A kind of die-casting aluminum alloy and its preparation method and communication product

A casting aluminum alloy and communication technology, which is applied in the field of aluminum alloy materials, can solve the problems that good formability, thermal conductivity, corrosion resistance and mechanical properties cannot be taken into account at the same time, and achieve the effect of excellent formability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

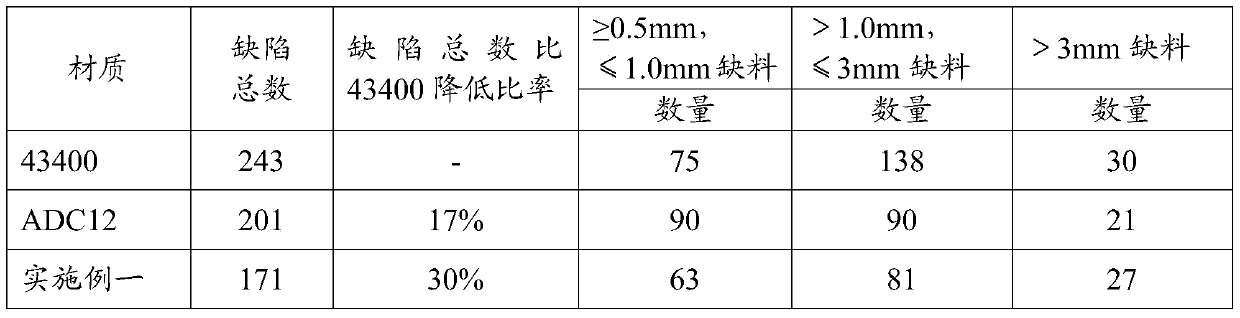

Examples

preparation example Construction

[0068] In a second aspect, an embodiment of the present invention provides a method for preparing a die-casting aluminum alloy, comprising the following steps:

[0069] According to the composition ratio of die-casting aluminum alloy, first add pure aluminum ingot into the melting furnace, after melting the aluminum ingot, add aluminum-silicon alloy, aluminum-copper alloy, aluminum-iron alloy, aluminum-manganese alloy, aluminum-magnesium alloy for melting, and then refine and remove After gas treatment, die-casting is performed to obtain the die-casting aluminum alloy. The die-casting aluminum alloy is composed of the following components in mass percentage: 11.0%-14.0% of silicon; 0.1%-0.9% of manganese; 0.1%-1.0% of magnesium; 0.3%-1.4%; copper ≤ 0.2%; and aluminum and unavoidable impurities.

[0070] The preparation method of the die-casting aluminum alloy of the present invention adopts the existing conventional process, and also includes operations such as conventional im...

Embodiment 1

[0094] A die-casting aluminum alloy, which is composed of the following components in mass percentage: 11.0%-14.0% of silicon; 0.1%-0.9% of manganese; 0.1%-1.0% of magnesium; 0.3%-1.4% of iron; Aluminum and unavoidable impurities.

[0095] Die-casting the die-casting aluminum alloy with the components of this embodiment into a complex thin-walled communication housing, and its preparation method includes the following steps:

[0096] According to the composition ratio of the above-mentioned die-casting aluminum alloys, first add pure aluminum ingots into the melting furnace, and then add aluminum-silicon alloys, aluminum-copper alloys, aluminum-iron alloys, aluminum-manganese alloys, and aluminum-magnesium alloys for melting, and then refine After degassing treatment, die-casting is performed to obtain a thin-walled communication housing.

[0097] The interior of the die-casting aluminum alloy includes an α-Al phase, a eutectic Si phase, and a second phase, the second phase i...

Embodiment 2

[0100] A die-casting aluminum alloy is composed of the following components in mass percentage: 13% silicon; 0.45% manganese; 0.5% magnesium; 0.8% iron; 0.049% copper;

[0101] According to the method of Embodiment 1, the die-casting aluminum alloy with the components of this embodiment is die-cast into a complex thin-walled communication housing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com