Silicon carbide PiN device ohmic contact method

An ohmic contact, silicon carbide technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems affecting the performance of silicon carbide PiN devices, deterioration of N-type ohmic contact quality, etc., to achieve good ohmic contact characteristics, The effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

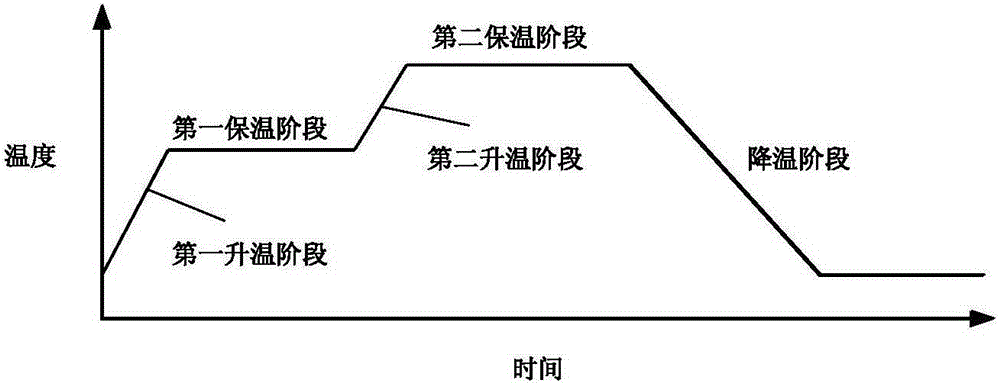

Method used

Image

Examples

Embodiment 1

[0056] Prepare the SiC PiN substrate

[0057] The SiC epitaxial wafer of NORSTEL Company is purchased as the silicon carbide PiN substrate used in the present invention. The SiC epitaxial wafer includes an N-type SiC substrate, an N-type SiC epitaxial layer and a P-type SiC epitaxial layer in sequential contact, wherein the thickness of the N-type SiC substrate is 350 μm±25 μm, and the resistivity is 15-25mΩ·cm; N The doping concentration of the type epitaxial layer is 3E15cm -3 ; The thickness of the P-type epitaxial layer is 1 μm, and the doping concentration is 2E18cm -3 .

Embodiment 2

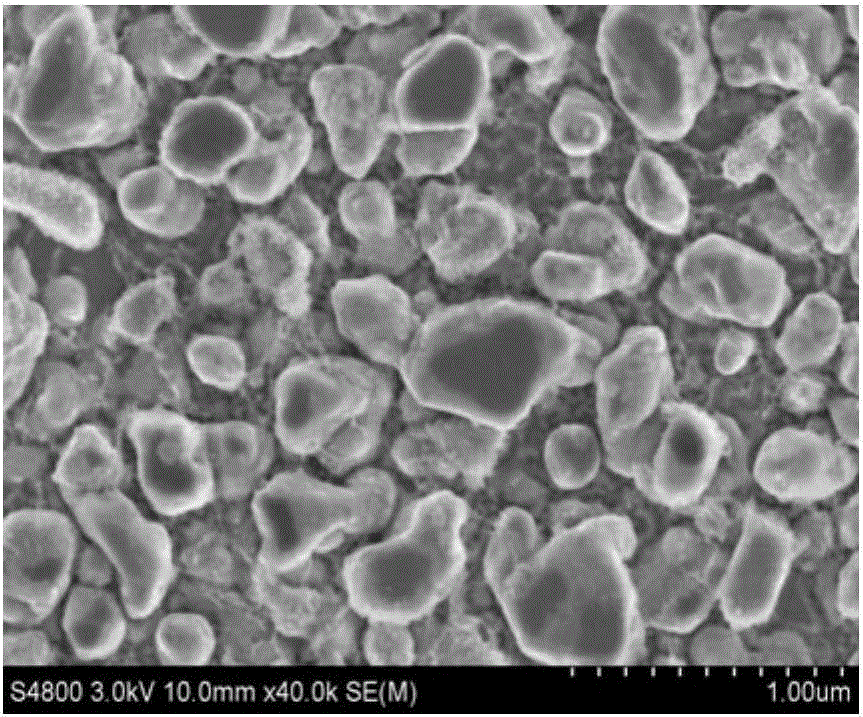

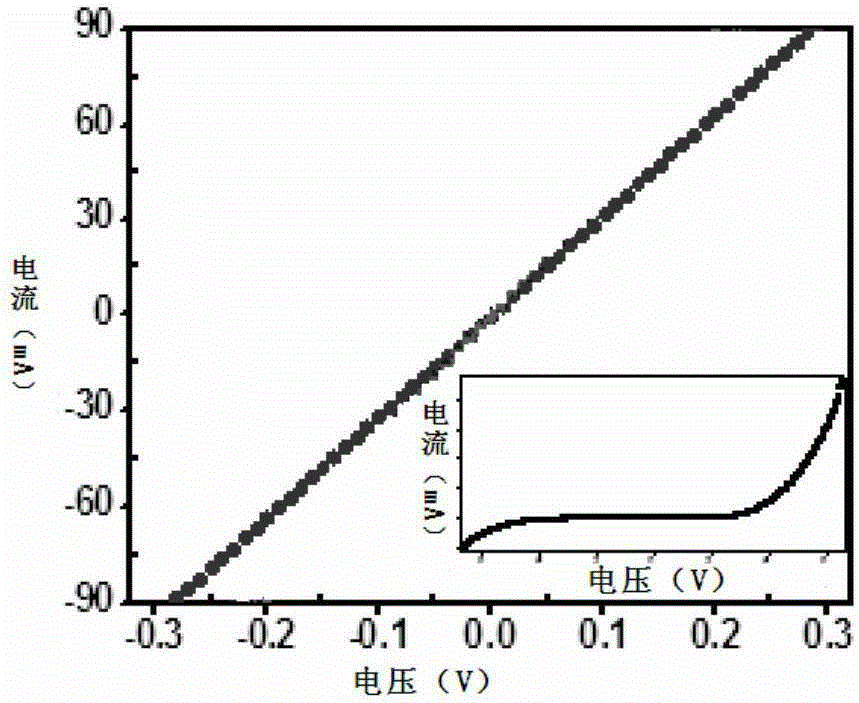

[0059] Fabrication of Silicon Carbide PiN Devices Forming Ohmic Contacts

[0060] 1), substrate P-type SiC epitaxial layer protection:

[0061] A low-pressure chemical vapor deposition (LPCVD) method is used to epitaxially grow an amorphous silicon layer with a thickness of 10 nm on the surface of the P-type SiC epitaxial layer of the silicon carbide PiN substrate described in Example 1. Among them, the temperature of epitaxial growth is 400-415°C, the pressure of epitaxial growth is 200-225mtorr, and the reaction gas used for epitaxial growth is SiH 4 , the carrier gas is N 2 .

[0062] 2), the surface treatment of the base N-type SiC substrate before metal sputtering:

[0063] According to HF:H 2 The mass ratio of O=1:5 will be HF and H 2 O mixed to obtain the pickling solution; the silicon carbide PiN substrate treated in step 1) was placed in a standard flower basket, and the flower basket was placed in the pickling solution, requiring the pickling solution to complet...

Embodiment 3

[0075] 1), substrate P-type SiC epitaxial layer protection:

[0076] A low-pressure chemical vapor deposition (LPCVD) method is used to epitaxially grow an amorphous silicon layer with a thickness of 15 nm on the surface of the P-type SiC epitaxial layer of the silicon carbide PiN substrate described in Example 1. Among them, the temperature of epitaxial growth is 500-525°C, the pressure of epitaxial growth is 250-275mtorr, and the reaction gas used for epitaxial growth is SiH 4 , the carrier gas is N 2 .

[0077] 2), the surface treatment of the base N-type SiC substrate before metal sputtering:

[0078] According to HF:H 2 The mass ratio of O=1:6 will be HF and H 2 O mixed to obtain the pickling solution; the silicon carbide PiN substrate treated in step 1) was placed in a standard flower basket, and the flower basket was placed in the pickling solution, requiring the pickling solution to completely immerse the wafer, and gently shaking the flower basket, The time is 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com