was added for dilution. Then it was filtered through a 0.22 μm nylon filter, and 2 μl of the diluted solution was injected into HPLC. The 5-hydroxymethylfurfural yield was calculated according to the 5-hydroxymethylfurfural marking line. The aqueous layer was extracted with 3×10 ml of ethyl acetate, and concentrated under reduced pressure to obtain relatively pure 5-hydroxymethylfurfural. The highest yield of 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com