Low temperature thermal conductivity measurement method

A measurement method and technology of thermal conductivity, which is applied in the field of measurement of thermal conductivity of solid materials, can solve problems such as weak triple frequency voltage signal, inaccurate measured value of thermal conductivity of thin film, small temperature coefficient of resistance of metal conductor wire, etc. Achieve the effect of improving measurement accuracy, improving measurement accuracy and effectiveness, and avoiding deviation of measurement values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

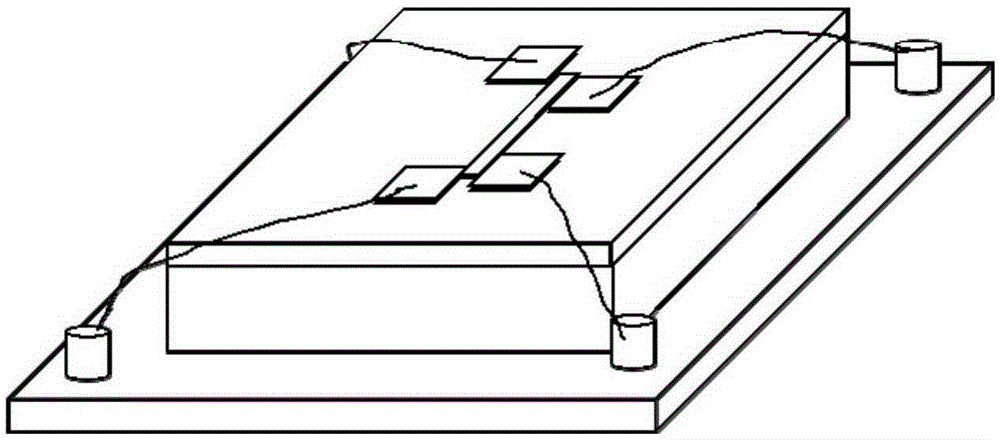

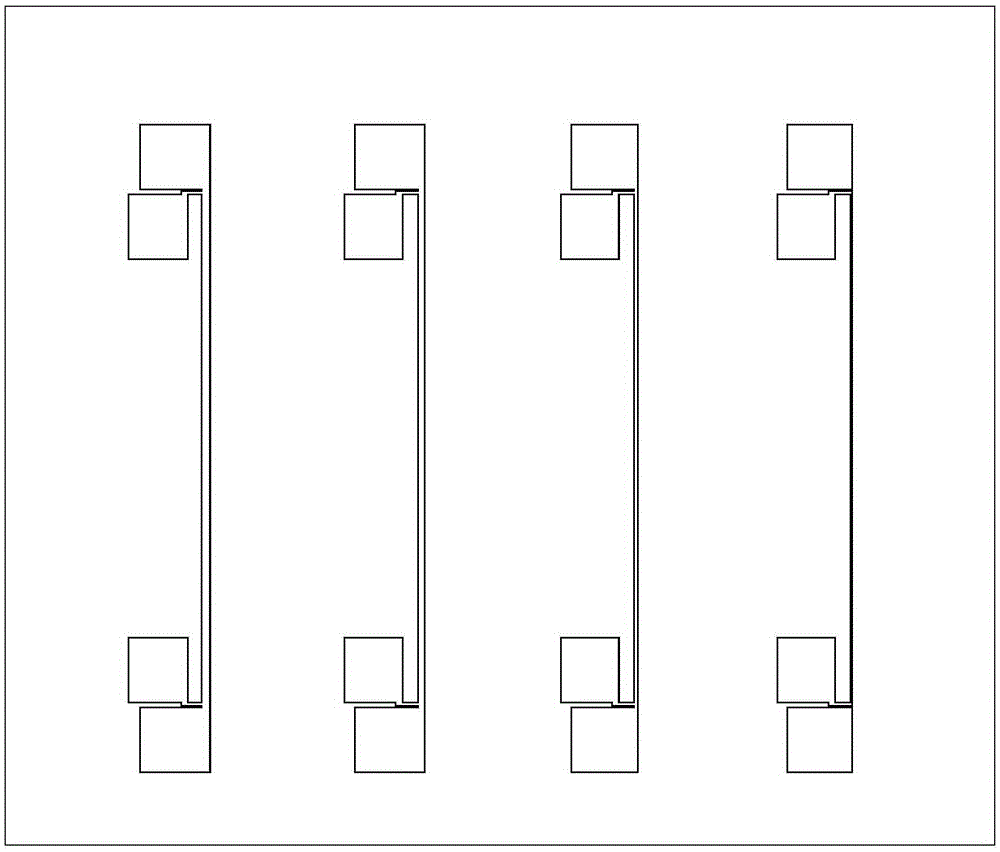

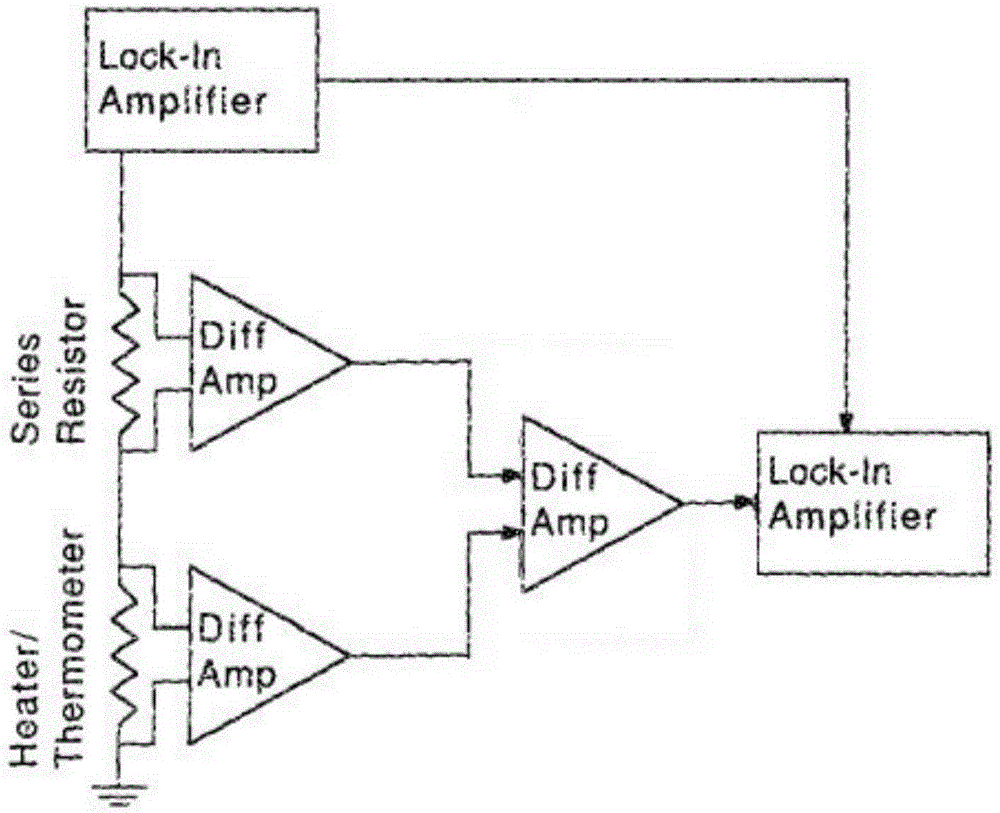

[0032] The concrete implementation method of the present invention is as follows. It is mainly divided into two parts: device fabrication and data measurement. The following is the implementation steps of a typical measurement example.

[0033] 1. Device fabrication

[0034] 1) Sample acquisition: the sample material is prepared or cut into rectangular slices with a size of 5 mm×7 mm, and a thickness of about 0.4-0.6 mm.

[0035] 2) Surface cleaning: put the sample into analytical pure trichlorethylene for 5 minutes, ultrasonic cleaning in analytical pure acetone for 5 minutes, ultrasonic cleaning in analytical pure isopropanol for 5 minutes, and blow dry with high-purity nitrogen.

[0036] 3) Drying: The sample is baked on a hot plate at 100-200°C for 10-30 minutes.

[0037] 4) Glue rejection 1: Place the sample on a glue rejection table, add 1-2 drops of MicroChemPMGISF6 photoresist on the surface, and shake the glue at 4000r / min for 60s.

[0038] 5) Baking 1: Baking on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com