Quick blanking and drawing two-mode hydraulic machine and working method thereof

A hydraulic press and fast technology, applied in the field of hydraulic machinery, can solve the problems of high cost and price of mechanical presses, increased equipment occupied volume, insufficient hydraulic oil, etc., to reduce equipment investment costs, save space, and slide stably and smoothly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

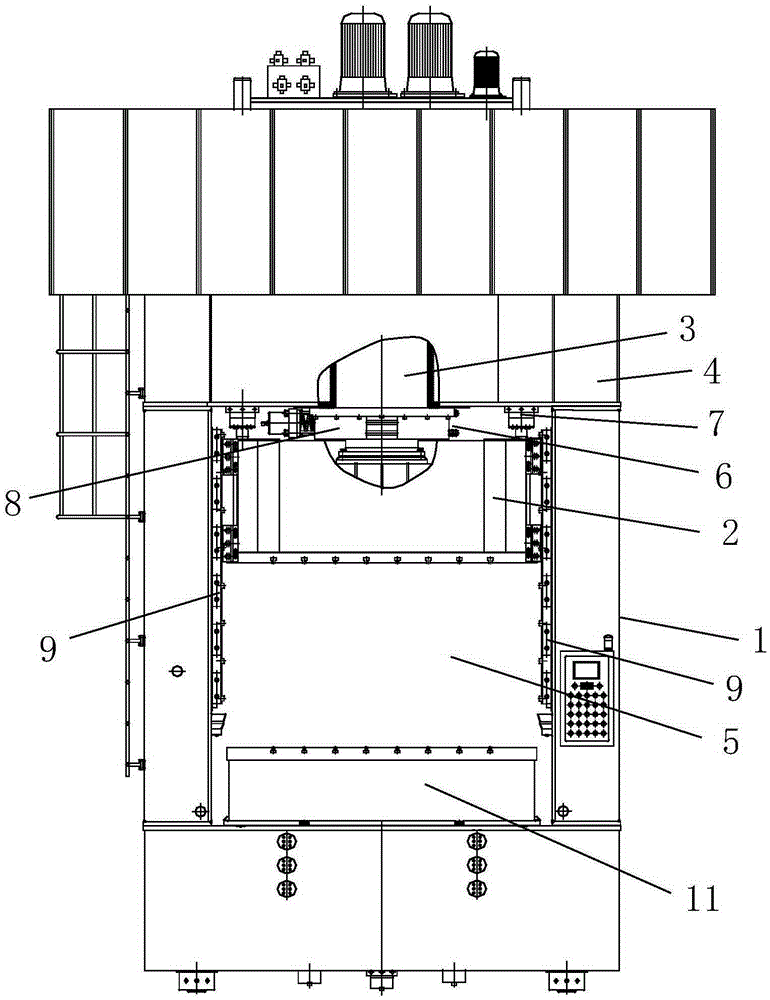

[0018] Such as figure 1 As shown, the rapid punching and stretching double-mode hydraulic press includes a frame 1 on which a sliding beam 2 and a pressurized oil cylinder 3 are installed.

[0019] The pressurized oil cylinder 3 is vertically and slidably installed on the upper beam 4 provided on the top of the frame 1, and the sliding beam 2 is slidably installed in the working chamber 5 provided in the middle of the frame 1. The plunger rod of the pressurized oil cylinder 3 and the sliding beam 2 connected.

[0020] Locking mechanism 6 is installed on the upper crossbeam 4, and the cylinder block of pressurized oil cylinder 3 is positioned at locking mechanism 6, and return stroke oil cylinder 7 is fixedly installed on the upper crossbeam 4, and the piston rod of return stroke oil cylinder 7 links to each other with sliding crossbeam 2.

[0021] During the initial state, the pressurized cylinder 3 and the sliding crossbeam 2 are all located at the top, and the piston rods a...

Embodiment 2

[0030] The structural composition of embodiment two is basically the same as that of embodiment one, the difference is that: locking mechanism 6 includes holding arm 8 and clamping driving device arranged left and right, and the inner wall of holding arm 8 is connected with the outer wall of cylinder by thread, and is held tightly. The arms 8 are all slidably installed on the upper beam 4, and the clamping drive device drives the clamping arms 8 to slide.

[0031] When it is necessary to position and lock the pressurized cylinder 3, the clamping drive device drives the two clasping arms 8 to close together, hugging the cylinder body of the pressurized cylinder 3, and the inner wall of the clasped arm 8 is threadedly engaged with the outer wall of the cylinder, through pressure and The threaded connection completes the fixing of the pressurized oil cylinder 3. The two locking methods work together to ensure a firm fixation.

[0032] The clamping driving device can be a power d...

Embodiment 3

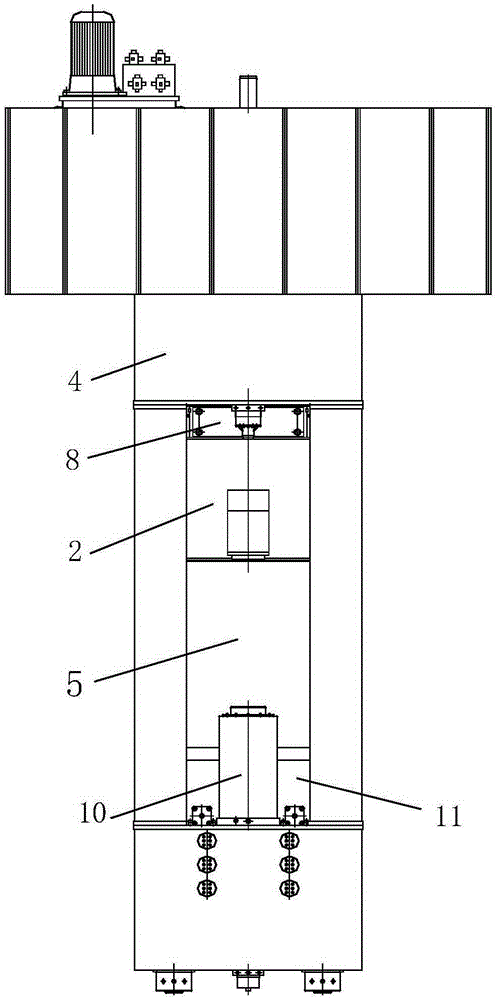

[0034] The structure composition of embodiment three is basically the same as that of embodiment one, the difference is: as figure 2 As shown, the two sides of the sliding beam 2 are correspondingly installed on the guide rails 9 vertically arranged on both sides of the working chamber 5 of the frame 1, and the buffer cylinder 10 is installed on the frame 1 corresponding to the lower end of the guide rail 9.

[0035] Sliding support on both sides of the sliding beam 2, and the lower part is blocked by the buffer cylinder 10 to ensure the stable operation of the sliding beam 2 and avoid excessive impact of the sliding beam 2 during fast punching, which will cause damage to the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com