Water-based fluorocarbon metal paint with high weather resistance and low voc and preparation method thereof

A water-based fluorocarbon and metallic paint technology, applied in the field of architectural decoration coatings, can solve the problems of low VOC weather resistance, low manufacturing cost, weak weather resistance, etc., and achieve improved water resistance, low manufacturing cost, and flexible construction methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

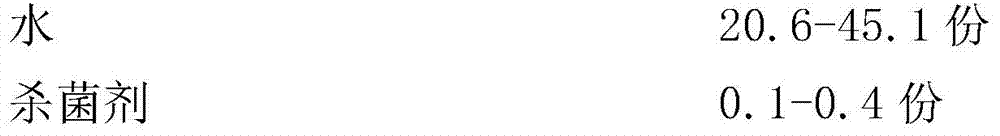

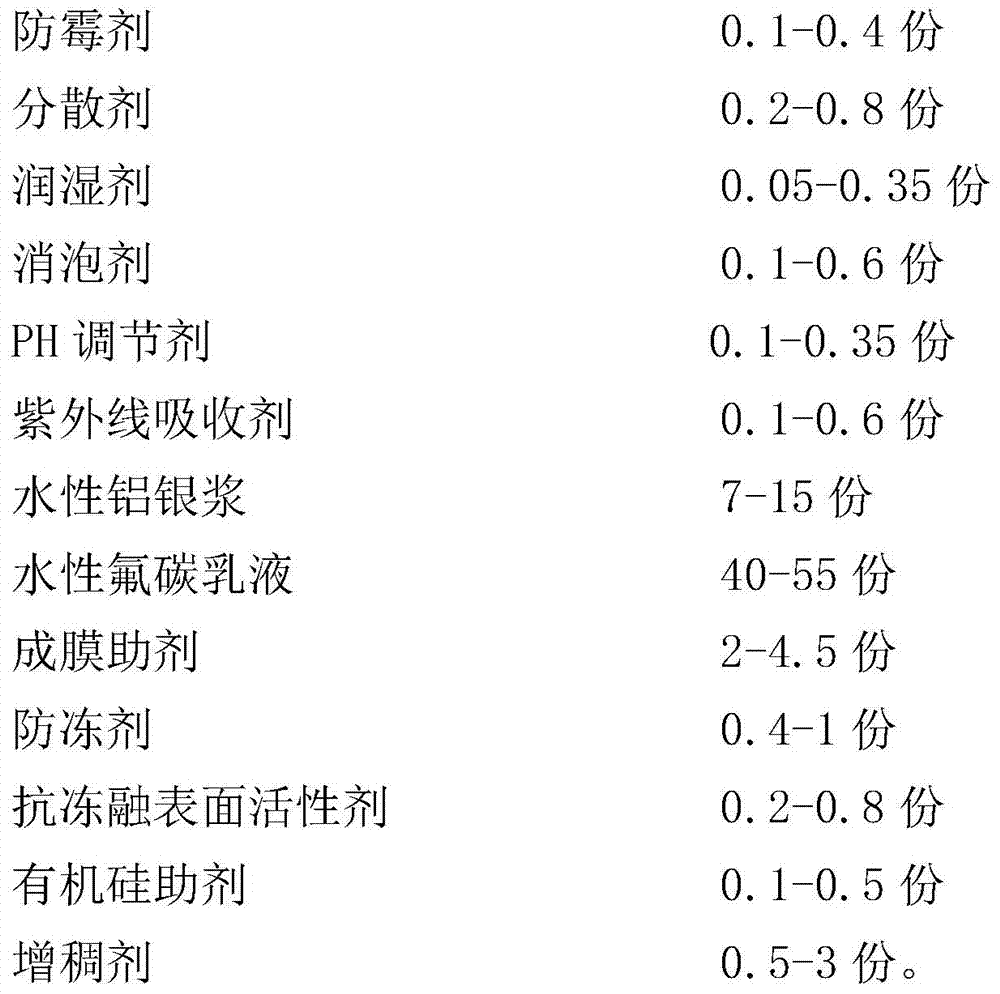

[0032] A water-based fluorocarbon metal paint with high weather resistance and low VOC is characterized in that: the paint is prepared from the following components according to the following proportions by weight:

[0033]

[0034]

[0035] The dispersant is one of ammonium salt dispersant or sodium salt dispersant or any mixture thereof.

[0036] The wetting agent is an anionic surfactant or a nonionic surfactant.

[0037] The defoamer is one or more of mineral oil defoamers, polyether modified defoamers or modified silicone defoamers in random mixture.

[0038] The solid content of the water-based fluorocarbon emulsion is 48-52%, and the fluorine content is 10-12%.

[0039] The thickener is one or more of polyurethanes, hydrophobically modified alkali-swellable thickeners or hydrophobically modified nonionic associative thickeners in random mixture.

[0040] The solid content of the water-based aluminum-silver paste is 50-55%, and the fineness of the aluminum powder...

Embodiment approach 2

[0042] A method for preparing high weather resistance and low VOC water-based fluorocarbon metal paint, characterized in that: the preparation method of the paint comprises the following steps in sequence:

[0043] 1) Add 20-25 parts of water, 0.1-0.4 parts of bactericide, 0.1-0.4 parts of anti-fungal agent, 0.2-0.8 parts of dispersant, 0.05-0.35 parts of wetting agent, 0.1-0.6 parts of defoamer, 0.1-0.35 parts of PH regulator and 0.1-0.6 parts of ultraviolet absorber, dispersed at this speed for 2-5 minutes;

[0044] 2) Adjust the rotation speed to 500-800 rpm, then add 7-15 parts of water-based aluminum silver paste at this rotation speed, and disperse at this rotation speed for 10-20 minutes until the silver powder is evenly dispersed;

[0045] 3) Then add 40-55 parts of water-based fluorocarbon emulsion at a speed of 500-800 rpm, and disperse for 3-5 minutes at this speed;

[0046] 4) Adjust the rotation speed to 700-1000 rpm, add 2-4.5 parts of film-forming aids, 0.4-1 p...

Embodiment 1

[0049] A water-based fluorocarbon metal paint with high weather resistance and low VOC is characterized in that: the paint is prepared from the following components according to the following proportions by weight:

[0050]

[0051] A method for preparing high weather resistance and low VOC water-based fluorocarbon metal paint, characterized in that: the preparation method of the paint comprises the following steps in sequence:

[0052] 1) Add 25 parts of water, 0.1 part of bactericide, 0.3 part of antifungal agent, 0.2 part of dispersant, 0.05 part of wetting agent, 0.1 part of defoamer, 0.35 part of PH regulator and 0.1 part of UV absorber, dispersed at this speed for 5 minutes;

[0053] 2) Adjust the rotation speed to 600 rpm, then add 7 parts of water-based aluminum silver paste at this rotation speed, and disperse at this rotation speed for 15 minutes until the silver powder is evenly dispersed;

[0054] 3) Then add 40 parts of water-based fluorocarbon emulsion at a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com