Preparation method for novel light-weight and high-strength protection armor plate

An armor plate and lightweight technology, which is applied in the field of preparation of new lightweight and high-strength protective armor plates, can solve problems such as strict weight requirements of equipment, and achieve the effects of increasing payload, low production cost, and easy industrialized preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Using 4mm thick LF21 aluminum alloy-12mm thick high damping superhard bulletproof sandwich layer, two-layer structure, the ratio of the thickness of the high damping superhard bulletproof sandwich layer to the thickness of the unilateral sandwich metal plate is 3:1;

Embodiment 2

[0033] Embodiment 2: Using 4mm thick LF21 aluminum alloy-16mm thick high damping superhard bulletproof sandwich layer, two-layer structure, the ratio of the thickness of the high damping superhard bulletproof sandwich layer to the thickness of the unilateral sandwich metal plate is 4:1;

Embodiment 3

[0034] Embodiment 3: Using 4mm thick LF21 aluminum alloy-24mm thick high damping superhard bulletproof sandwich layer, two-layer structure, the ratio of the thickness of the high damping superhard bulletproof sandwich layer to the thickness of the unilateral sandwich metal plate is 6:1;

[0035] The bulletproof effects of armor plates with different compositions are shown in the table. Unless otherwise stated, the percentages in the table are all mass fractions.

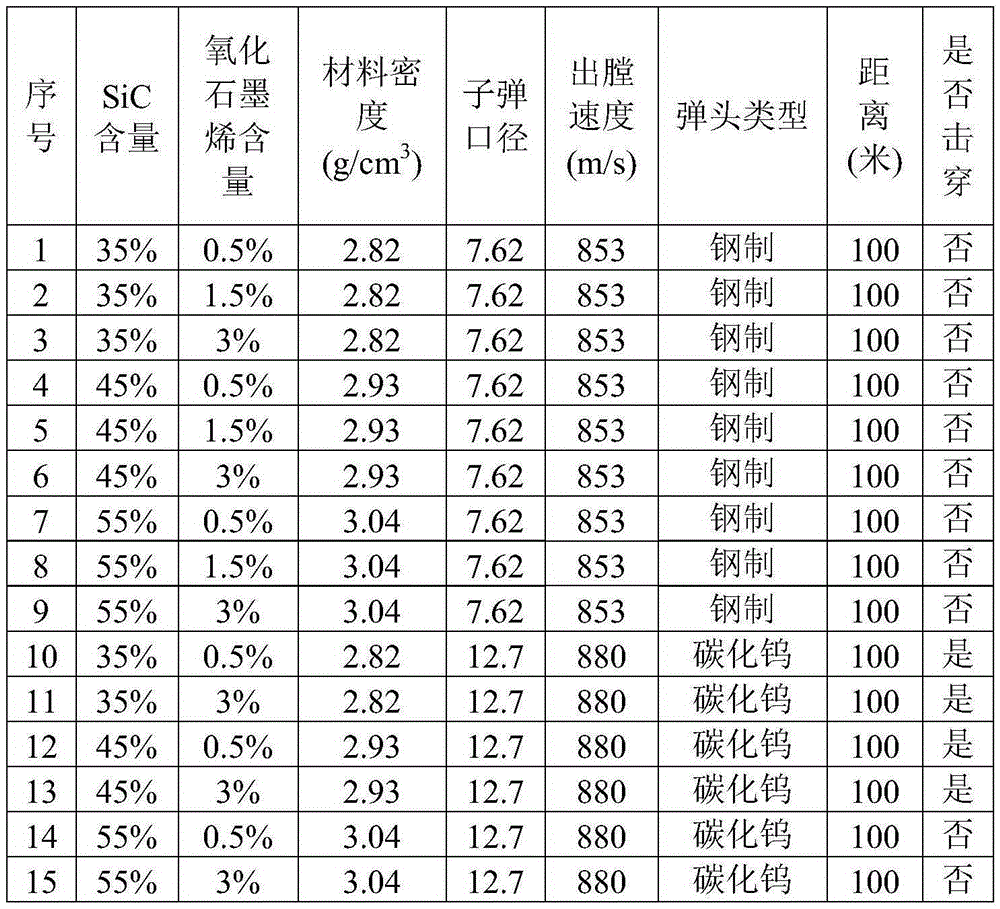

[0036] Table 1 Comparison of bulletproof effects of bulletproof panels with different components (thickness of sandwich layer: thickness of one side layer = 3:1)

[0037]

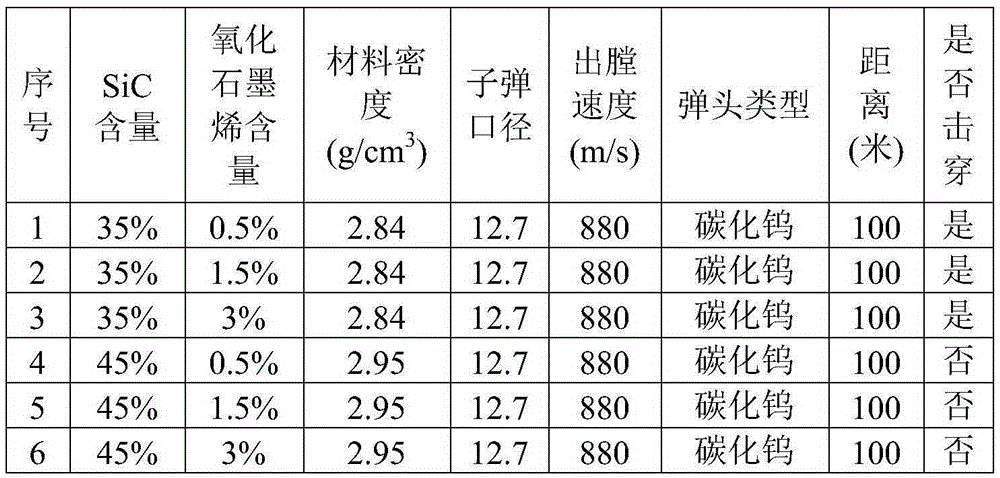

[0038] Table 2 Comparison of bulletproof effects of bulletproof panels with different components (thickness of sandwich layer: thickness of one side layer = 4:1)

[0039]

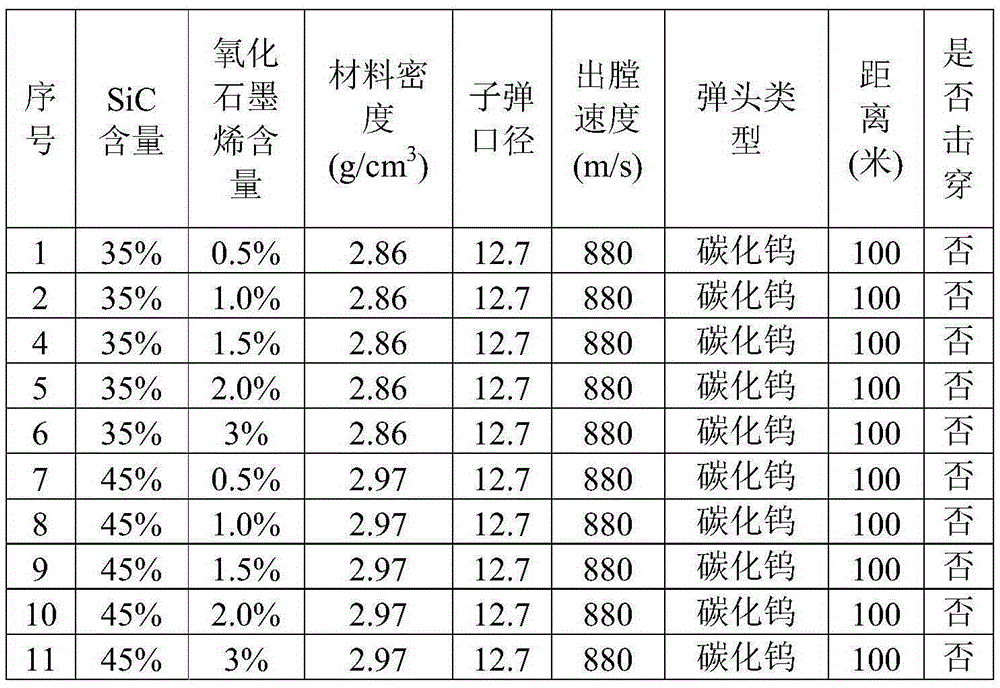

[0040] Table 3 Comparison of bulletproof effects of bulletproof panels with different components (thickness of sandwich layer: thickness of one side layer = 6:1)

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com