Reduction processing device and method for residual activated sludge

A technology of residual activity and treatment device, applied in sludge treatment, biological sludge treatment, etc., can solve the problems of slow degradation rate of biological sludge, high dissolved oxygen, long reaction time, etc., to increase transfer utilization efficiency, fast and efficient The effect of separating and improving the degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

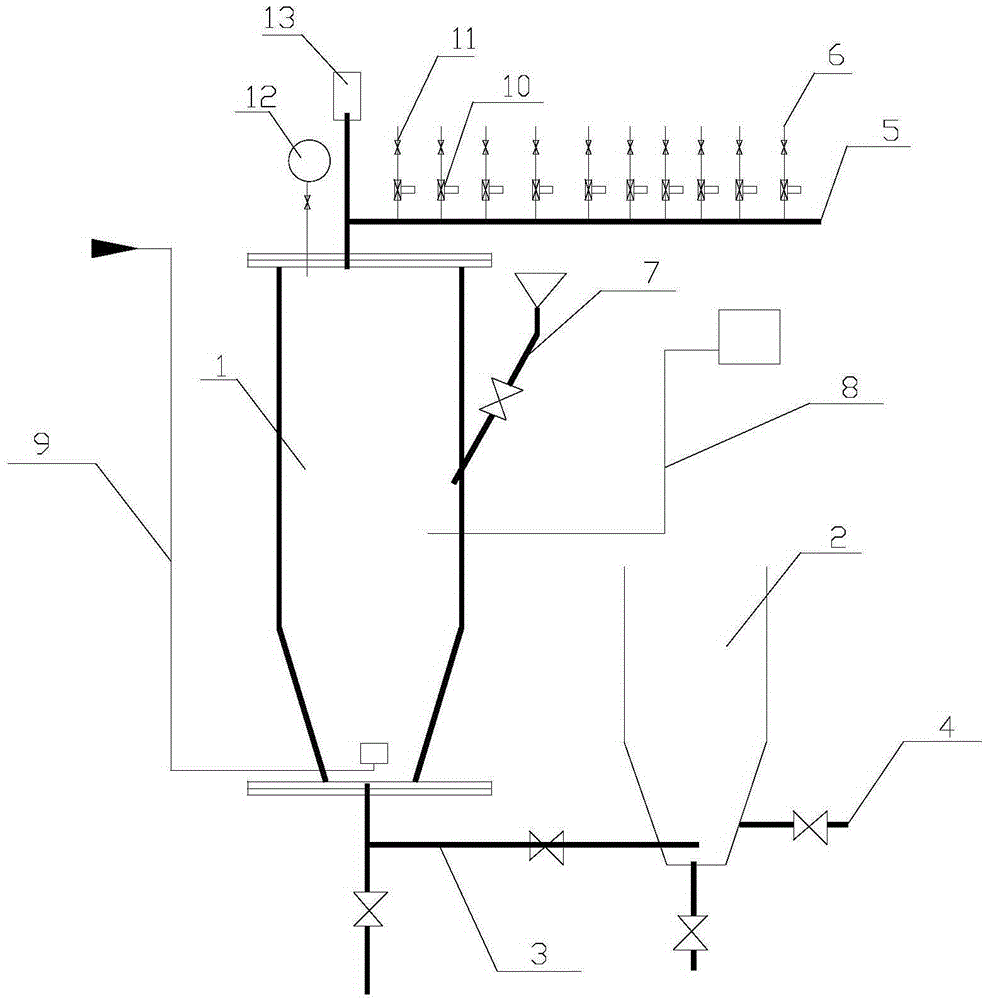

[0021] A reduction treatment device for excess activated sludge, the device includes a high-pressure bioreactor 1 and a floating separator 2, the bottom of the high-pressure bioreactor 1 communicates with the bottom of the floating separator 2 through a sample outlet pipe 3; the floating separator 2 A clarified water discharge pipe 4 is provided under one side; an exhaust main pipe 5 is provided on the top of the high-pressure bioreactor 1, and an exhaust branch pipe 6 is provided on the exhaust main pipe 5; Pipe 7, dosing pipe 8 and aeration air supply pipe 9.

[0022] The exhaust main pipe 5 is provided with 10 exhaust branch pipes 6; each exhaust branch pipe 6 is provided with a solenoid valve 10 and a manual valve 11.

[0023] The top of the high-pressure bioreactor 1 is provided with a pressure gauge 12 and an adjustable pressure safety valve 13 .

[0024] Applying the above-mentioned device to carry out the method for the reduction treatment of excess activated sludge, ...

Embodiment 2

[0033] A reduction treatment device for excess activated sludge, the device includes a high-pressure bioreactor 1 and a floating separator 2, the bottom of the high-pressure bioreactor 1 communicates with the bottom of the floating separator 2 through a sample outlet pipe 3; the floating separator 2 A clarified water discharge pipe 4 is provided under one side; an exhaust main pipe 5 is provided on the top of the high-pressure bioreactor 1, and an exhaust branch pipe 6 is provided on the exhaust main pipe 5; Pipe 7, dosing pipe 8 and aeration air supply pipe 9.

[0034] The exhaust main pipe 5 is provided with 10 exhaust branch pipes 6; each exhaust branch pipe 6 is provided with a solenoid valve 10 and a manual valve 11.

[0035] The top of the high-pressure bioreactor 1 is provided with a pressure gauge 12 and an adjustable pressure safety valve 13 .

[0036] Applying the above-mentioned device to carry out the method for the reduction treatment of excess activated sludge, ...

Embodiment 3

[0045] A reduction treatment device for excess activated sludge, the device includes a high-pressure bioreactor 1 and a floating separator 2, the bottom of the high-pressure bioreactor 1 communicates with the bottom of the floating separator 2 through a sample outlet pipe 3; the floating separator 2 A clarified water discharge pipe 4 is provided under one side; an exhaust main pipe 5 is provided on the top of the high-pressure bioreactor 1, and an exhaust branch pipe 6 is provided on the exhaust main pipe 5; the high-pressure bioreactor 1 is sequentially provided with sampling Pipe 7, dosing pipe 8 and aeration air supply pipe 9.

[0046] The exhaust main pipe 5 is provided with 10 exhaust branch pipes 6; each exhaust branch pipe 6 is provided with a solenoid valve 10 and a manual valve 11.

[0047] The top of the high-pressure bioreactor 1 is provided with a pressure gauge 12 and an adjustable pressure safety valve 13 .

[0048] Applying the above-mentioned device to carry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com