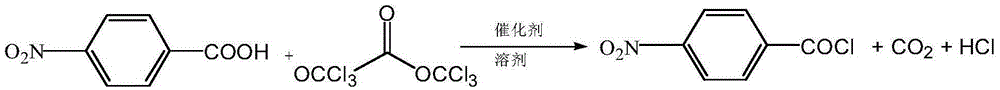

Synthesis method of paranitrobenzoyl chloride

A technology of nitrobenzoyl chloride and a synthetic method, which is applied in the field of organic synthesis, can solve problems such as not occurring, and achieve the effects of saving equipment costs, high yield, and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Take 3.0 moles of p-nitrobenzoic acid and 100 ml of dry toluene solution in a three-necked flask equipped with a reflux condenser, drop a small amount of dry pyridine as a catalyst, add 0.5 moles of triphosgene, and place the entire device in a 40-degree oil bath Magnetic stirring was carried out in the pot for 5 hours, the reaction by-product hydrogen chloride gas was drawn out with a reflux condenser, absorbed with lye, the crude product was distilled off under reduced pressure to remove the solvent, and the calculated yield was 95.89%;

Embodiment 2

[0018] Take 1.0 mole of p-nitrobenzoic acid and 100 ml of dry dichloromethane solution in a three-necked flask equipped with a reflux condenser, drop a small amount of dry N,N-dimethylformamide as a catalyst, and add 0.8 mole of Sanko Gas, the whole device was placed in a 50-degree oil bath and stirred magnetically for 5 hours. The reaction by-product hydrogen chloride gas was drawn out with a reflux condenser and absorbed with lye. The crude product was distilled under reduced pressure to remove the solvent, and the calculated yield was 97.65%;

Embodiment 3

[0020] Take 1.0 moles of p-nitrobenzoic acid and 100 milliliters of dry ethyl acetate solution and place it in a three-necked flask equipped with a reflux condenser, drop in trifluoroformic acid sulfonate with a mole fraction of 5% as a catalyst, and add 1.1 moles of Sanko The whole device was placed in a 60-degree oil bath with magnetic stirring for 12 hours. The reaction by-product hydrogen chloride gas was drawn out with a reflux condenser and absorbed with lye. The crude product was distilled under reduced pressure to remove the solvent. The calculated yield was 98.49%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com