Wind power generation system with unipolar DC electromagnetic drive

A technology of wind power generation system and drive train, applied in wind power generation, wind turbine, wind turbine combination, etc., can solve the problem that "narrow-band" speed change cannot meet the optimal speed change requirements, large electromagnetic interference, and unfavorable maintenance and use of double-fed asynchronous generators And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

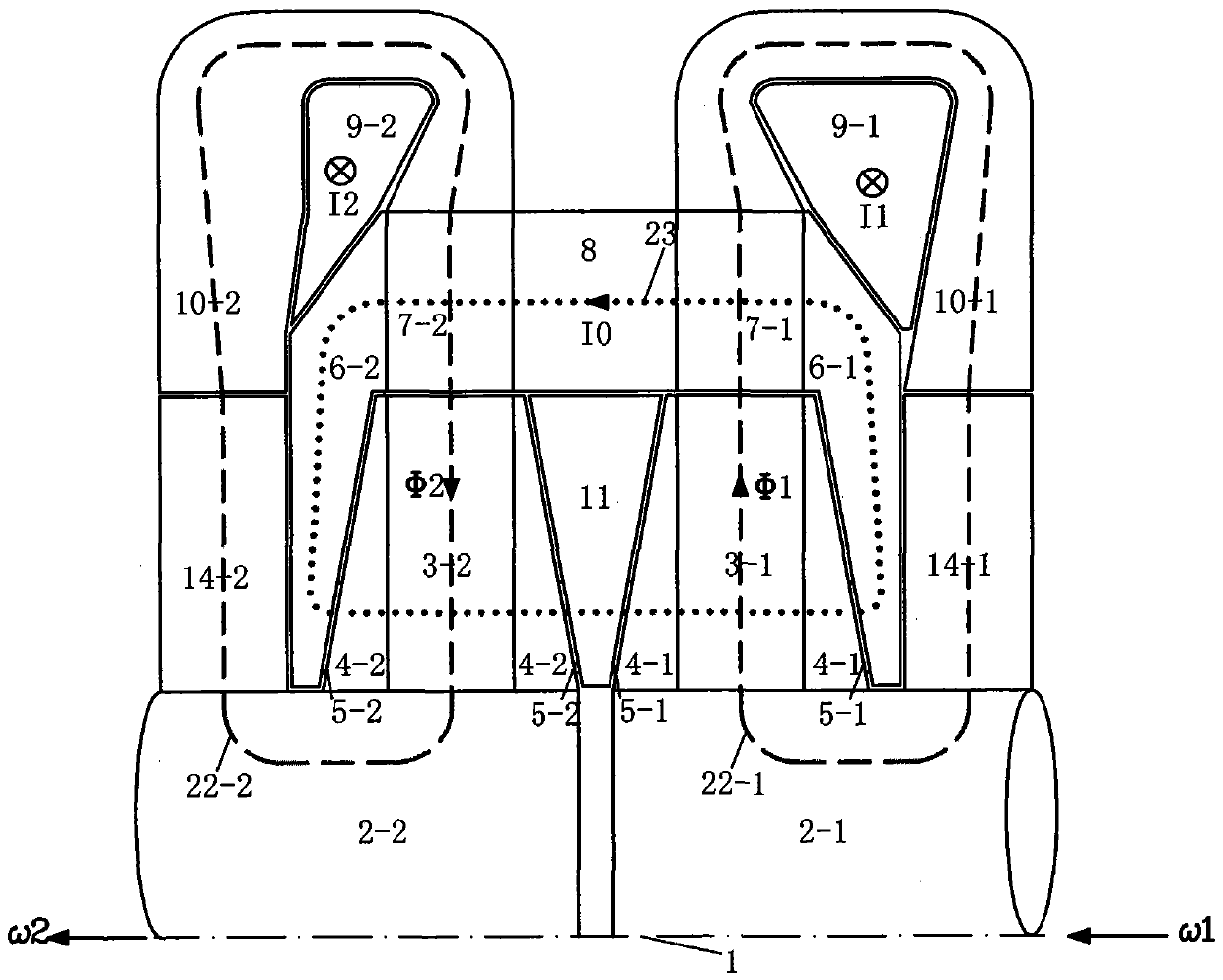

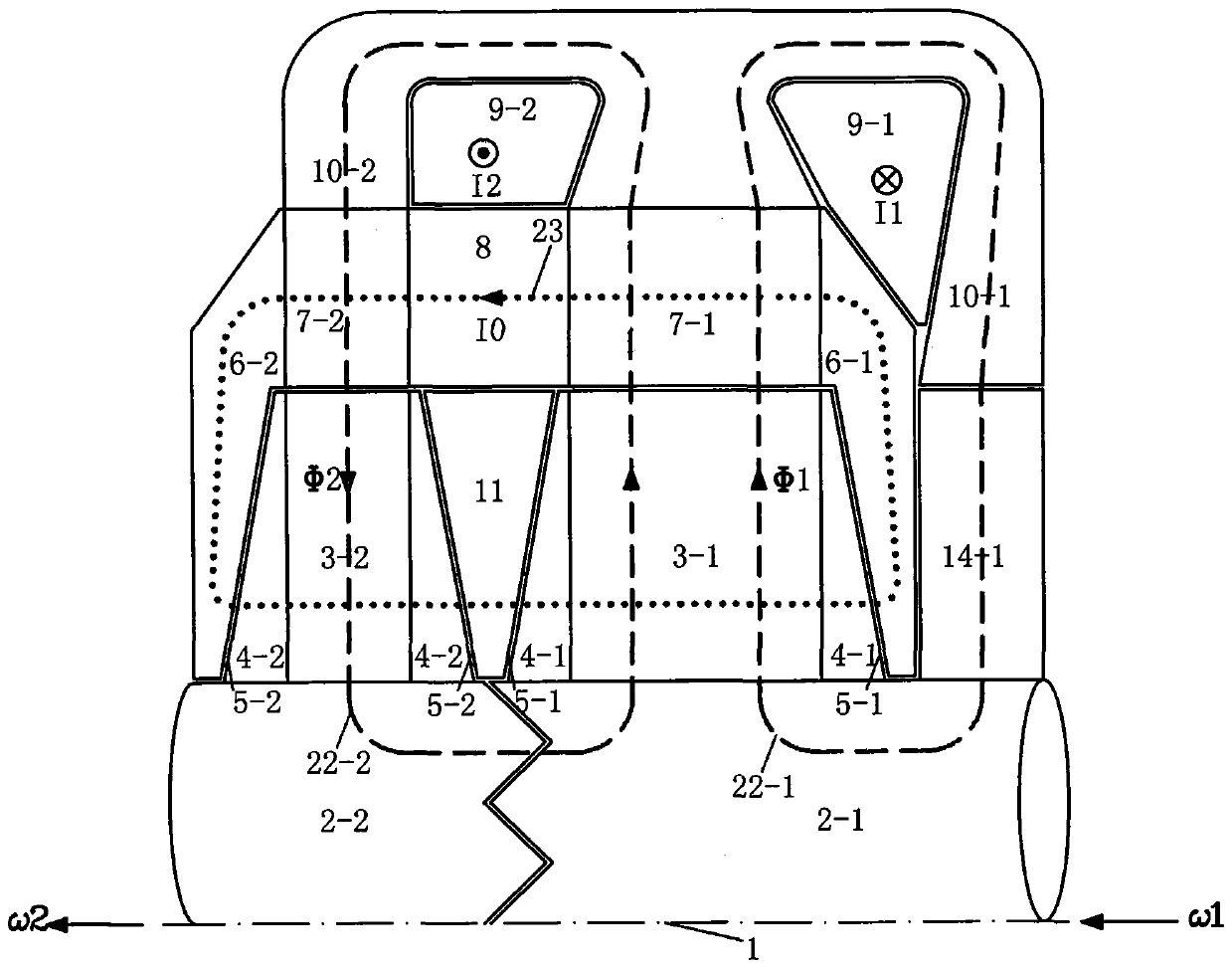

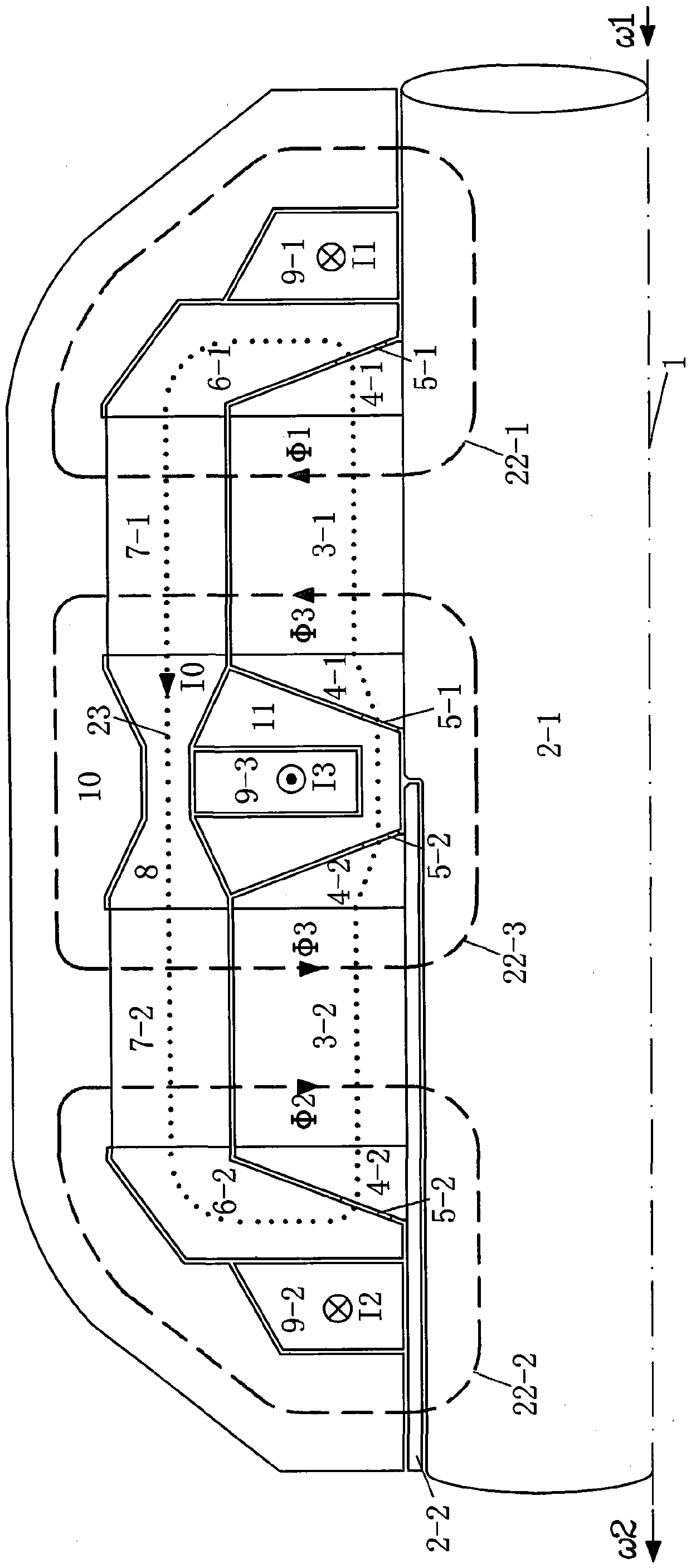

[0139] A 1.5MW wind power generation system with HET ( Figure 21 ) The specific embodiment is as follows.

[0140] The system includes: a horizontal shaft variable-pitch blade wind rotor, a horizontal speed-up gearbox connected to the wind rotor shaft, a unipolar DC electromagnetic transmission (HET) connected to the gearbox output shaft and the generator shaft, a horizontal A type synchronous generator, a mechanical brake device located at the shaft of the wind rotor, a yaw drive active wind-facing mechanism, a nacelle, a tower, and control and auxiliary systems.

[0141] The wind rotor adopts three airfoil profile blades, the maximum value of wind energy utilization coefficient Cp is 0.47, and the corresponding optimal tip speed ratio is 7, and the rated design point applies the optimal tip speed ratio and the maximum Cp value. Select a rated wind speed of 12m / s for lower wind energy applicable to a wide range of wind fields. The rated speed of the wind rotor is 24.31r / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com