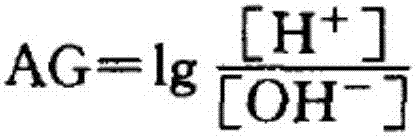

A kind of preparation method of naphthalene series water reducing agent

A technology of naphthalene-based water reducer and methylnaphthalene, which is applied in the field of concrete admixture preparation, can solve the problems of reducing the production cost of naphthalene-based water reducer, low concrete strength, and high air content, and achieves good adaptability, light weight reduction The effect of high water rate and strong plastic retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

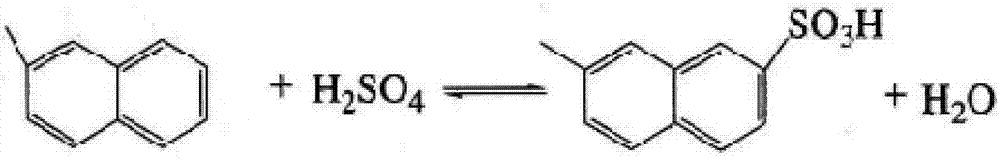

[0043] Sulfonated methylnaphthalene:

[0044] Weigh 2000kg of 83% industrial methylnaphthalene and 1655kg of 98% concentrated sulfuric acid respectively, put industrial methylnaphthalene into the sulfonation reactor, slowly heat up to 130°C, and evenly add 98% concentrated sulfuric acid dropwise to the sulfonation reactor for 40min, The temperature was controlled to rise to 160°C, and the stirring was continued for 2.5 hours, and the sulfonated methylnaphthalene obtained by the reaction was set aside.

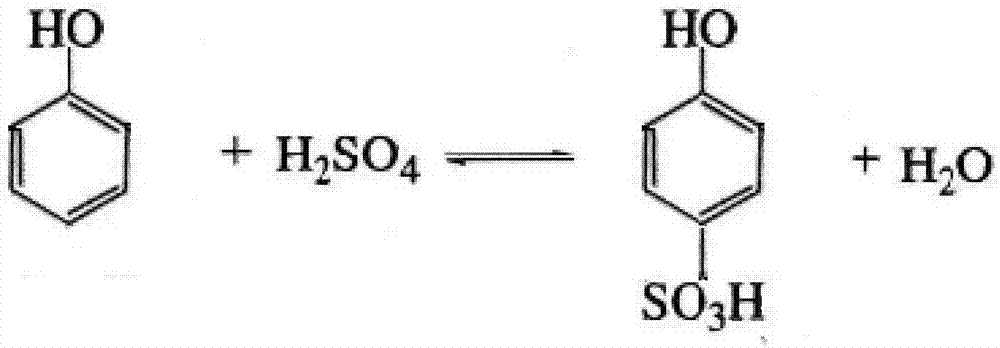

[0045] Phenol sulfonation:

[0046] Weigh 1325kg of liquefied phenol and 1550kg of 98% concentrated sulfuric acid respectively. Put the liquefied phenol into the sulfonation kettle, raise the temperature to 60°C, slowly add concentrated sulfuric acid dropwise and control the addition within 30 minutes, keep the temperature not exceeding 80°C, raise the temperature to 90°C after dropping the concentrated sulfuric acid, and carry out the sulfonation reaction for 2 hours , the obt...

Embodiment 2

[0054] Naphthalene sulfonation:

[0055] Weigh 1600kg of 83% industrial methylnaphthalene and 1545kg of 98% concentrated sulfuric acid respectively, put the industrial naphthalene into the sulfonation reactor, slowly raise the temperature to 130°C, and evenly drop 98% concentrated sulfuric acid into the sulfonation reactor for 30 minutes. Finish. The temperature was controlled to rise to 165° C., and the stirring was continued for 3 h, and the sulfonated methylnaphthalene obtained by the reaction was set aside.

[0056] Phenol sulfonation:

[0057] Weigh 1060kg of liquefied phenol and 1225kg of 98% concentrated sulfuric acid respectively. Put the liquefied methyl phenol into the sulfonation kettle, raise the temperature to 70°C, slowly add concentrated sulfuric acid dropwise and control the addition within 30 minutes, keep the temperature not exceeding 80°C, raise the temperature to 100°C after dropping the concentrated sulfuric acid, and sulfonate After reacting for 2.5h, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com