Decorative moulding manufacturing method

A technology of decorative lines and production methods, which is applied in the direction of architecture and building construction, can solve the problems of easy rusting of anchors, poor appearance and feeling, and no energy saving, etc., and achieves easy joint processing, convenient cutting and processing, and overall strength Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

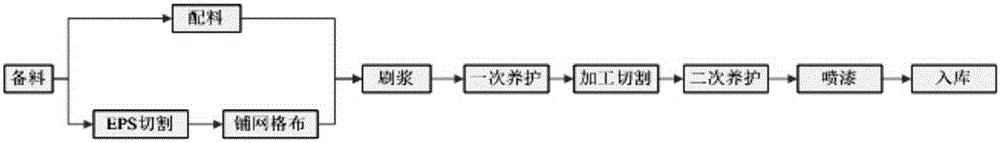

[0015] Such as figure 1 Shown, the preparation method of decorative line of the present invention, comprises the steps:

[0016] (1) Prepare the board core, cut the EPS blank, cut the EPS blank according to the required shape, and wrap the EPS blank with alkali-resistant glass fiber mesh cloth after cutting;

[0017] (2) Prepare the shell, pour the slurry into the brushing machine, brush the EPS blank wrapped with alkali-resistant glass fiber mesh cloth, and prepare the decorative lines;

[0018] (3) After the brushing is completed, put the decorative lines into the curing room for a maintenance;

[0019] (4) After the primary maintenance is completed, process and arrange according to the requirements;

[0020] (5) Carry out secondary maintenance, and then carry out painting treatment according to requirements, and dry it after painting.

Embodiment 2

[0022] (1) Prepare the slurry, stir the magnesium chloride solution, magnesium oxide, plant fiber, sawdust, and additives in sequence to make the slurry.

[0023] (2) Prepare the board core, cut the EPS blank, cut the EPS blank according to the required shape, and wrap the EPS blank with alkali-resistant glass fiber mesh cloth after cutting;

[0024] (3) Prepare the shell, pour the slurry into the brushing machine, and brush the EPS blank wrapped with alkali-resistant glass fiber mesh cloth to prepare decorative lines;

[0025] (4) After the brushing is completed, put the decorative lines into the curing room for a maintenance;

[0026] (5) After the primary maintenance is completed, process and arrange according to the requirements;

[0027] (6) Carry out secondary maintenance, and then carry out painting treatment according to requirements, and dry it after painting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com