Separation purification method of urokinase

A technology for separation and purification of urokinase, applied in biochemical equipment and methods, enzymes, peptidases, etc., can solve problems such as inactivation of urokinase and infeasibility of urokinase, and achieve effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation of embodiment 1 urokinase crude product

[0038] a) Male urine, adjust the pH to 8.5 at a temperature below 10°C, let it stand for 2 hours, discard the precipitate, and obtain the supernatant;

[0039] b) Take the supernatant, adjust the pH to 5.0-5.5 and acidify to obtain acidified urine, which is adsorbed through a diatomite column;

[0040] c) Wash the column with cold water at 5°C, and elute with 1% ammonia water and sodium chloride to obtain an eluent;

[0041] d) The eluate was salted out with saturated ammonium sulfate and 4% ammonia water to obtain crude urokinase;

[0042] e) Add a certain amount of ammonia water to the precipitate to fully dissociate the urokinase in the precipitate to obtain a urokinase solution;

Embodiment 2

[0044] 1) To regenerate the medium, wash the QAE-Sephadex gel medium with 6 times the column volume of 1% sodium deoxycholate, and then wash the gel medium with 8 times the column volume of water;

[0045] 2) Gel medium pretreatment, called gel medium, suspended in distilled water, poured off the upper layer of fine particles after 1 hour, and soaked the gel medium in 0.5NNaOH solution at a ratio of 15ml of 0.5NNaOH solution per gram of gel medium medium, stir well, let stand for 30 minutes, filter with suction, wash with distilled water until the pH is neutral; then treat with 0.5N HCl solution as above, and finally treat with 0.5N NaOH solution again, after treatment, soak the gel medium Overnight in 0.1M pH7.4 phosphate buffer;

[0046] 3) Pack the column, suspend the gel medium, take an appropriate amount of gel and fill it in the chromatography column, wash the gel with 3 to 5 times the column volume of water or buffer; pack the column;

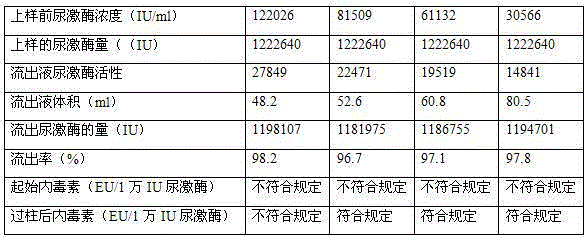

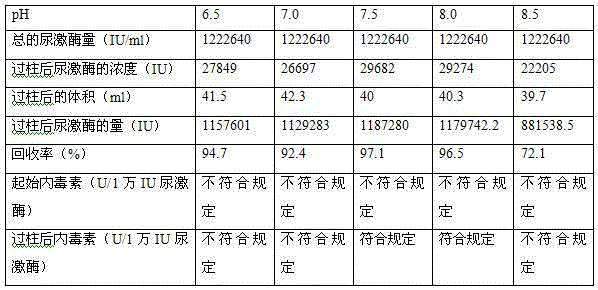

[0047] 4) Equilibrium medium, eq...

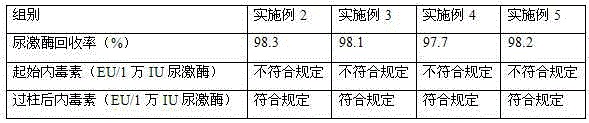

Embodiment 3

[0053] 1) To regenerate the medium, wash the DEAE-Sephadex gel medium with 6 column volumes of 1% sodium deoxycholate, and then wash the gel medium with 8 column volumes of water;

[0054] 2) Gel medium pretreatment, called gel medium, suspended in distilled water, poured off the upper layer of fine particles after 1 hour, and soaked the gel medium in 0.5NNaOH solution at a ratio of 15ml of 0.5NNaOH solution per gram of gel medium medium, stir well, let stand for 30 minutes, filter with suction, wash with distilled water until the pH is neutral; then treat with 0.5N HCl solution as above, and finally treat with 0.5N NaOH solution again, after treatment, soak the gel medium In 0.1M pH7.4 phosphate buffer overnight.

[0055] 3) Pack the column, suspend the gel medium, take an appropriate amount of gel and fill it in the chromatography column, wash the gel with 3 to 5 times the column volume of water or buffer; pack the column;

[0056] 4) Equilibrate the medium, equilibrate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com