Method for producing polyurethane foam for cosmetic application, and polyurethane foam for cosmetic application

A technique of polyurethane foam and its manufacturing method, which is applied in the manufacture of polyurethane foam for cosmetic coating and the field of polyurethane foam for cosmetic coating, which can solve the problems of crushing the surface of powder cake, etc., and achieve the effect of good feeling of use and small environmental load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1~5

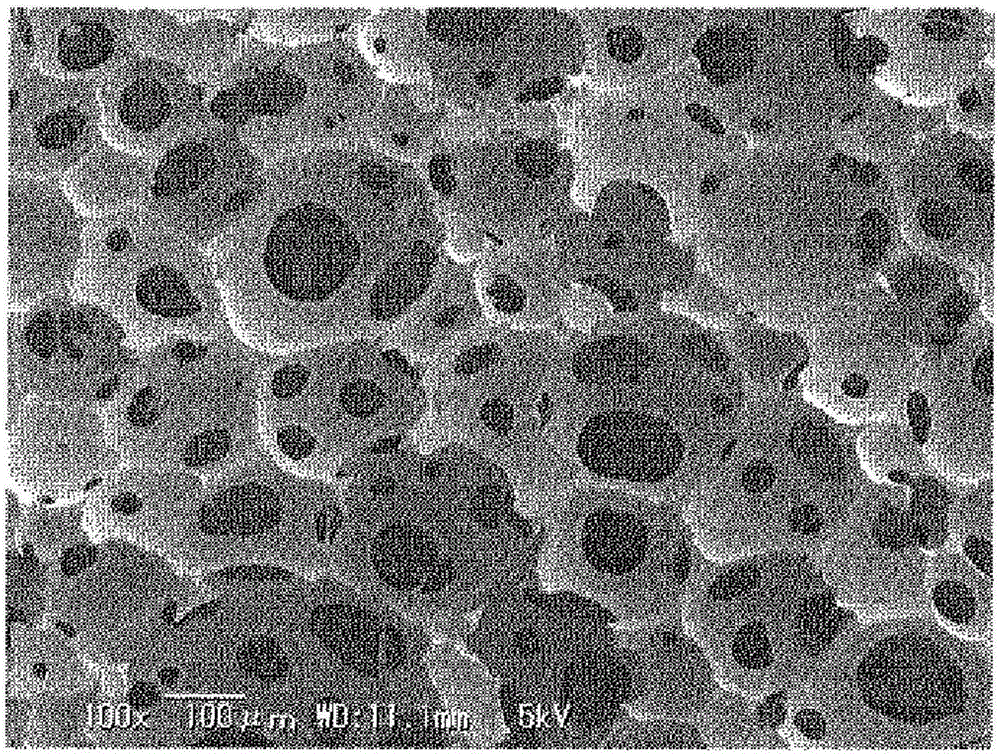

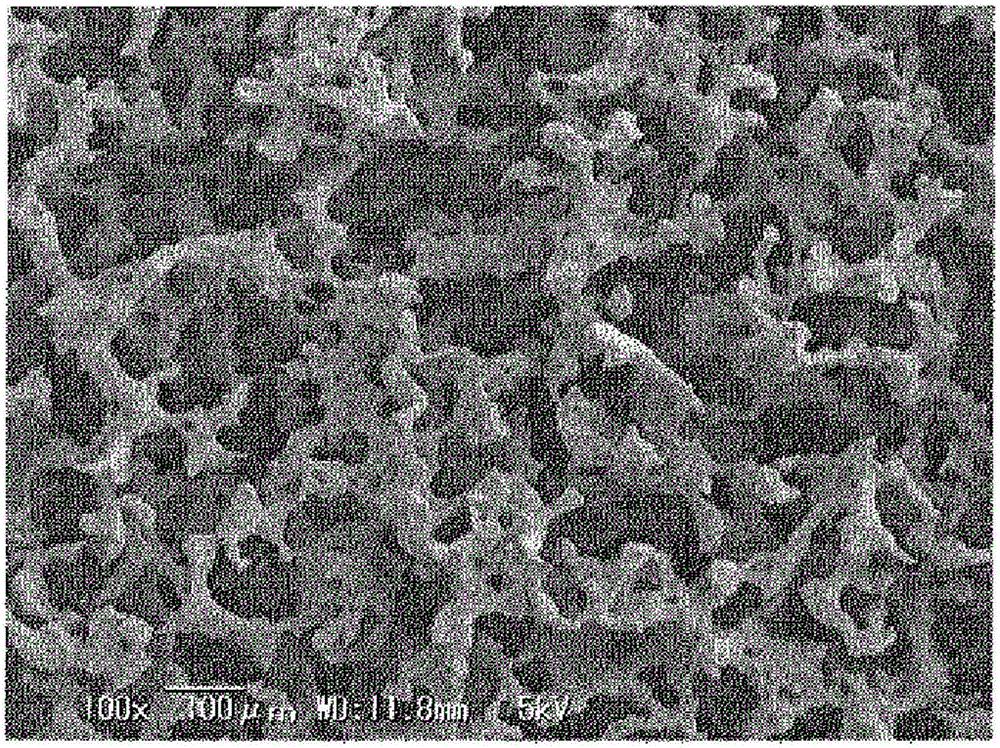

[0080] Using raw materials containing various polyols, using a disk-type Oaks mixer to produce polyurethane foam for cosmetic application by mechanical foaming, and studying the ease of introduction of inert gas, that is, the miniaturization of the cell diameter and the low density of the foam Polyols suitable for polyurethane foams for cosmetic coatings were studied based on the ease of chemical transformation and foam rupture.

Embodiment 1

[0082] In the presence of an acidic catalyst (addition polymerization catalyst), propylene oxide is added to an initiator with 2 functional groups to prepare a 2-functional polypropylene glycol with a terminal primary hydroxylation rate of about 70%, and further make the ring Oxyethane was added to prepare a bifunctional polyol (polyol A) having a terminal primary hydroxylation rate of 92% and a number average molecular weight of 1400.

[0083] Prepare polyol, crosslinking agent, foam stabilizer, amine catalyst (urethane reaction catalyst) and polyisocyanate as shown in Table 1. These raw materials are all liquid. Water is not used as blowing agent.

[0084] Table 1

[0085]

[0086] Continuously supply raw materials other than polyisocyanate to the Oaks mixer, spray while supplying nitrogen gas to react with polyisocyanate in the Oaks mixer, and ripen at 100°C for 7 minutes to produce polyurethane for makeup coating Foam.

[0087] At this time, the total supply rate of...

Embodiment 2

[0089] In the presence of an alkali catalyst, the addition polymerization of propylene oxide and the initiator with 2 functional groups is carried out, and the addition polymerization of ethylene oxide is further carried out to prepare a product with a terminal primary hydroxylation rate of 80% and a number average molecular weight of 2400 polyol (polyol B).

[0090] Raw materials were prepared in the same manner as in Table 1 except that polyol B was used instead of polyol A. In the same manner as in Example 1, a polyurethane foam for makeup application was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com