Automatic balancing device for discharging outlet material receiving plates of parallel-connection mining crusher

An automatic balancing and receiving tray technology, which is applied in the field of coal mine machinery and equipment, can solve problems such as increasing the time for repairing damaged parts and maintaining equipment, affecting the production efficiency of the production line, and unbalanced materials on the conveyor belt, etc., achieving light weight, long service life, and lightening The effect of wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be further described (left-right direction and front-rear direction in the following description and figure 1 The left-right direction and the front-back direction in are the same, figure 1 The direction far away from the reader is the back, and the front and rear directions are the movement direction of the transmission belt).

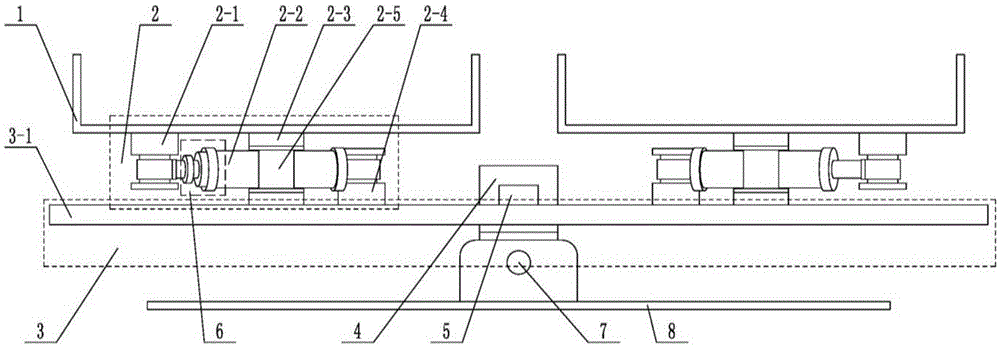

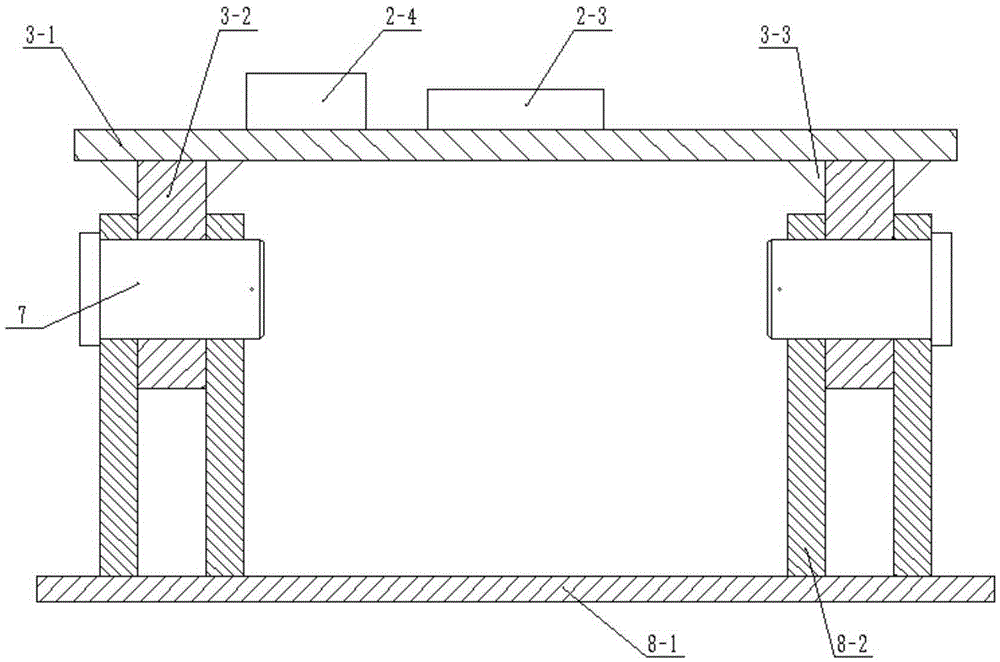

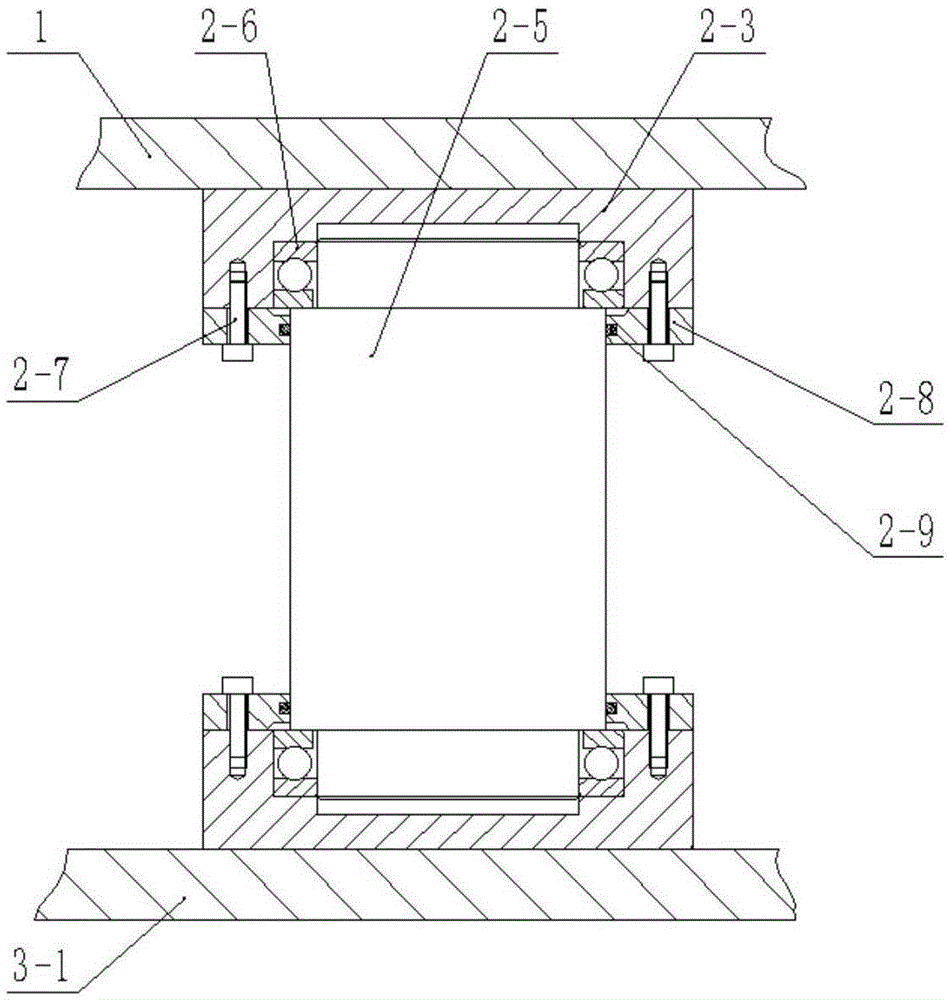

[0020] Such as figure 1 As shown, an automatic balancing device for the receiving tray of the discharge port of a parallel mine crusher, including a receiving tray 1, a hydraulic control device 2, a rotatable bottom plate device 3, an inclination sensor 4, a single-chip microcomputer 5, and a magnetostrictive displacement The sensor 6 and the support seat 8, the outlets of the two receiving trays 1 are inclined to the conveyor belt, and the two receiving trays 1 are respectively connected to the upper plane of the bottom plate 3-1 in the rotatable bottom plate device 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com