Fortified straight-flow biological contact oxidation pond and operation method thereof

A biological contact and oxidation tank technology, applied in chemical instruments and methods, sustainable biological treatment, aerobic process treatment, etc., can solve the problems of long residence time, low treatment capacity, turbid effluent, etc., to reduce effluent SS and investment. And the effect of low operating cost and improving purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

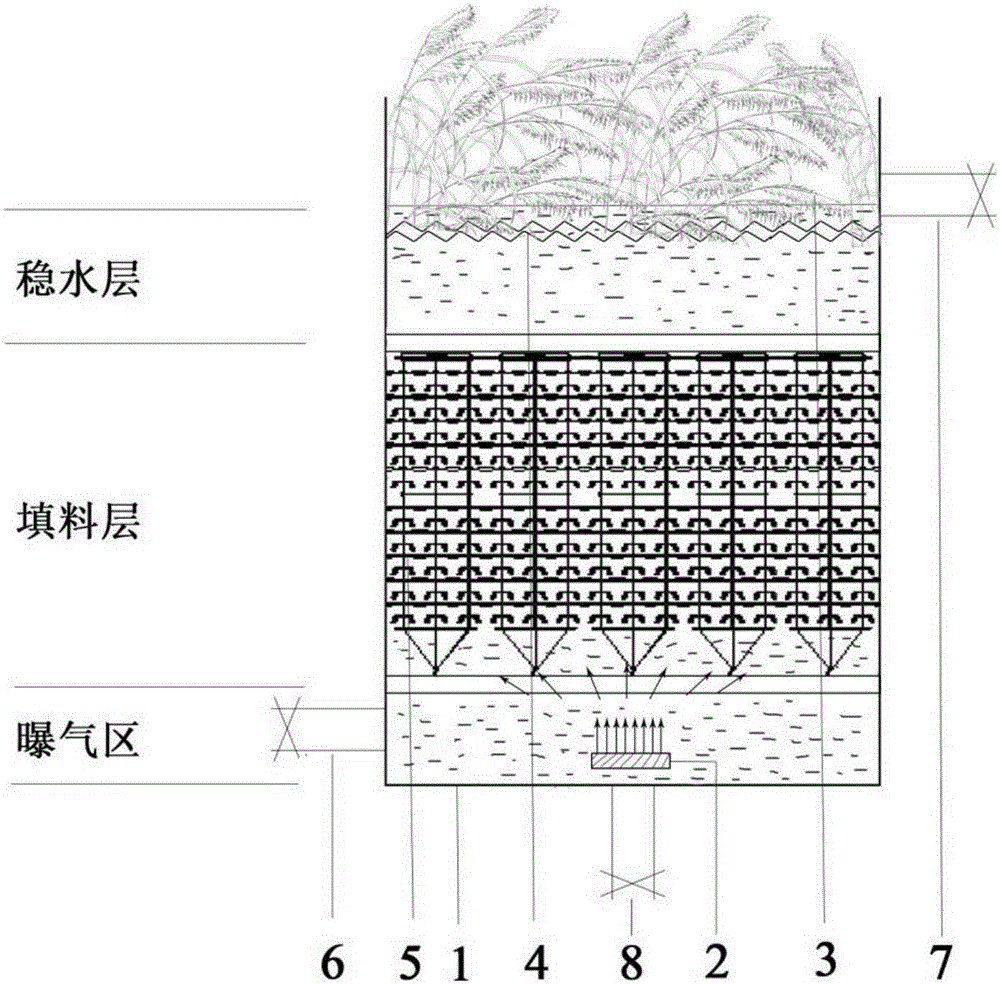

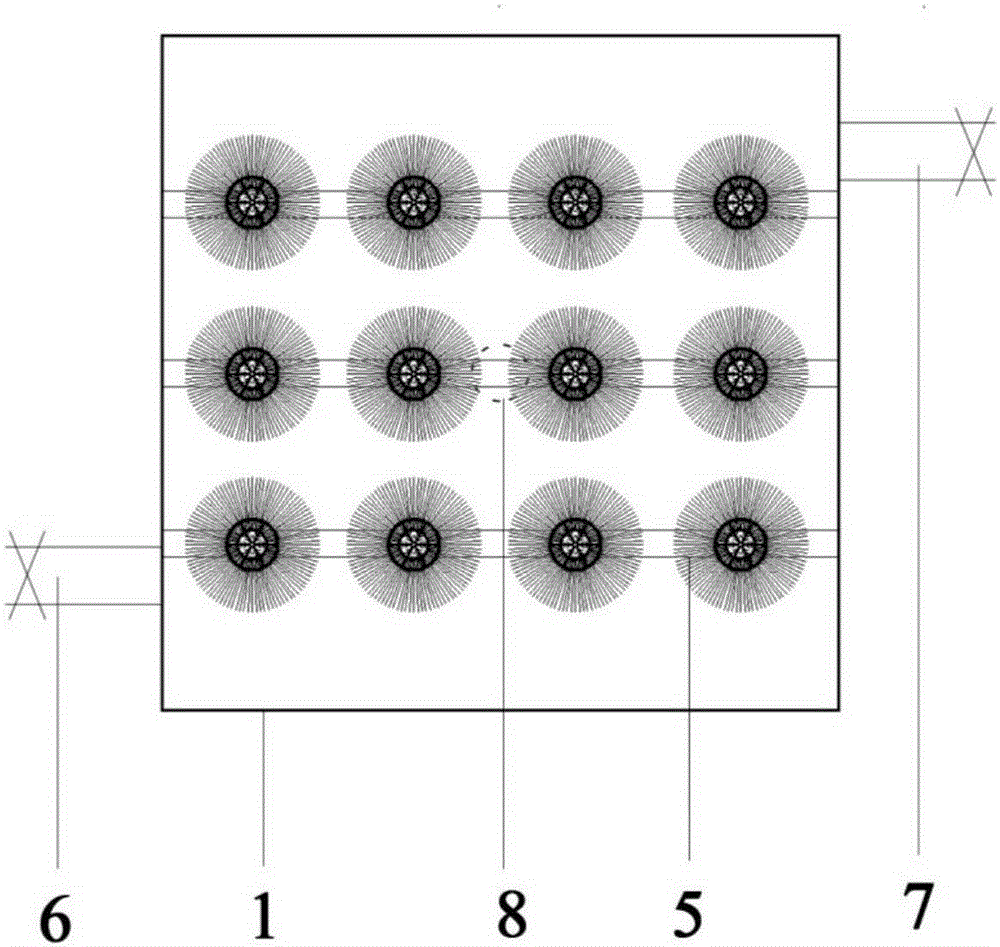

[0023] The enhanced once-through type biological contact oxidation pond of the present embodiment has a structure such as figure 1 and figure 2 As shown, including the pool body 1 made of concrete, the cross section of the pool body 1 is rectangular, and the aspect ratio is 1:1-2:1. According to the actual situation, the effective water depth is 4.4m-4.9m. In the tank body 1, there are aeration area, packing layer and water stabilizing layer from bottom to top. The height ratio of aeration area, packing layer and water stabilizing layer is about 1:4:1.2. After a lot of experiments, it has been confirmed that this ratio can The present invention obtains the best purification treatment effect. The outside of the pool body 1 is provided with a water inlet pipe 6 at the aeration area, the outside of the pool body 1 is provided with a drainage pipe 7 at the water stabilization layer, and the bottom of the pool body 1 is provided with a sewage pipe 8 .

[0024] The bottom of the ...

Embodiment 2

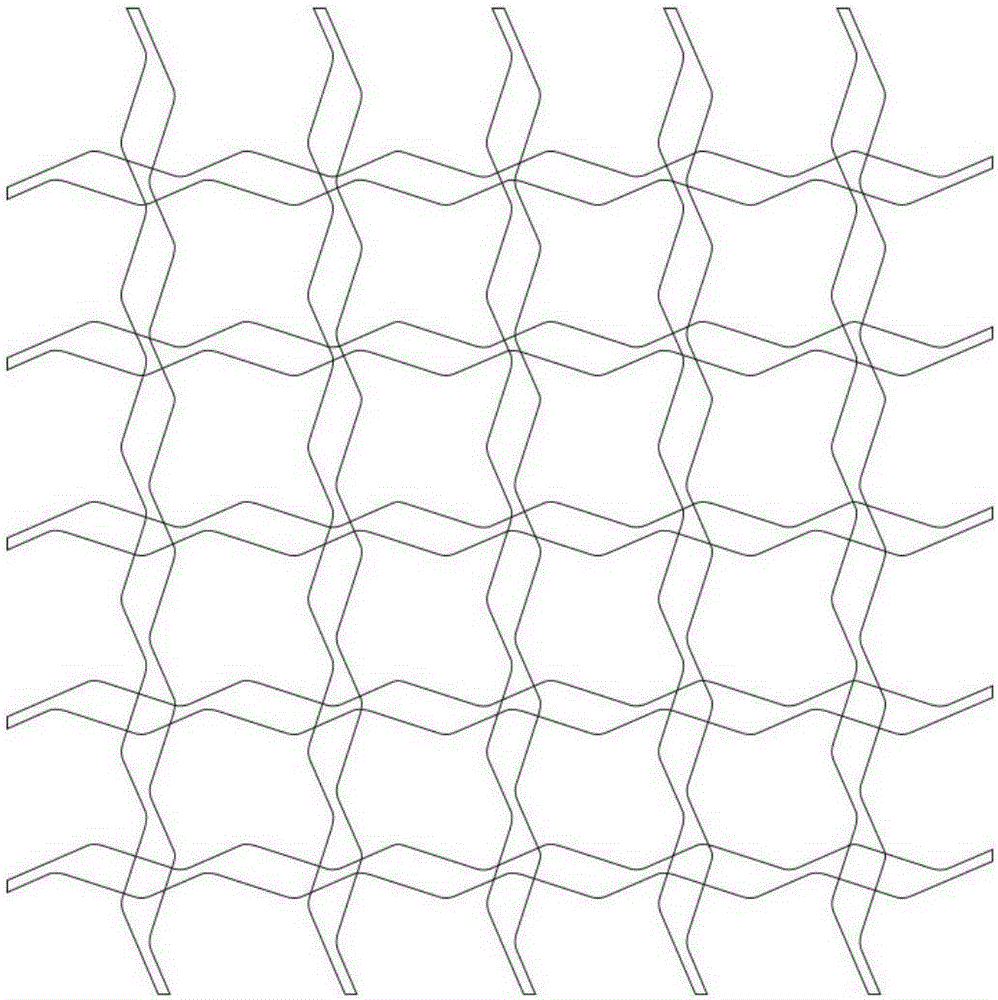

[0028] The difference between this embodiment and Embodiment 1 is that the pool body 1 is made of PVC (polyvinyl chloride), the effective water depth of the pool body 1 is 1.3m-1.8m, the height of the aeration zone is 0.2m-0.3m, and the filler The height of the layer is 0.8m-1.2m, and the height of the water stabilization layer is 0.24m-0.36m. The plant growth frame 4 in the stable water layer adopts Figure 4 As shown in the planting disc-shaped support, plants such as cattails and water turtles are planted on the support.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com