PHP mud manufacturing method and applications of PHP mud

A production method and mud technology, which are used in earth-moving drilling, wellbore/well components, sheet pile walls, etc., can solve problems such as unclear distribution relationship, and achieve the effects of reducing drill bit resistance, good stability, and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

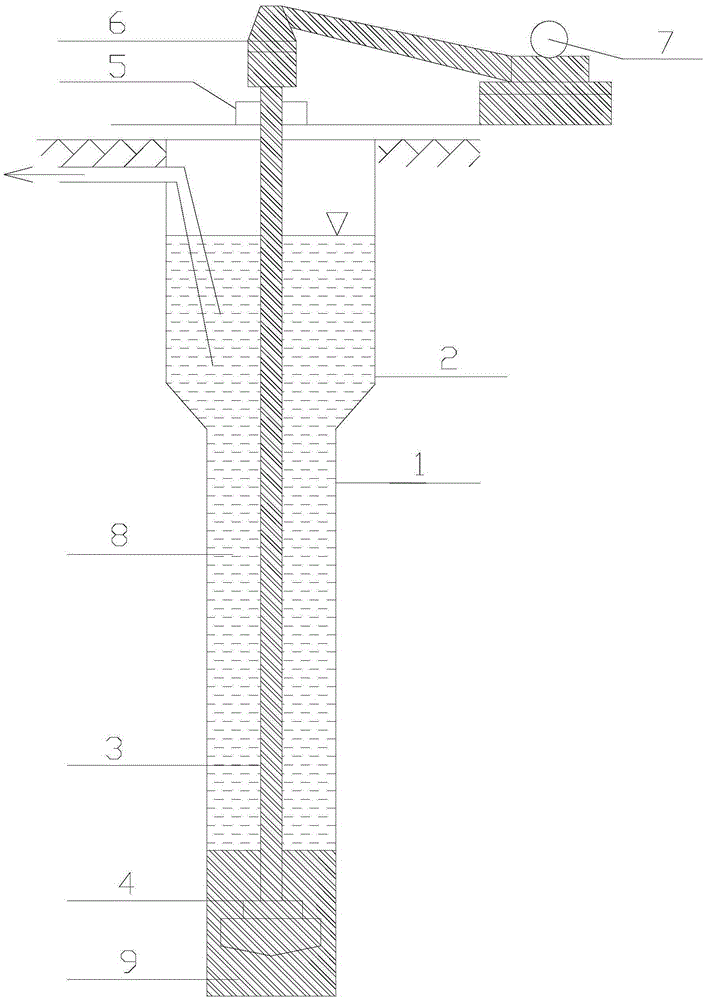

Image

Examples

Embodiment Construction

[0039] The present invention will now be further described in conjunction with specific examples. The following examples are intended to illustrate the present invention but not to further limit the present invention.

[0040] A method for making PHP mud, using bentonite, soda ash, hydroxymethyl cellulose and polyacrylamide as the main materials, wherein bentonite is 7% of the PHP mud volume, soda ash is 0.4% of the PHP mud volume, and hydroxymethyl fiber It is 0.08% of PHP mud volume, and polyacrylamide is 0.0032% of PHP mud volume;

[0041] The PHP mud is prepared by the following steps: select bentonite mud powder with colloid ratio ≥96% and sand content of 0-0.3%, and hydrolyze polyacrylamide at the same time: soak 100 parts of polyacrylamide in 6000 parts of water for 1 day At the same time, add caustic soda to stir in the mixing drum to promote the dissolution. The caustic soda is 10% of the hydrolyzed polyacrylamide. Leave it for 3 days to effectively disperse the hydrolyzed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com