a solar converter

A converter and solar energy technology, applied in the field of solar energy utilization, can solve the problems of slow heat collection rate, low heat transfer efficiency and large heat dissipation loss of solar collectors, so as to achieve small heat dissipation loss, high heat transfer efficiency and safety. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

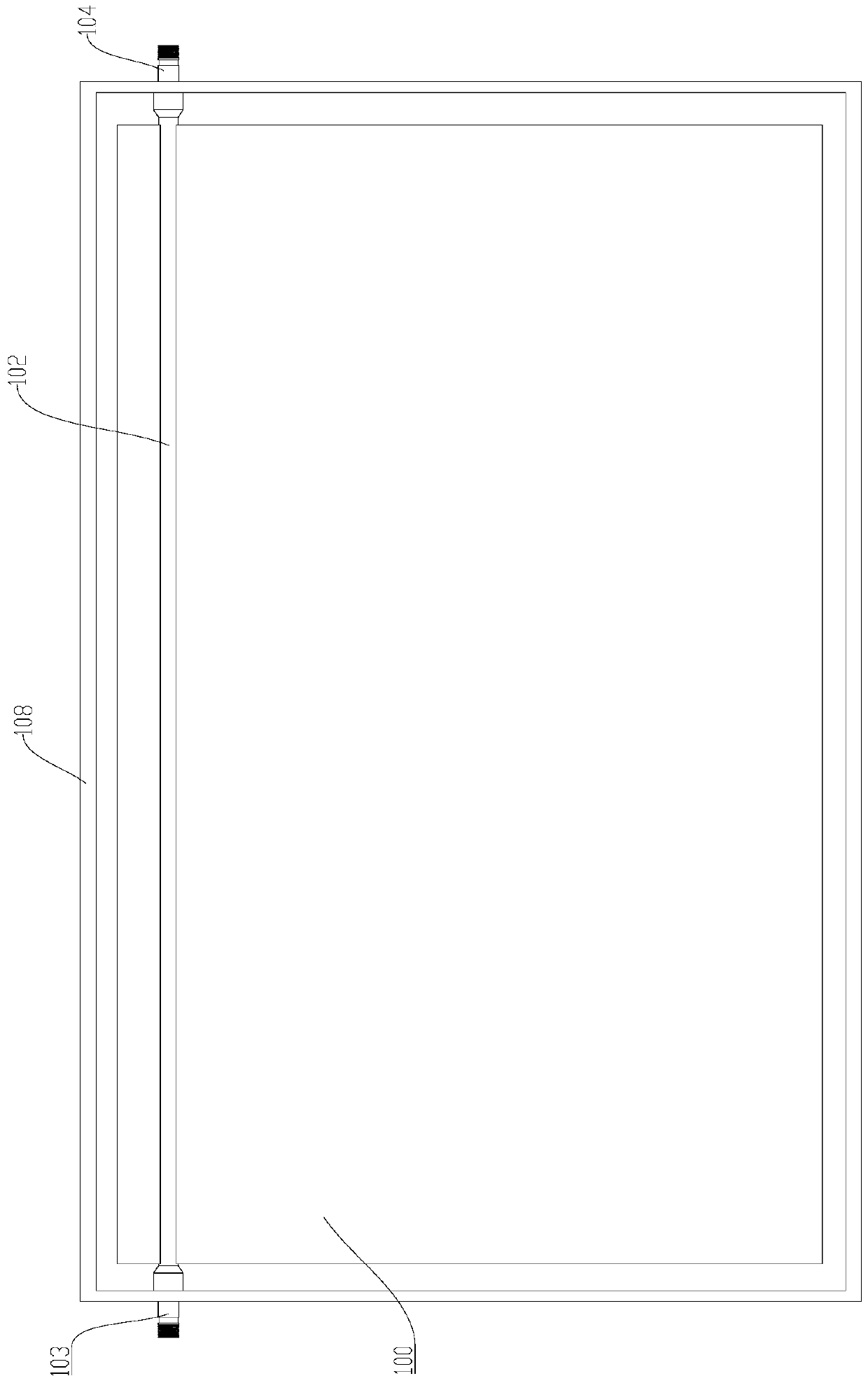

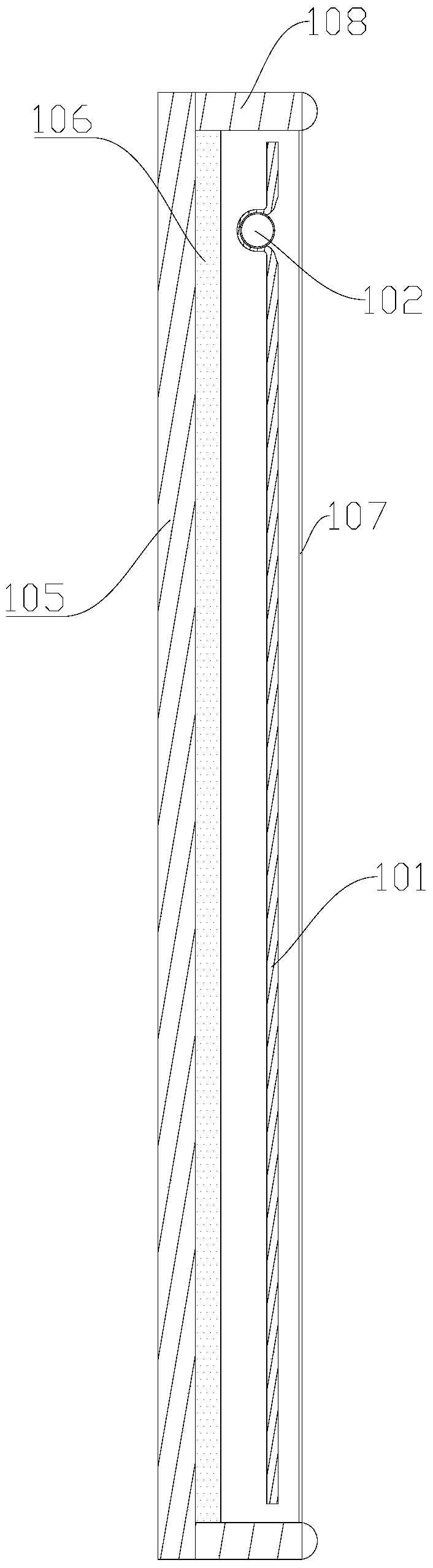

[0032] see figure 1 with figure 2 As shown, Embodiment 1 of the present invention provides a solar energy converter, including a heat collector plate core 100 and a heat exchange flow pipe 102; the heat collector plate core 100 includes a first panel 101, and the first panel 101 is a flat micro heat pipe; The first panel 101 is connected to the heat exchange flow pipe 102, and the heat exchange flow pipe 102 is located at the upper end of the first panel 101. Specifically, the first panel 101 is provided with a limiting groove, and the heat exchange flow pipe 102 is engaged. In the limit groove, on the one hand, the movement of the heat exchange flow pipe 102 can be restricted, and on the other hand, the outer surface of the heat exchange flow pipe 102 can be in close contact with the first panel 101, increasing the contact between the two area, thereby increasing the heat conduction efficiency; the two ends of the heat exchange channel tube 102 are the water inlet 103 and t...

Embodiment 2

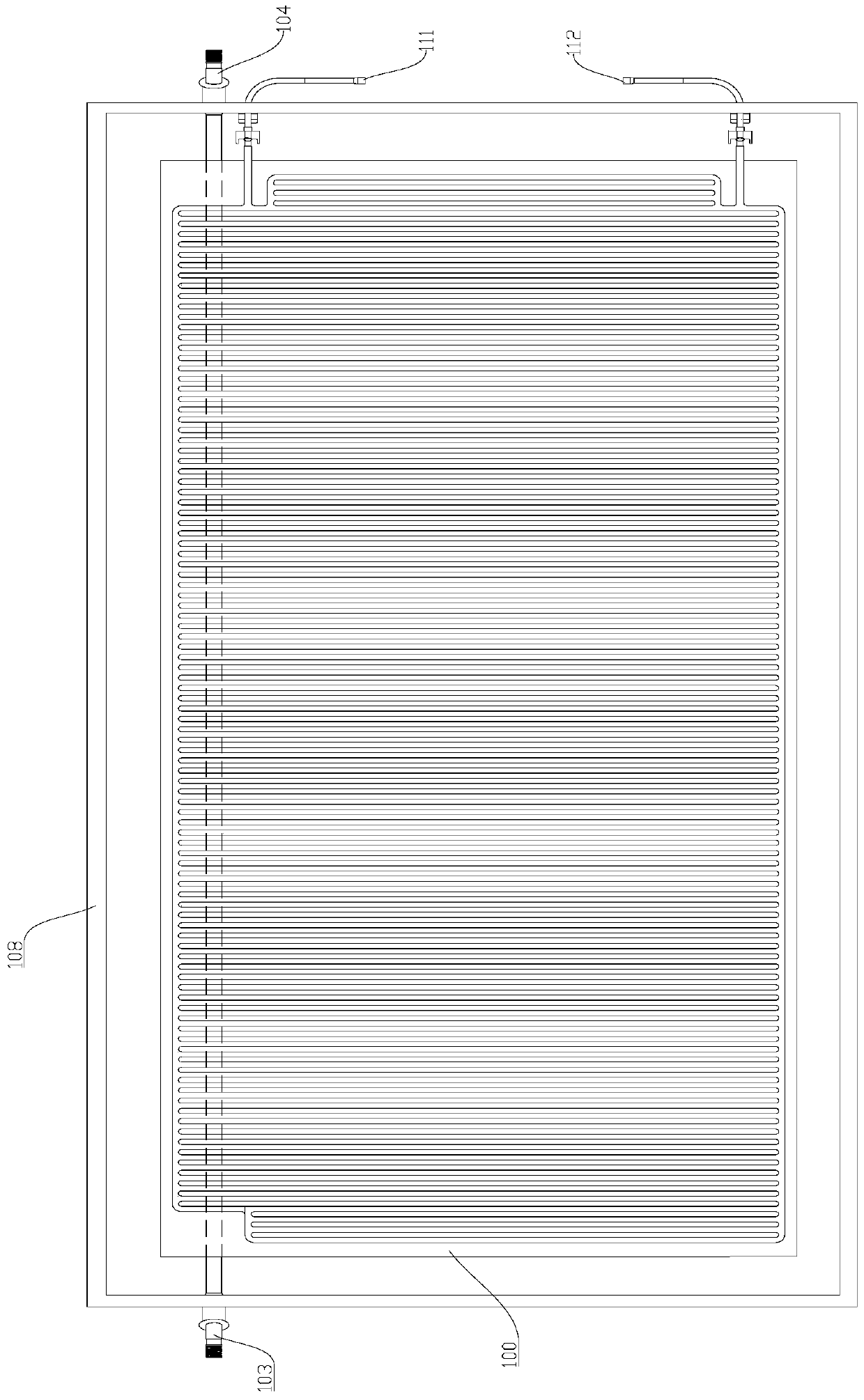

[0040] see image 3 with Figure 4As shown, Embodiment 2 of the present invention provides a solar energy converter, including a heat collector plate core 100 and a heat exchange flow pipe 102; the heat collector plate core 100 includes a first panel 101, and the first panel 101 is a flat micro heat pipe; The first panel 101 is connected with the heat exchange flow pipe 102, and the heat exchange flow pipe 102 is located at the upper end of the first panel 101; the two ends of the heat exchange flow pipe 102 are water inlet 103 and water outlet 104 respectively.

[0041] In the second embodiment, the solar energy converter also includes a second panel 109, and the second panel 109 is a flat micro heat pipe; the edge of the first panel 101 is sealed with the edge of the second panel 109, and the first panel 101 and the second panel 109 A plurality of liquid flow channels 110 are arranged between them, and the plurality of liquid flow channels 110 communicate with each other; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com