Novel lithium-pre-intercalated negative plate and preparation method thereof

A technology of pre-embedded lithium and negative electrode sheet, which is applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve the problem of low amount of pre-embedded lithium, achieve more pre-embedded lithium, good binding force, and improve distribution uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

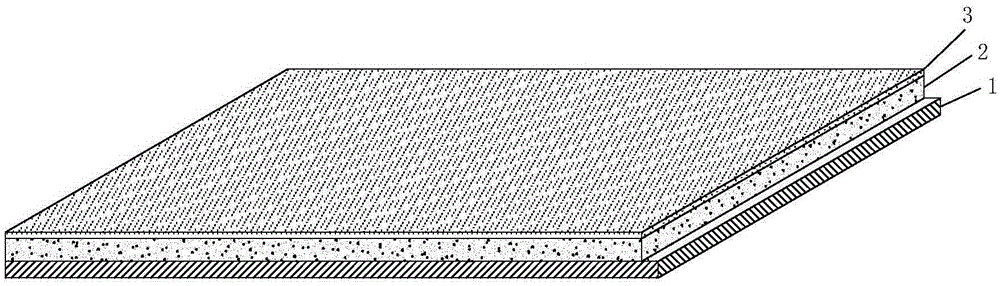

[0043] The structure of the pre-embedded lithium negative plate of the lithium ion capacitor of the present invention is as follows: figure 1 As shown, the current collector 1 including the porosity (the several through holes provided on the current collector 1 are not in the figure 1 Shown in the table), the current collector 1 is coated with a layer of active material layer 2, and the active material layer 2 is coated with a layer of pre-intercalated lithium layer 3.

[0044] The novel lithium pre-intercalated negative electrode sheet is prepared by the following method:

[0045] (1) Target material preparation: mix uniformly at a ratio of 50% by mass of graphite and 50% by mass of lithium titanate, press to make a 1mm thick target, and place it in the measurement and control sputtering Corresponding location of coating equipment.

[0046] Substrate preparation:

[0047] ①. Mix 80% graphite, 10% vapor-grown carbon fiber, and 10% polytetrafluoroethylene expressed in mass p...

Embodiment 2

[0058] The pre-intercalated lithium negative electrode sheet is prepared by the following method:

[0059] (1) Target material preparation: Mix uniformly with a mass percentage of graphite of 60% and a mass percentage of nickel-cobalt-lithium-manganese oxide of 40%, press to make a 3mm-thick target, and place it in the measurement and control Corresponding location of sputter coating equipment.

[0060] The preparation of the substrate was the same as that in Example 1, and the obtained substrate was cleaned and put into the cavity of the measurement and control sputtering coating equipment.

[0061] (2), the chamber is vacuumed to 5×10 -4 Pa;

[0062] (3), heating the substrate to a constant temperature of 60°C;

[0063] (4) Argon gas is introduced into the cavity, and the pressure is maintained at 2Pa;

[0064] (5) Turn on the cathode power supply of the magnetron sputtering coating equipment to perform sputtering coating.

[0065] The sputtering power of the magnetron ...

Embodiment 3

[0067] The pre-intercalated lithium negative electrode sheet is prepared by the following method:

[0068] (1) Preparation of the target material: 70% by mass of graphite, 30% by mass of a mixture of lithium iron phosphate and lithium manganate (mixed in a mass ratio of 1:1), uniformly mixed, and pressed. A target material with a thickness of 5 mm was made and placed in the corresponding position of the measurement and control sputtering coating equipment.

[0069] The preparation of the substrate was the same as that in Example 1, and the obtained substrate was cleaned and put into the cavity of the measurement and control sputtering coating equipment.

[0070] (2), the cavity is vacuumed to 10 -3 Pa;

[0071] (3), heating the substrate to a constant temperature of 120°C;

[0072] (4) Argon gas is introduced into the cavity, and the air pressure is maintained at 5Pa;

[0073] (5) Turn on the cathode power supply of the magnetron sputtering coating equipment to perform spu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com