A kind of manufacturing method of aluminum base circuit board

A technology of aluminum-based circuit boards and manufacturing methods, which is applied in the manufacture of printed circuits, the manufacture of printed circuit precursors, printed circuits, etc., can solve the problems of high product warpage, high molding pressure, and poor uniformity, and achieve improved heat dissipation performance , Ensure production safety and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

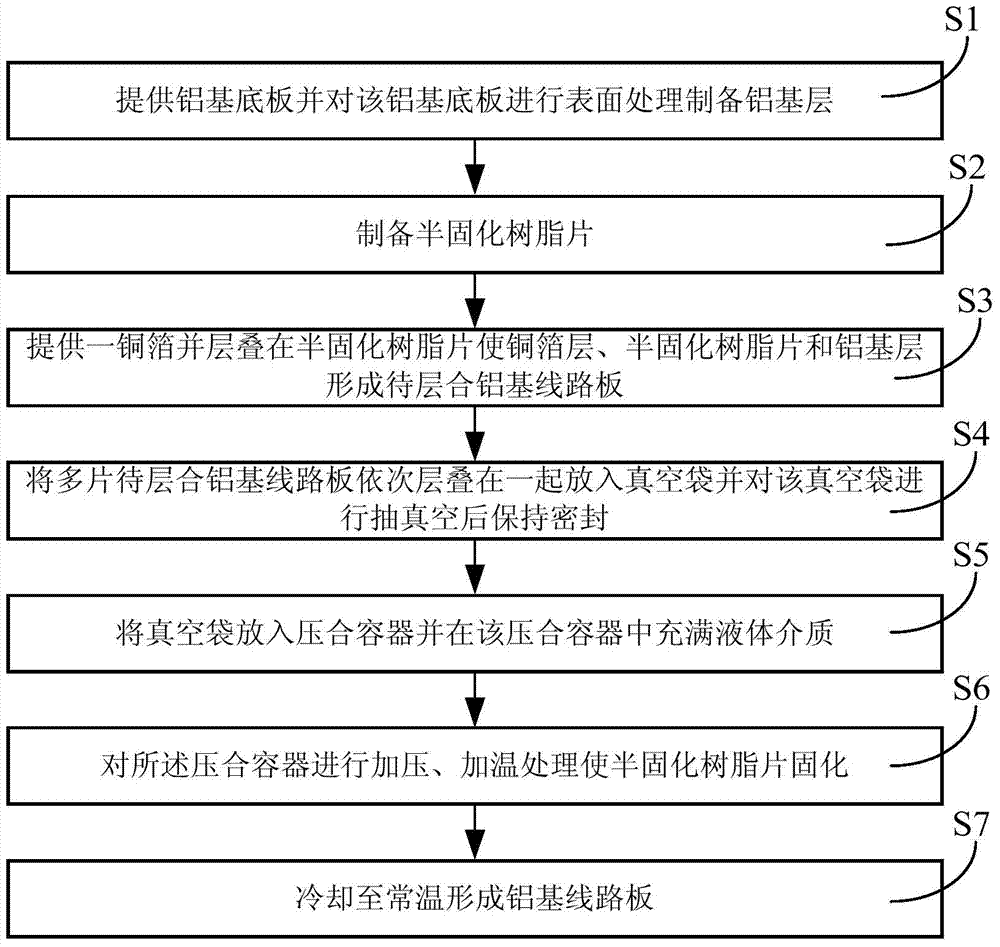

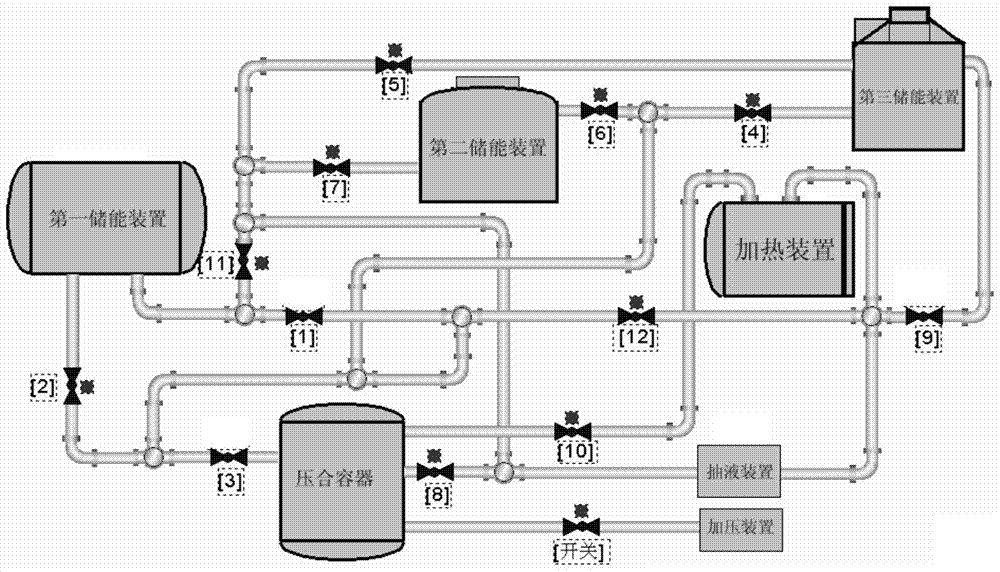

[0038] In order to overcome the shortcomings of the existing technology, please refer to figure 1 , which is a schematic flow chart of a method for manufacturing an aluminum-based circuit board provided in an embodiment of the present invention, a method for manufacturing an aluminum-based circuit board includes the following steps:

[0039] Step S1: providing an aluminum substrate, and performing surface treatment on the aluminum substrate to prepare an aluminum substrate;

[0040] Step S2: Prepare a semi-cured resin sheet, which is a composition composed of 65% to 85% of an epoxy resin mixture and 15% to 35% of a nano-inorganic filler; the epoxy resin mixture includes vitrified Epoxy resin, amino-terminated polyurethane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com