Pneumatic type positioning device used for torsion beam punch forming

A stamping forming and positioning device technology, applied to positioning devices, forming tools, feeding devices, etc., can solve the problems of time-consuming and laborious positioning of parts, difficulty in distinguishing left and right directions, and increased labor intensity of workers, so as to achieve convenient positioning and identification of left and right directions Easy, small height effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

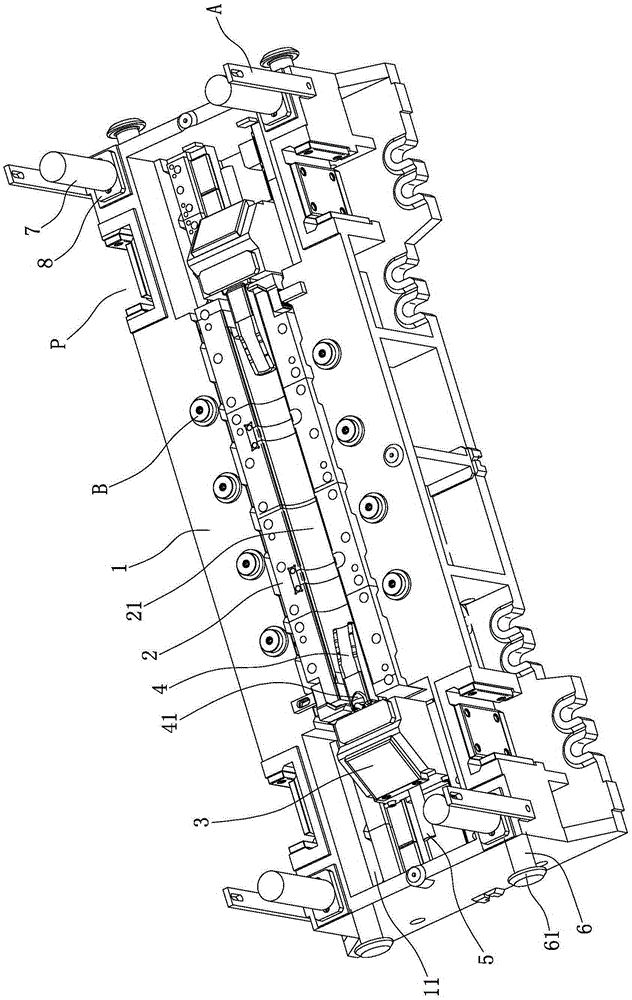

[0018] Such as figure 1 As shown, the mold base 1 is formed by casting. A group of lifting lugs 6 are respectively arranged on the left end surface and the right end surface of the mold base 1, and each group of lifting lugs 6 is divided into front and rear two, and four lifting lugs 6 are distributed in a rectangle on the same horizontal plane. The lifting lug 6 is a cylinder, one end of the lifting lug 6 is fixed to the mold base 1 , and the other end of the lifting lug 6 is integrally formed with an annular boss 61 . The four corners of the top surface of the mold base 1 are provided with uprights 7, the uprights 7 are cylinders, and the four uprights are distributed in a rectangle. Fixed connection.

[0019] Such as figure 1 As shown, a group of connection plates A are respectively arranged at the left and right ends of the mold base 1, and each group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com