Method for preparing lithium ion membrane electrode through static coating, electrode and cell comprising electrode

A thin-film electrode, electrostatic coating technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as failure to achieve success, affecting slurry fluidity, and inability to meet needs, achieving good uniformity and broad application prospects , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing a thin film electrode, which is characterized in that it comprises the following steps:

[0037] (1) preparing positive electrode slurry and negative electrode slurry, wherein the solid content of the prepared positive electrode slurry is 20% to 35%, and the solid content of the prepared negative electrode slurry is 20% to 40%;

[0038] Generally, before electrostatic coating, the appropriate active material and other auxiliary materials are selected according to the requirements of the battery and thin film electrode to be prepared. In order to prepare a better thin film electrode, the particle size of the active material is generally required to be below 5 microns.

[0039] For the prepared electrostatic coating slurry, the electrostatic coating slurry is generally prepared according to the specific requirements of the thin film electrode, including adjusting the slurry viscosity, solid content, the proportion of active mat...

Embodiment 1

[0076] (1) According to the mass content of positive electrode active material lithium iron phosphate 16%, carbon black 5%, PVDF4%, with aluminum foil as positive electrode current collector as the carrier of active material, the ratio of NMP75% prepares positive electrode slurry 500g, wherein the lithium iron phosphate D. 50 It is 0.15 microns, and its solid content is 20%; according to the mass content of the negative electrode active material lithium titanate 18%, carbon black 3%, PVDF 4%, copper foil is used as the negative electrode current collector as the carrier of the active material, and the ratio of NMP75% is prepared Negative electrode slurry 500g, wherein D of lithium titanate 50 It is 0.15 microns, and its solid content is determined to be 20%.

[0077] (2) Add the above-mentioned prepared slurry to the electrospinning equipment for spraying, set the nozzle diameter to 1000 microns, the distance between the nozzle and the substrate to 10cm, the speed of the nozz...

Embodiment 2

[0080] (1) According to the mass content of positive electrode active material lithium iron phosphate 28%, carbon black 3%, PVDF4%, with aluminum foil as positive electrode current collector as the carrier of active material, the ratio of NMP65% prepares positive electrode slurry 500g, wherein the lithium iron phosphate D. 50 It is 4 microns, and its solid content is 35%; according to the mass content of the negative electrode active material lithium titanate 30%, carbon black 3%, PVDF 2%, copper foil is used as the negative electrode current collector as the carrier of the active material, and the ratio of NMP65% is prepared Negative electrode slurry 500g, wherein D of lithium titanate 50 It is 4 microns, and its solid content is determined to be 40%.

[0081] (2) Add the above-mentioned prepared slurry to the electrospinning equipment for spraying, set the nozzle diameter to 500 microns, the distance between the nozzle and the substrate to 15cm, the speed of the nozzle to 1...

PUM

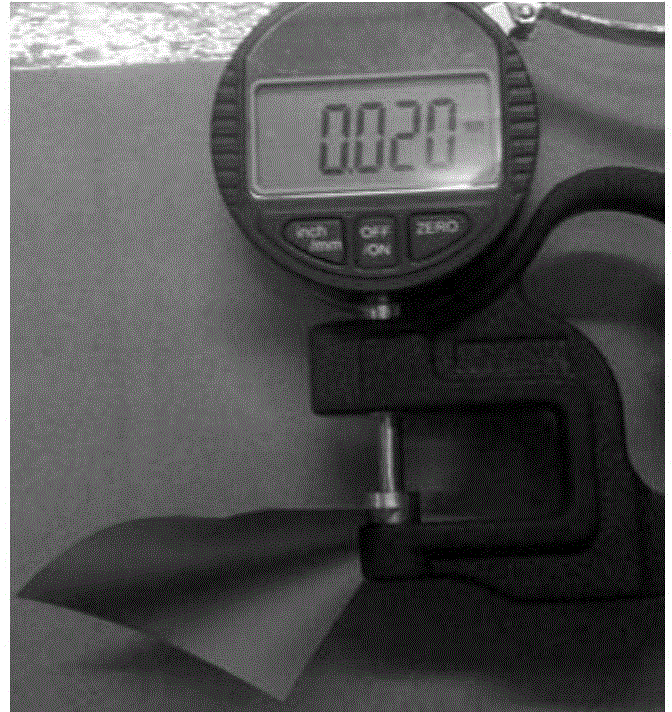

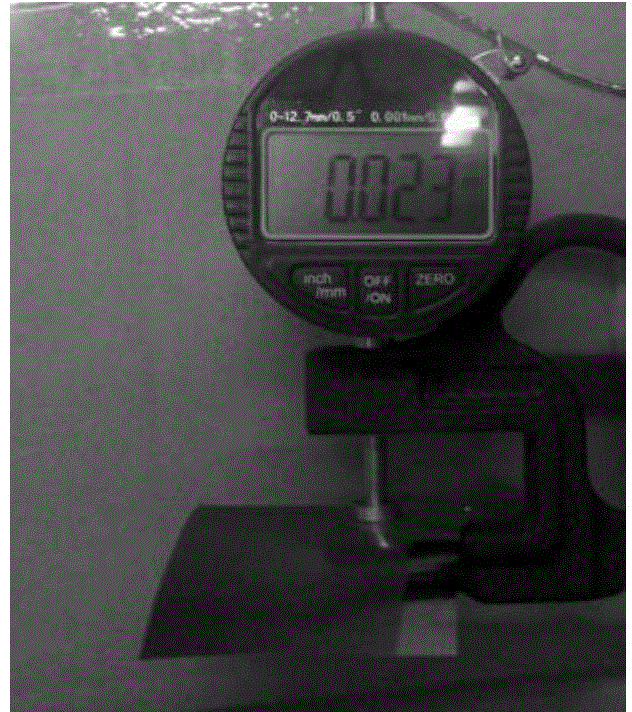

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com