Fragrance type heating nonflammable tobacco product and preparation method thereof

A heat-not-burn and tobacco product technology, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment, can solve the problems of tobacco extracts without fine segmentation, weak tobacco aroma, and low aroma concentration, and achieve rich wine body Full-bodied, long aftertaste, outstanding effect of smoke fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

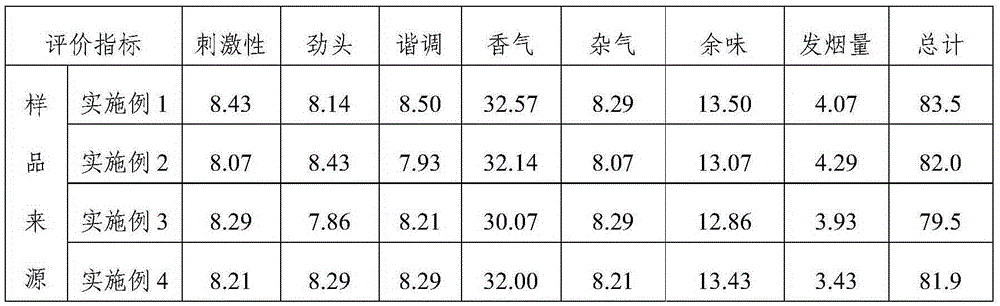

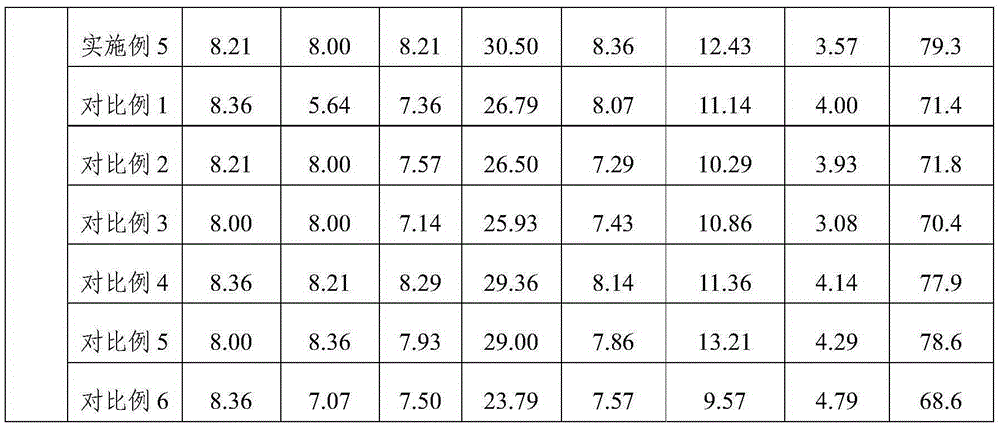

Embodiment 1

[0033] A fragrant heat-not-burn tobacco product prepared from the following raw materials: 3kg fragrant flue-cured tobacco extract, 2kg tobacco flavor, 1kg taste and flavor regulator, 3kg Fenjiu, 8kg glycerin, and 83kg fragrant flue-cured tobacco flakes;

[0034] The flue-cured tobacco extract is prepared by the following steps: take the flue-cured tobacco leaves prepared in the wine cellar, pulverize through a pulverizer and pass through a 40-60 mesh sieve, mix 1g / 3ml with ethanol uniformly, and ultrasonically at a frequency of 40kHz at 50°C After extraction for 4 hours, after standing and settling, it was filtered with sand core funnel and 0.45μm microporous membrane, and concentrated under reduced pressure at 70℃. The feed rate was 5ml / min, the vacuum was 18Pa, and the rotation speed was 350r / min. 1. Molecular distillation is carried out under the conditions of heating temperature 80℃ and cooling temperature 10℃ to obtain flue-cured tobacco essential oil, namely flue-cured toba...

Embodiment 2

[0039] A fragrant heat-not-burning tobacco product prepared from the following raw materials: 5.5kg of Burley tobacco extract, 3.5kg of tobacco flavor, 2kg of taste and flavor regulator, 1kg of Baofeng wine, 12kg of glycerin, and burley tobacco flakes 76kg;

[0040] The burley tobacco extract is prepared by the following steps: take the burley tobacco leaves prepared in the wine cellar, pass through a 40-60 mesh sieve after being crushed by a pulverizer, and mix 1g / 3ml with ethanol evenly at 45°C Ultrasonic extraction with a frequency of 30kHz for 4h, after standing and settling, followed by filtration with a sand core funnel and a 0.45μm microporous filter membrane, concentrated under reduced pressure at 70°C, at a feed rate of 8ml / min and a vacuum of 20Pa, Molecular distillation is carried out under the conditions of speed of 400r / min, heating temperature of 80°C, and cooling temperature of 10°C to obtain burley tobacco essential oil, that is, burley tobacco extract;

[0041] Th...

Embodiment 3

[0045] A fragrant heat-not-burn tobacco product prepared from the following raw materials: 1 kg of oriental tobacco extract, 2 kg of tobacco flavor, 0.5 kg of taste and flavor modifier, 4 kg of Kinmen sorghum, 5.5 kg of glycerin, and 87 kg of oriental tobacco expanded shredded tobacco;

[0046] The preparation method of the oriental tobacco extract is the same as in Example 1;

[0047] The tobacco flavor is uniformly mixed with the following components by weight percentage: macrostigmine 4%, ethyl maltol 3%, ethyl vanillin 0.5%, palmitic acid 0.5%, dihydrokiwifruit lactone 0.2 %, dimethyl succinate isovaleric acid 0.1%, β-ionone 0.5%, benzyl alcohol 0.2%, vanilla extract 2%, 4% ambergris and propylene glycol 85%;

[0048] The mouthfeel and fragrance modifier is uniformly mixed with the following ingredients in weight percentage: ethyl acetate 40.20%, ethyl lactate 24.90%, ethyl butyrate 0.04%, ethyl caproate 0.02%, ethyl caprylate 0.03%, 2 -Ethyl hydroxycaproate 0.08%, diethyl succi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com