A method for continuous production of H-type phosphorus pentoxide

A technology of phosphorus pentoxide and yellow phosphorus, which is applied in the field of continuous production of h-type phosphorus pentoxide, can solve the problems of waste of heat energy, difficulty in crystal form control, low quality, etc., and improve the sedimentation velocity, fluidity and dispersion Good performance and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

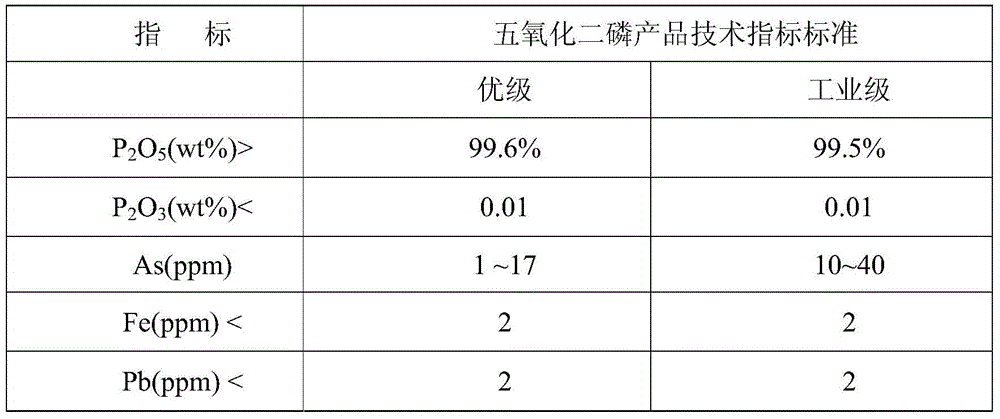

Embodiment 1

[0026] (1) Yellow phosphorus combustion: After heating and melting the yellow phosphorus at 60°C, it is transported to the combustion tower for combustion to generate high-temperature phosphorus pentoxide mixed gas. The combustion tower is provided with three layers of compressed air injection ports, which are upper, middle and lower layers. Among them, the lower injection port is equipped with one injection port, which simultaneously injects yellow phosphorus and dry compressed air, the injected air volume is 0.9 times the air volume required for the combustion of yellow phosphorus theoretically, and the middle injection port has two injection ports. The amount of injected air is 0.5 times the theoretical amount of air required for the combustion of yellow phosphorus. The upper injection port is equipped with 2 injection ports. The amount of injected air is 0.3 times the amount of air required for the theoretical yellow phosphorus combustion. The discharge temperature of the com...

Embodiment 2

[0033] (1) Yellow phosphorus combustion: After heating and melting the yellow phosphorus at 75°C, it is transported to the combustion tower for combustion to generate high-temperature phosphorus pentoxide mixed gas. The combustion tower is provided with three layers of compressed air injection ports, which are upper, middle and lower layers. Among them, the lower injection port is equipped with one injection port, which simultaneously injects yellow phosphorus and dry compressed air, the injected air volume is 0.5 times the amount of air required for the combustion of yellow phosphorus theoretically, and the middle injection port has 4 injection ports. The amount of injected air is 0.8 times of the theoretical amount of air required for the combustion of yellow phosphorus. The upper injection port is equipped with 4 injection ports. The amount of injected air is 0.5 times of the theoretical amount of air required for the combustion of yellow phosphorus. The discharge temperature ...

Embodiment 3

[0038] (1) Yellow phosphorus combustion: After heating and melting the yellow phosphorus at 60°C, it is transported to the combustion tower for combustion to generate high-temperature phosphorus pentoxide mixed gas. The combustion tower is provided with three layers of compressed air injection ports, which are upper, middle and lower layers. Among them, the lower injection port is equipped with 2 injection ports, and the yellow phosphorus and dry compressed air are injected at the same time. The injected air volume is 0.75 times the air volume required for the combustion of yellow phosphorus theoretically. The middle injection port has 6 injection ports. The amount of injected air is 0.7 times of the theoretical amount of air required for the combustion of yellow phosphorus. The upper injection port is equipped with 6 injection ports. The amount of injected air is 0.4 times of the theoretical amount of air required for the combustion of yellow phosphorus. The discharge temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com