Chelated iron desulfurizer and application method thereof

A technology of desulfurization agent and complex iron, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of poor stability of desulfurization liquid, achieve less liquid circulation, high desulfurization efficiency, and reduce equipment investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

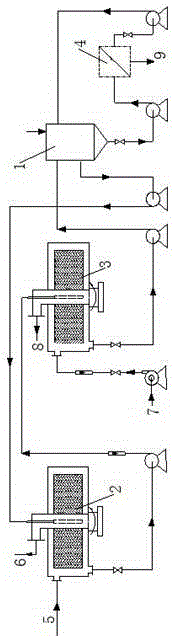

Image

Examples

Embodiment 1

[0054] Embodiment 1: the preparation method of complex iron desulfurizer:

[0055] Ferric ammonium sulfate, ferrous ammonium sulfate, citric acid, and HEDTA are formulated into a solution with a total iron concentration of 2.2g / L according to a molar ratio of 3:1:1.2:3.6, and Na 2 CO 3 19g / L, sodium benzoate 1.3g / L, composite sulfur particle sedimentation agent example a: 0.15g / L, multifunctional corrosion inhibitor example b: 0.4g / L to make complex iron desulfurizer;

Embodiment 2

[0056] Embodiment 2: the preparation method of complex iron desulfurizer:

[0057] Ferric ammonium sulfate, ferric sulfate, ferrous ammonium sulfate, NTA, and HEDTA are formulated into a solution with a total iron concentration of 7g / L in a molar ratio of 3:2:1:6:1.2, and NaOH and NaOH are added to the solution. 2 CO 3 The mixture of equal mass ratio is 35g / L, the mixture of sodium benzoate and sodium thiosulfate is 4.6g / L, the composite sulfur particle sedimentation agent example c: 0.66g / L, the multifunctional corrosion inhibitor example d: 1.3g / L to make complex iron desulfurizer;

Embodiment 3

[0058] Embodiment 3: the preparation method of complex iron desulfurizer:

[0059] Ferric ammonium sulfate, ferric sulfate, ferrous ammonium sulfate, gluconic acid, and NTA are prepared into a solution with a total iron concentration of 12g / L according to a molar ratio of 2:1:1:1:3.6, and KOH and K 2 CO 3 Mixture of equal mass ratio 48g / L, imidazole 7.2g / L, compound sulfur particle sedimentation agent example e: 1.1g / L, multifunctional corrosion inhibitor example c: 3.4g / L to make complex iron desulfurizer;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com