Miniature double-acting hydraulic machine and forming method

A hydraulic press and miniature technology, which is applied in the direction of stamping machines, presses, manufacturing tools, etc., can solve the problems of inability to complete the forming of complex miniature parts, unsuitable ordinary presses, and unstable pressure, etc., to achieve convenient control, reduce costs, and pressure Precisely adjustable curve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

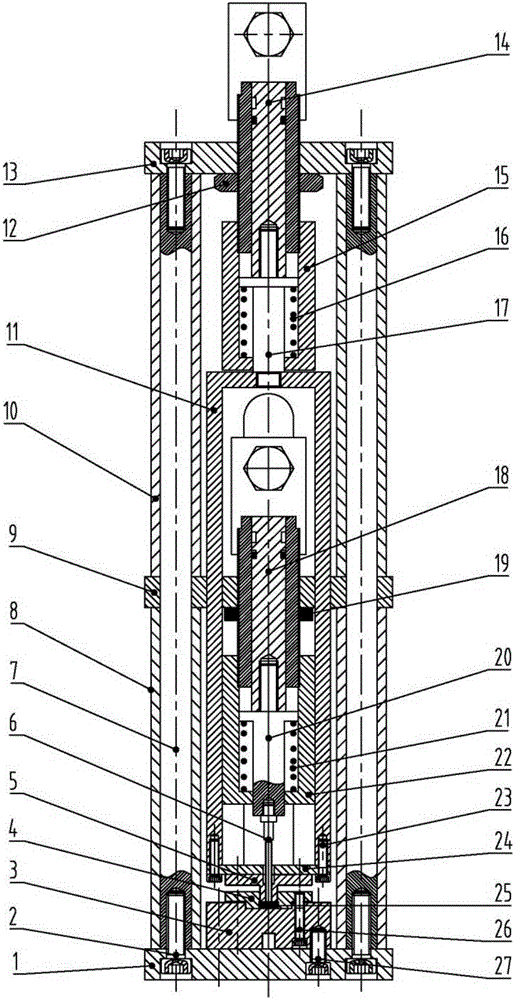

[0023] The miniature double-acting hydraulic press of the present invention will be described in detail below with reference to the accompanying drawings.

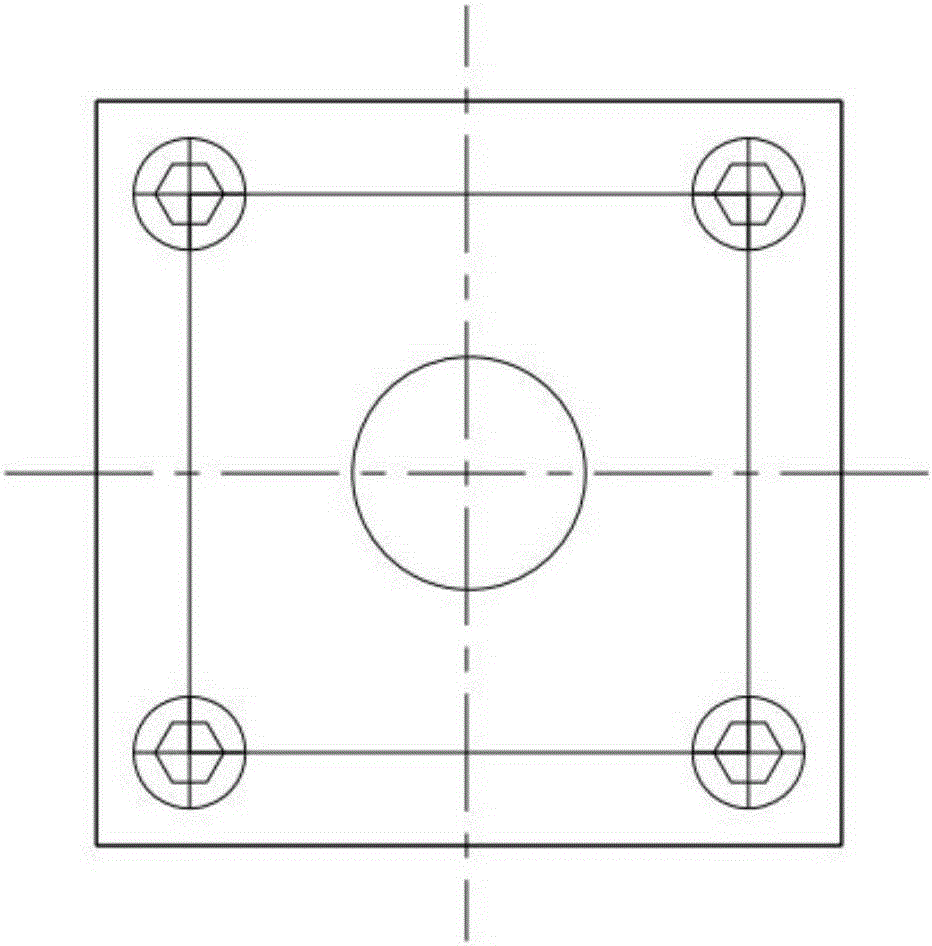

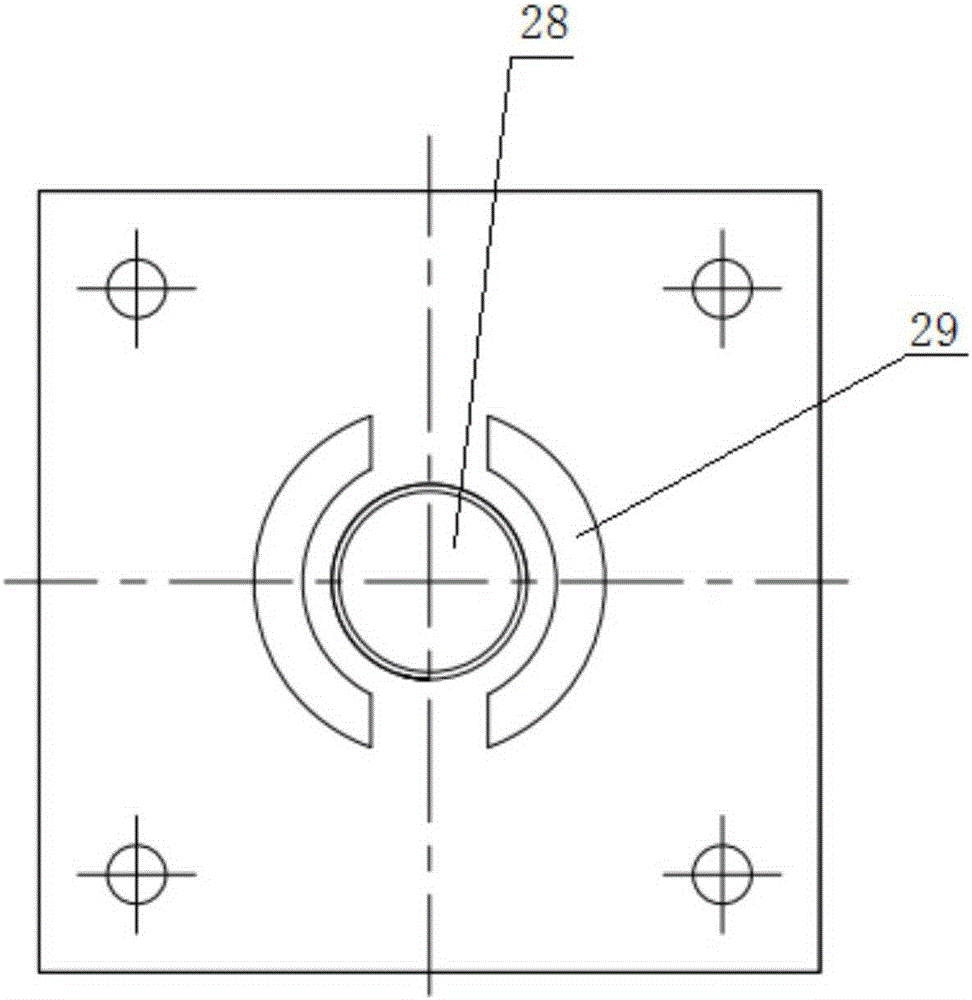

[0024] see figure 1 According to the miniature double-acting hydraulic machine of the present invention, it mainly consists of upper beam 13, middle beam 9, workbench 1, column 7, upper sleeve 10, lower sleeve 8, upper oil cylinder 14, lower oil cylinder 18, upper piston rod connecting rod 17 , Lower piston rod connecting rod 20, guide sleeve 11 and fixed nuts 12,19. The lower end of the upper oil cylinder 14 is tapped with an external thread, and is threadedly connected with the upper beam 13 tapped with a threaded hole, and is back tightened by a fixed nut 12, and is connected with the guide sleeve 11 through the upper piston rod connecting rod 17, and then connected with the drop cylinder through the connecting plate 24. The material punch 5 is connected to provide power for the mould. The lower cylinder 18 lower end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com