A self-excited phase change thermal control cooling system

A heat dissipation system and phase change heat technology, applied in the direction of indirect heat exchangers, lighting and heating equipment, etc., can solve the problem that the condensate return method at the condensing end of the evaporation hot end needs to be improved, so as to enhance and condense the heat transfer effect and reduce the The effect of superheat and enhanced heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

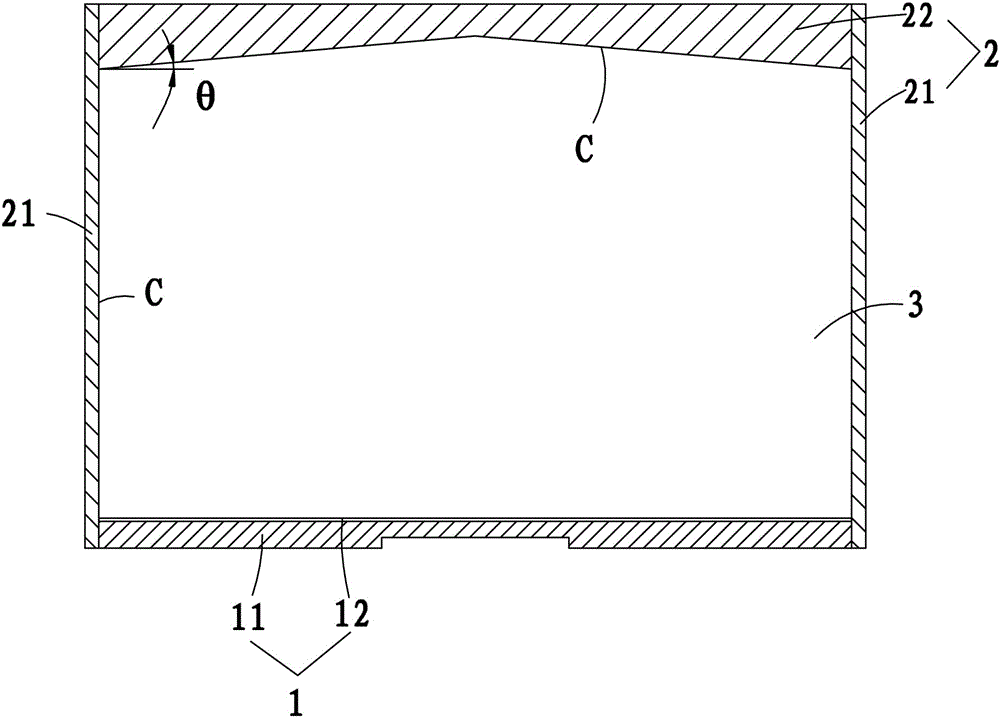

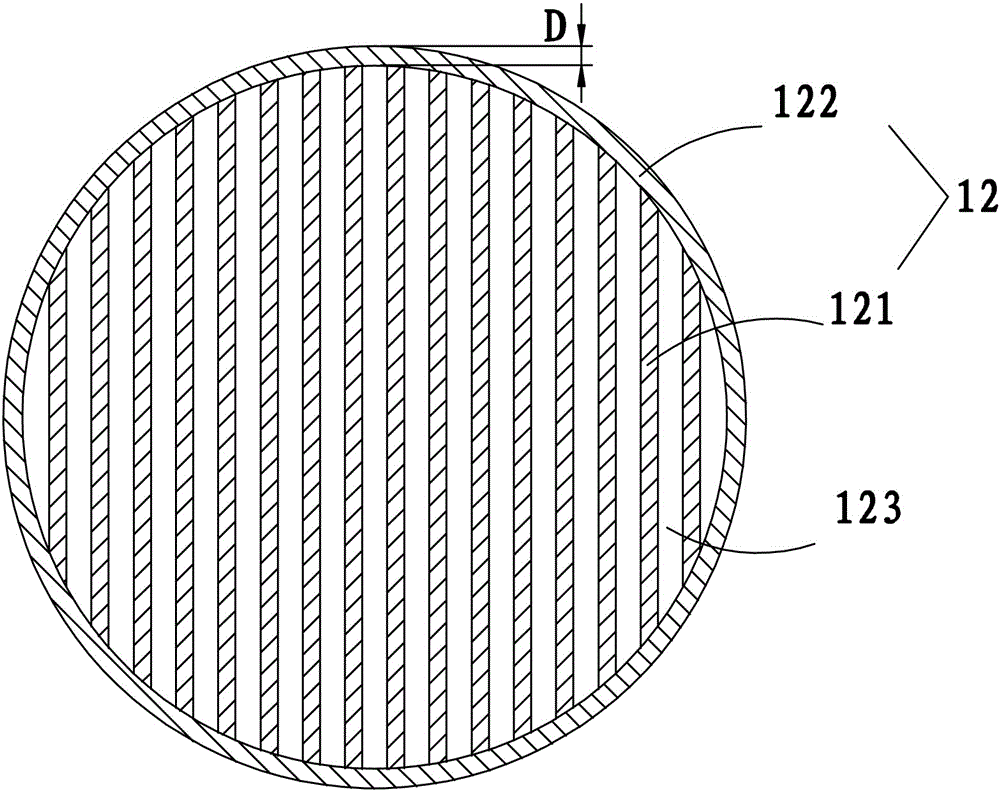

[0026] see Figure 1 to Figure 4 , the self-excited phase change thermal control and heat dissipation system of the present invention includes a heat extraction and evaporation module 1 and a condensation and heat dissipation module 2, and a seal for filling the working medium is formed between the heat extraction and evaporation module 1 and the condensation and heat dissipation module 2 The cavity 3, the heat-taking evaporation module 1 is located at one end of the closed cavity 3, and is composed of a heat-taking bottom plate 11 and an evaporation end surface microstructure 12, and the evaporation end surface microstructure 12 is arranged on the inner end surface of the heat-taking bottom plate 11, And it includes a capillary straight groove 121 and a liquid storage and supply groove ring 122 .

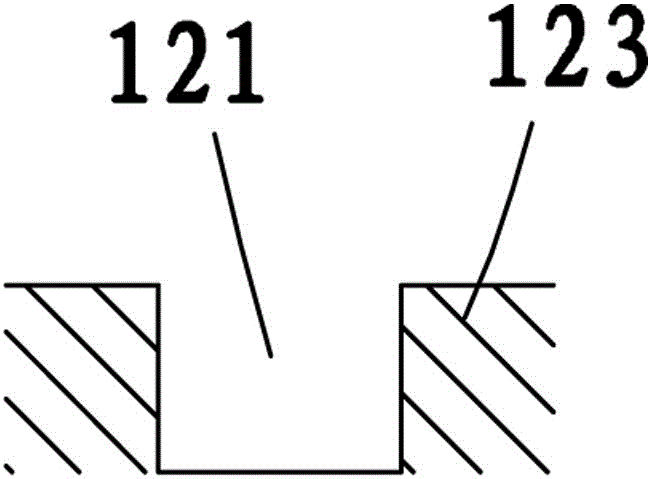

[0027] mainly as figure 2 As shown, the number of the capillary micro straight grooves 121 is multiple, and they are evenly distributed in parallel, and two adjacent capillary mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com