A forced feeder for a tablet press and its working method

A working method and technology of tablet presses, applied in the directions of presses, manufacturing tools, etc., can solve the problems of drug finished products not meeting production requirements, crushing secondary tableting loss, waste of pharmaceutical raw materials, etc., to achieve efficient cutting and crushing, and work. The effect of stable state and continuous guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

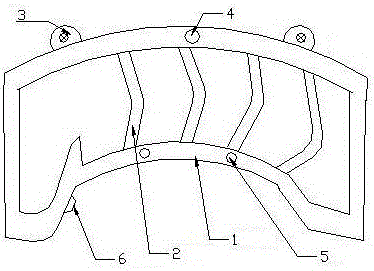

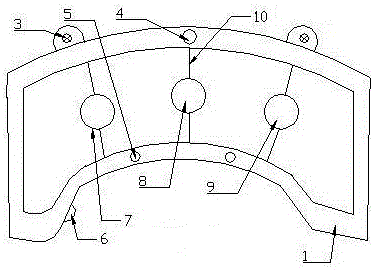

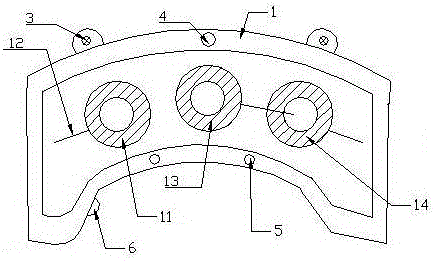

[0025] Such as figure 2 , image 3 , Figure 4 with Figure 8 A kind of forced feeder that is used for tablet press is shown, by housing 15, and the feeding pipe 16 that is arranged on the housing 15, and the feeding screen 17 that is arranged on the upper side of feeding pipe 16, and setting The pressing crushing assembly inside the housing 15 is composed of; the pressing crushing assembly includes the first roller bearing 7, the second roller bearing 8 and the third roller bearing 9 respectively arranged in the positioning plate 1, and the two connecting positioning plates 1 The end is used to fix the connecting rib 10 of the first roller bearing 7, the second roller bearing 8, and the third roller bearing 9, and is respectively arranged on the first roller bearing 7, the second roller bearing 8, and the third roller bearing 9 with The first rotating shaft 11, the second rotating shaft 13 and the third rotating shaft 14 used in conjunction with it, and the stirring teeth...

Embodiment 2

[0030] Such as Figure 5 , Image 6 , Figure 7 with Figure 8 A kind of forced feeder that is used for tablet press is shown, by housing 15, and the feeding pipe 16 that is arranged on the housing 15, and the feeding screen 17 that is arranged on the upper side of feeding pipe 16, and setting The pressing crushing assembly inside the housing 15 is composed of; the pressing crushing assembly includes the first roller bearing 7, the second roller bearing 8 and the third roller bearing 9 respectively arranged in the positioning plate 1, and the two connecting positioning plates 1 The end is used to fix the connecting rib 10 of the first roller bearing 7, the second roller bearing 8, and the third roller bearing 9, and is respectively arranged on the first roller bearing 7, the second roller bearing 8, and the third roller bearing 9 with The first rotating shaft 11, the second rotating shaft 13 and the third rotating shaft 14 used in conjunction with it, and the stirring teeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com