Forage pulverizer

A forage grinder and crushing chamber technology, applied in grain processing, etc., can solve problems such as poor crushing effect, achieve good crushing effect, improve utilization rate, increase or decrease the effect of hammer blades and air chambers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

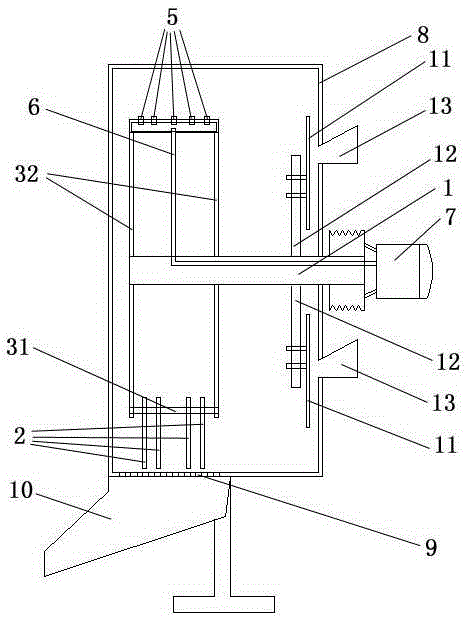

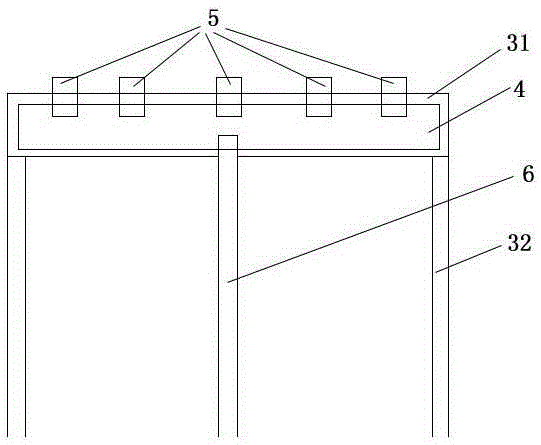

[0023] like Figure 1-2 As shown, the forage grinder provided in this embodiment includes a rotating shaft 1, a hammer 2, a hammer frame, an air cavity 4, an air nozzle 5, an air guide pipe 6, a blower 7 and a crushing chamber 8, and the rotating shaft 1 Penetrating into the crushing chamber 8 from the outside, the hammer frame is arranged on the rotating shaft 1 in the crushing chamber 8; the hammer frame is provided with two mounting pieces 31, and the mounting pieces 31 are parallel to the rotating shaft 1 axis One mounting piece 31 is provided with an air cavity 4, the outer end surface of the mounting piece 31 with the air cavity 4 is provided with an air nozzle 5, and the other mounting piece 31 is provided with a hammer perpendicular to the axial direction of the rotating shaft 1. Sheet 2; the air nozzle 5 communicates with the air chamber 4; the air chamber 4 communicates with the blower 7 arranged outside the crushing chamber 8 through the air duct 6; the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com