Low-g micromechanical acceleration latching switch

A micro-mechanical and acceleration technology, applied in electrical switches, contacts, electrical components, etc., can solve the problems that contacts are easily affected by external shock or vibration, easily interfered by the external environment, and difficult to meet the requirements of use. Convenient blocking threshold, wide threshold range, beneficial effect of structure release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments of the present invention are described in detail below. For the experimental methods that do not specify specific conditions in the examples, usually follow the conventional conditions or the conditions suggested by the manufacturer.

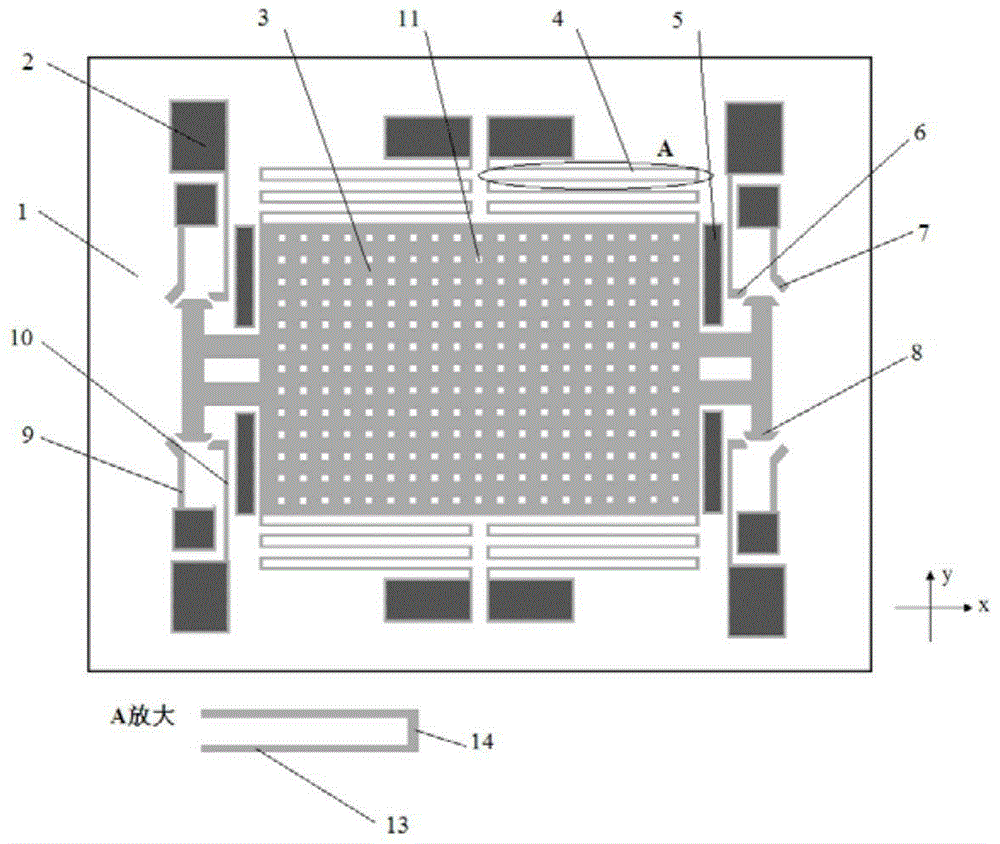

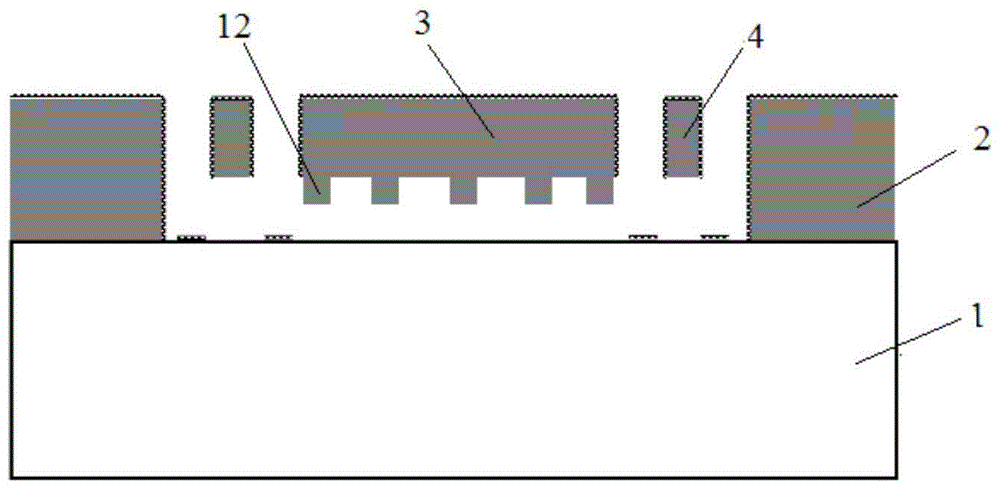

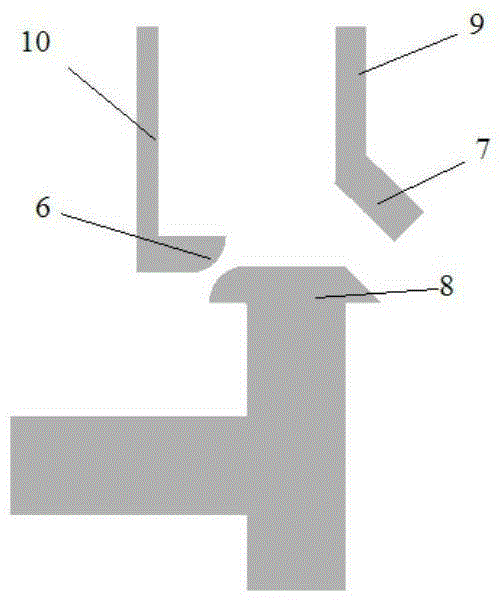

[0033] Wherein, the components represented by each reference numeral are as follows: 1-insulating substrate; 2-anchor point; 3-proof mass block; 4-proof mass block support beam; 5-overload protection structure; Induction contact; 8-moving contact; 9-induction contact support beam; 10-side contact support beam; 11-mass microhole; 12-mass microcolumn; 14 - proof mass support beam short beam.

[0034] The micro-mechanical acceleration switch of the present invention includes an insulating substrate, an anchor point, a contact, a disturbance beam (a contact support beam and a detection mass support beam), a detection mass and an overload protection structure.

[0035] Such as figure 1 As shown, the horizontal directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com